Multifunction Thermal Conductivity Tester (Heat Flow Method)

The Multifunction Thermal Conductivity Tester (Heat Flow Method) is a laboratory instrument used to measure thermal conductivity, thermal resistance, and interface contact thermal resistance of small solid materials. It is suitable for thin conductive materials, thermally conductive silicone sheets, thermally conductive resins, beryllium oxide ceramics, aluminum oxide ceramics, and similar materials. With optional sample holders, the instrument can also test powdered and paste-like materials under controlled pressure. Test samples are primarily solid sheets.

Application

The Multifunction Thermal Conductivity Tester is used for:

Thermal conductivity and thermal resistance measurement of solid materials

Interface contact thermal resistance evaluation between solid surfaces

Thermal insulation and heat dissipation characterization of electronic materials

Thermal performance analysis in universities, research institutes, quality inspection agencies, and industrial production laboratories

Applicable materials include thermally conductive polymers, ceramics, composite materials, electronic thermal interface materials, and aluminum-based composite structures.

Standards

MIL-I-49456A Thermal and Insulating Materials for Thin Sheets, Thermally Conductive Resins, and Glass Fiber Reinforced Composites

GB 5598-85 Method for Measuring Thermal Conductivity of Beryllium Oxide Ceramics

ASTM D5470-12 Standard Test Method for Thermal Transmission Properties of Thin Thermally Conductive Solid Electrical Insulation Materials

Parameters

| Parameter | Specification |

|---|---|

| Average sample temperature range |

Option 1: 20–80 °C (Hot

plate: RT–100 °C; Cold plate: 0–80 °C) Option 2: 20–140 °C (Hot plate: RT–200 °C; Cold plate: 0–80 °C) Option 3: 20–190 °C (Hot plate: RT–300 °C; Cold plate: 0–80 °C) |

| Thermal conductivity range |

Standard mode: 0.1–45

W/m·K High-conductivity mode (optional): 5–500 W/m·K |

| Thermal resistance range | 0.05–500 cm²·K/W |

| Measurement accuracy |

Thermal resistance:

10–500 cm²·K/W ≤ ±3%; 0.05–10 cm²·K/W ≤ ±5% Thermal conductivity: 0.1–5 W/m·K ≤ ±3%; 5–500 W/m·K ≤ ±5% Contact thermal resistance ≤ ±5% Aluminum-based composite thermal resistance ≤ ±5% ±0.1 |

| Test head diameter | Φ30 mm (standard); Φ50 mm (optional) |

| Sample size |

0.1–5 W/m·K or 10–500

cm²·K/W: Φ30 × 0.2–5 mm (layering allowed) 5–45 W/m·K or 2–10 cm²·K/W: Φ20–Φ30 × 0.2–15 mm 5–500 W/m·K: Φ10–Φ30 × 15–30 mm (high-conductivity mode) Aluminum-based composite: 15 × 15 mm |

| Pressure measurement range | 0–1000 N |

| Displacement measurement range | 0–40 mm |

| Pressure control | Electric |

| Test modes | Thermal resistance under varying pressure; material thermal conductivity; contact thermal resistance under varying media pressure; aluminum-based composite thermal resistance; aging and reliability testing; high-conductivity material testing (optional); sample-to-sample contact thermal resistance (optional); material compression property testing |

| Power supply | AC 220 V, < 1 kW |

Features

Automatic pressure application and automatic sample thickness measurement

Fully computer-controlled operation with real-time data acquisition

Heat protection structure around the test rod reduces environmental influence and extends temperature range

Thermocouple stack configuration improves heat flow resolution, accuracy, and repeatability

No ice-water mixture required for cold-side compensation

Supports advanced testing functions such as aging, reliability, high-conductivity materials, and interface contact resistance

Stable, repeatable, and automated measurement process

Accessories

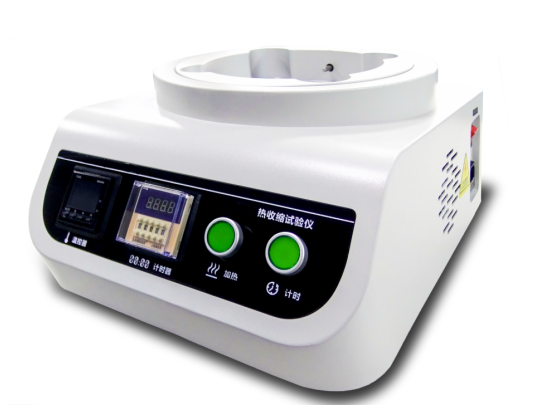

Thermal conductivity tester main unit × 1

Test and control software with communication interface × 1

Constant temperature bath (water or oil, depending on temperature range) with controller × 1

Desktop computer for system control and data acquisition × 1

Test Procedures

Prepare the sample according to thickness, flatness, and surface cleanliness requirements.

Install the sample using the appropriate test head and sample holder.

Set temperature conditions, pressure parameters, and test mode via the control software.

Start the test; the system automatically applies pressure and stabilizes temperature.

Measure heat flow and temperature gradients during steady-state conditions.

The software calculates thermal conductivity, thermal resistance, or interface contact thermal resistance.

Save, export, or print test results after completion.

Maintenance Information

Keep test heads and contact surfaces clean and free from contamination.

Periodically verify pressure, displacement, and temperature sensors.

Maintain the constant temperature bath according to operating guidelines.

Perform calibration checks using reference materials at regular intervals.

FAQ

What is this product?

It is a laboratory instrument based on the heat flow method for measuring thermal conductivity, thermal resistance, and contact thermal resistance of solid and semi-solid materials.

What is this product used for?

It is used to evaluate heat transfer, insulation performance, and interface thermal behavior of materials and components.

Why is this product important?

Accurate thermal property data is essential for material selection, thermal design, reliability analysis, and performance optimization.

What industries is this product suitable for?

It is suitable for electronics, materials science, ceramics, polymers, composite materials, research laboratories, and quality inspection institutions.

What types of this product are available?

The product supports standard and optional configurations, including high-conductivity testing modules and extended interface thermal resistance measurement functions.

Leave Message Get Price