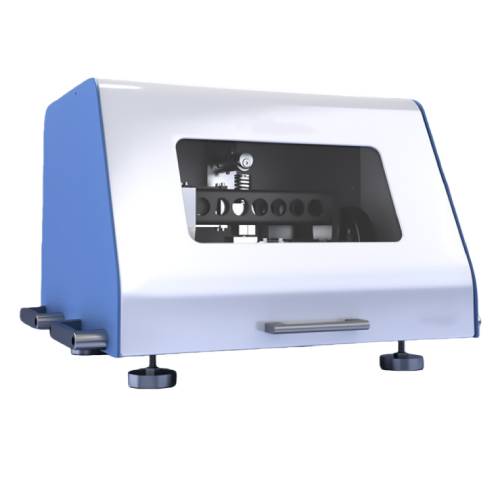

SRV High-Frequency Reciprocating Test Machine

SRV High-Frequency Reciprocating Test Machine is a fully automated, computer-controlled tribological testing system designed to evaluate friction and wear behavior of lubricants, lubricating oils, greases, solid films, and additives under linear oscillatory motion. The tester operates in accordance with major ASTM, DIN, and ISO standards and supports both standardized and customized test methods, making it suitable for routine testing, research applications, and future petroleum product standard development.

Application

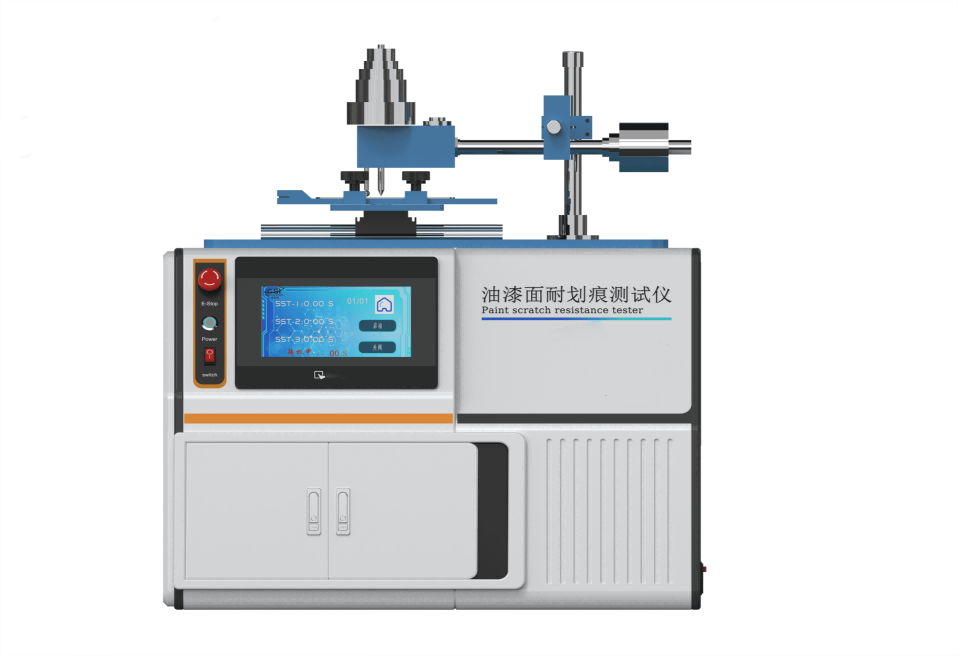

Lubricant Friction and Wear Evaluation

Measurement of friction coefficient, wear scar formation, and extreme pressure behavior of lubricating oils, greases, and additives under high-frequency linear oscillation.

Grease Extreme Pressure (EP) Performance Testing

Assessment of grease load-carrying capacity and anti-wear performance in accordance with standardized SRV test methods.

Solid Film and Coating Evaluation

Determination of extreme pressure and wear resistance characteristics of bonded solid lubricant films.

Plastic and Component Tribology Testing

Evaluation of friction and wear behavior of lubricated plastic components, such as suspension joints and sliding interfaces.

Research and Quality Control

Applied in lubricant formulation development, performance comparison, and quality assurance in laboratories, research institutes, and industrial environments.

Standards

(ASTM D5706) Determination of Extreme Pressure Properties of Lubricating Greases

(SH/T 0784) Lubricating Grease Extreme Pressure Test Method (High-Frequency Linear Oscillation Method)

(ISO 19291) Lubricants — Determination of Tribological Quantities for Lubricating Oils and Greases Using a Translating Oscillation Apparatus

(ASTM D5707) Measurement of Friction and Wear Properties of Lubricating Grease Using an SRV Test Machine

(ASTM D6425) Measurement of Friction and Wear Properties of Extreme Pressure Lubricating Oils Using an SRV Test Machine

(ASTM D7217) Determination of Extreme Pressure Properties of Solid Bonded Films Using an SRV Test Machine

(ASTM D7420) Determination of Mechanical Performance of Grease-Lubricated Plastic Socket Suspension Joints Using an SRV Test Machine

(ASTM D7421) Determination of Extreme Pressure Properties of Lubricating Oils Using an SRV Test Machine

(ASTM D7594) Determination of Fretting Wear Resistance of Greases at High Hertzian Contact Pressure Using an SRV Test Machine

(DIN 51834-1) Tribological Testing in Translatory Oscillating Systems — General Working Principles

