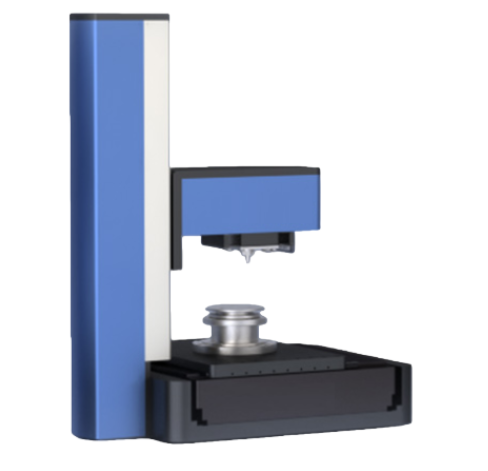

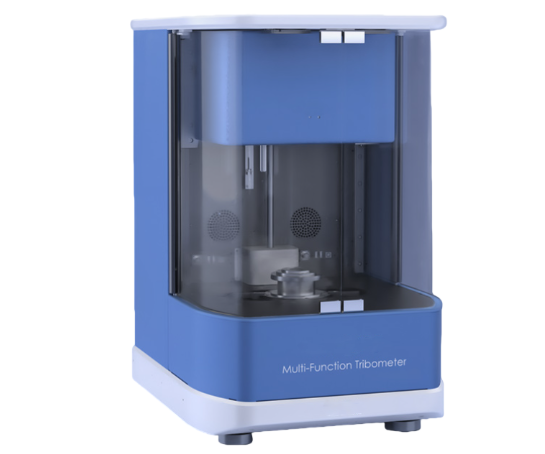

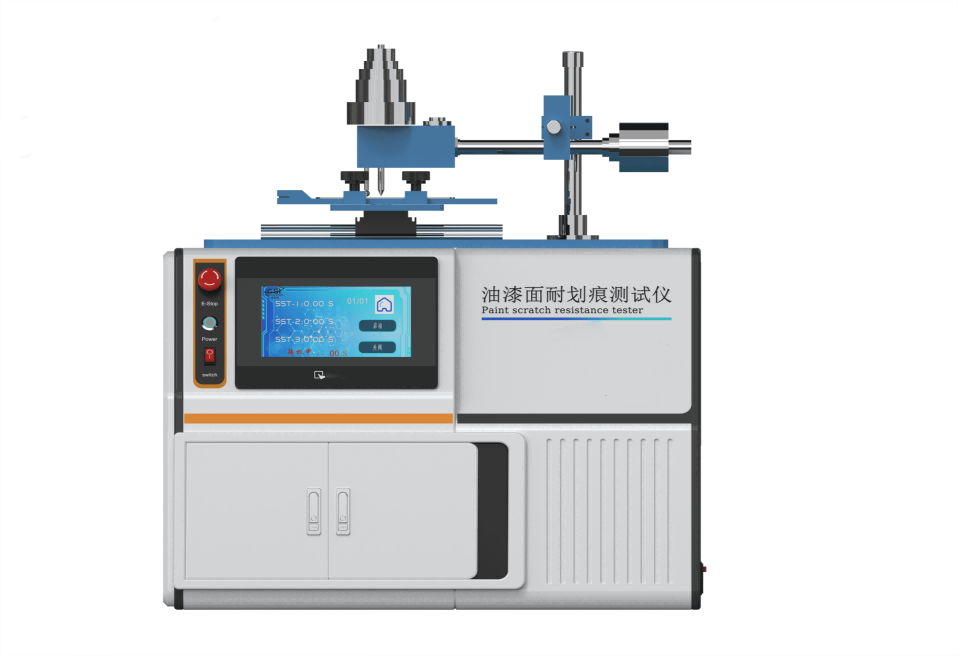

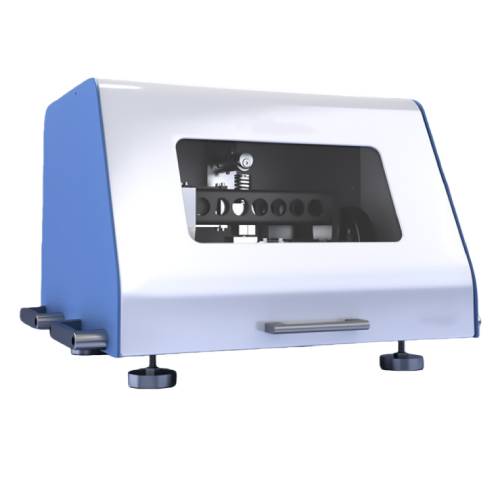

High-Frequency Reciprocating Tester

High-Frequency Reciprocating Tester is a fully automated, computer-controlled tribological testing system designed to evaluate fuel lubricity and the friction and wear performance of additives. It is widely used for friction and wear analysis of petroleum products and for measuring the lubricating properties of fuels, lubricating oils, greases, and additives. The new-generation system combines programmable control with high-precision piezoelectric ceramic sensors, enabling real-time friction force measurement with excellent repeatability and ease of calibration.