(DIN 51834-2) Measurement of Friction and Wear of EP Lubricating Oils

(DIN 51834-3) Determination of Friction Behavior of Materials and Lubricants

(DIN 51834-4) Tribological Testing of Gear Oils and Hydraulic Oils

(DIN 51834-5) Standardized Projects for Automotive Applications

(DIN 51834-6) Measurement of Friction and Wear of Lubricating Greases

(DIN 51834-7) Determination of Extreme Pressure Properties of Lubricating Greases

(DIN 51834-8) Tribological Testing of Bonded Solid Lubricant Films

(DIN 51834-9) Evaluation of Lubricating Greases in Plastic Materials

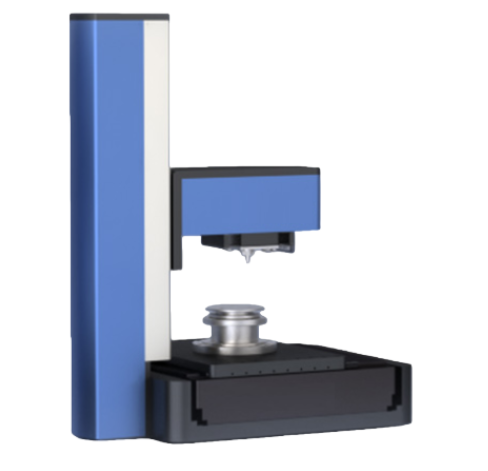

Parameters

| Parameter | Specification |

|---|---|

| Stroke | 10 µm–2.8 mm / 0.1 mm–5 mm |

| Frequency | 300 / 500 Hz |

| Friction Force Detection | High-resolution piezoelectric sensor |

| Drive System | Electromagnetic voice-coil actuator |

| Temperature Range | Room temperature to 350 °C (optional −40 °C and up to 800 °C) |

| Maximum Load | Up to 3000 N |

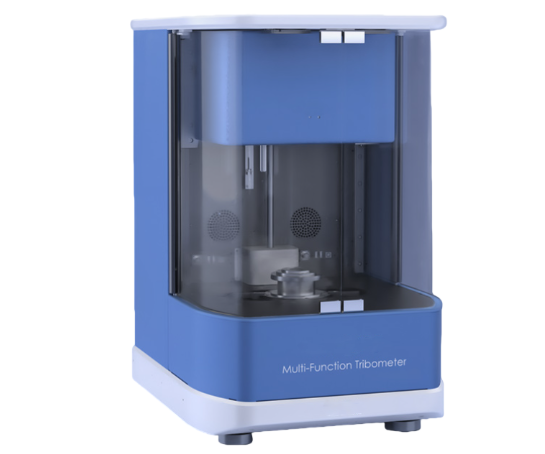

Features

Real-time load control with stable force application

Electromagnetic voice-coil actuator for precise linear reciprocating motion

High-precision stroke control with nanometer-level resolution

Wide-range environmental chamber with closed-loop temperature control

Flexure-based design to eliminate rolling and bearing friction

Piezoelectric ceramic sensor with ultra-low noise amplification for real-time friction measurement

Support for additional online sensors, including acoustic emission and electrical contact resistance

Accessories

(1) Standard oil and reference samples

(2) Liquid test chamber

(3) Customizable sample holders

(4) Acoustic emission (AE) sensor

(5) Electrical contact resistance (ECR) sensor

Test Procedures

Install the appropriate specimen and counter-body in the sample holder according to the selected test method.

Set test parameters including load, frequency, stroke, temperature, and test duration via the control software.

Apply lubricant, grease, or solid film sample as specified by the relevant standard.

Start the automated test sequence; friction force and test conditions are monitored and recorded in real time.

After completion, remove samples for wear scar observation and data evaluation.

Maintenance Information

Regular calibration of the friction force sensor is recommended to maintain measurement accuracy.

The contact-free suspension and magnetic guidance system minimizes wear and reduces routine maintenance requirements.

Environmental chamber and sample fixtures should be cleaned after testing, especially when operating at elevated temperatures.

Periodic inspection of electrical connections and sensors ensures long-term system stability.

FAQ

1. What types of materials and lubricants can be tested using the SRV High-Frequency Reciprocating Friction and Wear Tester?

The SRV tester is designed to evaluate lubricating oils, greases, additives, and bonded solid lubricant films under linear oscillatory motion. It is also suitable for testing lubricated plastic components and material pairings. The system supports standardized methods as well as customized procedures, allowing evaluation of friction, wear, and extreme pressure properties across a wide range of tribological applications.

2. How does the tester ensure accurate and repeatable friction force measurements?

Friction force is measured using a high-resolution piezoelectric ceramic sensor combined with an ultra-low noise amplifier. The friction force sensor can be calibrated, ensuring reliable and traceable measurement results. In addition, the rigid system platform, symmetrical design, and vibration-damping frame contribute to excellent repeatability of friction data and wear scar results, even during long-term testing.

3. Can the SRV tester operate under different temperature conditions?

Yes. The tester is equipped with an environmental chamber featuring closed-loop temperature control. Standard operation ranges from room temperature up to 350 °C, with optional configurations supporting low-temperature testing down to −40 °C and high-temperature testing up to 800 °C. This wide temperature capability allows simulation of real operating conditions for lubricants and materials.

4. Is the system suitable for both standard testing and research applications?

The SRV High-Frequency Reciprocating Friction and Wear Tester supports numerous ASTM, DIN, and ISO standard methods and also allows the creation of custom test procedures. This flexibility makes it suitable for routine quality control, lubricant formulation development, and advanced tribological research.

Leave Message Get Price