Application

The High-Frequency Reciprocating Tester is used in standardized and research-level lubricity testing, including:

Evaluation of diesel fuel lubricity and additive performance

Friction and wear analysis of petroleum products under boundary lubrication conditions

Lubricity measurement of lubricating oils, greases, and fuel additives

Comparative testing of different fuel formulations and additive packages

Research, development, and quality control testing in refineries, laboratories, and industrial facilities

Optional modules allow extended testing such as electrical contact resistance measurement, wear scar morphology observation, and gasoline lubricity testing.

Standards

The tester complies with or supports test methods defined in the following standards:

ASTM D6079 (Standard Test Method for Evaluating Lubricity of Diesel Fuels by the High-Frequency Reciprocating Rig)

GB/T 35137-2025 (Diesel fuel lubricity evaluation)

SH/T 0765 (Diesel fuel lubricity evaluation method)

ASTM D7688 (Standard Test Method for Evaluating Lubricity of Diesel Fuels)

ISO 12156-1 (Diesel fuel — Assessment of lubricity using the high-frequency reciprocating rig — Part 1: Test method)

CEC F-06-A-96 (Method for evaluating the lubricating performance of diesel fuel)

BS EN 590 (Automotive fuels — Diesel — Requirements and test methods)

JPI-5S-50-98 (Test method for evaluating diesel fuel lubricity)

Parameters

| Item | Description |

|---|---|

| Load Control | Real-time normal load control |

| Frequency Range | 1–200 Hz |

| Stroke Length | 10 µm to 2.8 mm |

| Friction Force Measurement | High-precision piezoelectric ceramic sensor |

| Temperature Range | Ambient to 180 °C; optional low-temperature and high-temperature up to 400 °C |

| Maximum Load | Up to 20 N (other load ranges available) |

Features

Standardized high-frequency reciprocating motion for lubricity evaluation

Fully automated, computer-controlled test system

Programmable test parameters for flexible testing conditions

Real-time friction force measurement using piezoelectric ceramic sensors

High repeatability and reliable calibration procedure

Supports standard reference oils and test samples

Optional expansion modules for advanced analysis and extended applications

Accessories

Standard test specimen and reference oil set

Piezoelectric ceramic friction force sensor

Electrical contact resistance measurement module (optional)

Metallographic microscope for wear scar analysis (optional)

Gasoline lubricity test module (optional)

Test Procedures

Install the standard test specimen and select the appropriate test configuration.

Set test parameters such as load, frequency, stroke length, and temperature.

Calibrate the system according to the standard procedure using reference oil.

Start the automated test sequence under computer control.

Measure friction force in real time throughout the test.

Complete the test after the specified duration or cycle count.

Evaluate lubricity performance based on test results and wear scar analysis.

FAQ

1. What is the primary function of the High-Frequency Reciprocating Tester?

The High-Frequency Reciprocating Tester is primarily used to evaluate the lubricity of diesel fuels and the friction and wear performance of fuel additives. It provides a standardized method for analyzing how fuels and lubricants behave under boundary lubrication conditions. By simulating high-frequency reciprocating motion, the tester generates data that are directly comparable to international standards such as ASTM, ISO, and CEC, making it suitable for regulatory compliance, product development, and quality control.

2. Which standards can be evaluated using this tester?

The tester supports a wide range of internationally recognized lubricity standards, including ASTM D6079. ISO 12156-1. GB/T 35137-2025. SH/T 0765. ASTM D7688. and CEC F-06-A-96. These standards are commonly used for diesel fuel lubricity assessment and ensure that test results are accepted in both regulatory and industrial applications.

3. How is friction force measured during the test?

Friction force is measured in real time using a high-precision piezoelectric ceramic sensor. This sensor provides fast response and high sensitivity, allowing accurate monitoring of friction behavior throughout the entire test cycle. The real-time data acquisition contributes to high repeatability and reliable comparison between different fuels, lubricants, or additive formulations.

4. What temperature conditions can be applied during testing?

The standard configuration supports testing from ambient temperature up to 180 °C. Optional configurations allow testing at lower temperatures or at elevated temperatures up to 400 °C, enabling evaluation of lubricity performance under a broader range of service conditions.

Leave Message Get Price