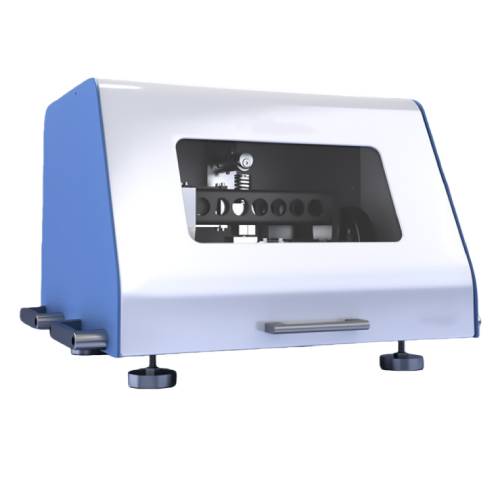

Vacuum Friction and Wear Tester

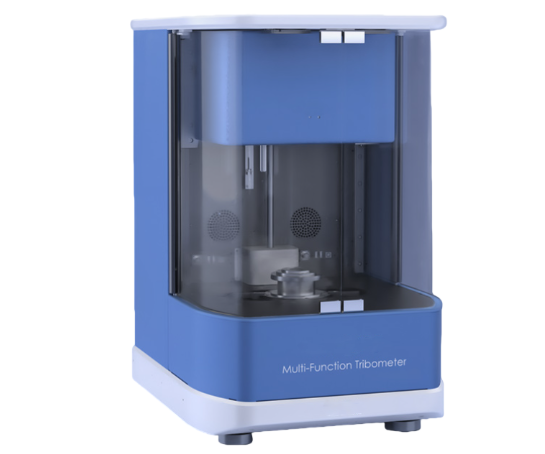

Vacuum Friction and Wear Tester is a specialized tribological testing system designed to study friction, wear, and related surface interactions under vacuum conditions. By precisely controlling normal load, sliding speed, and temperature, the system enables detailed analysis of material behavior in high vacuum or inert gas environments. Its unique mechanical design and high-precision force sensors ensure excellent data accuracy and repeatability. Multiple tests—including friction, wear, lubrication, scratch, and hardness—can be performed on a single platform, making it suitable for advanced vacuum tribology research and material evaluation under extreme conditions.

Application

The Vacuum Friction and Wear Tester is used for investigating tribological behavior under controlled vacuum or inert gas environments, including:

Friction and wear evaluation of materials under high vacuum, high-temperature, and low-temperature conditions

Study of surface friction, wear, and adhesion mechanisms unique to vacuum environments

Tribological testing of coatings, bulk materials, and surface-modified components

Vacuum lubrication performance evaluation for materials and lubricated surfaces

Scratch, indentation, and hardness testing under vacuum conditions

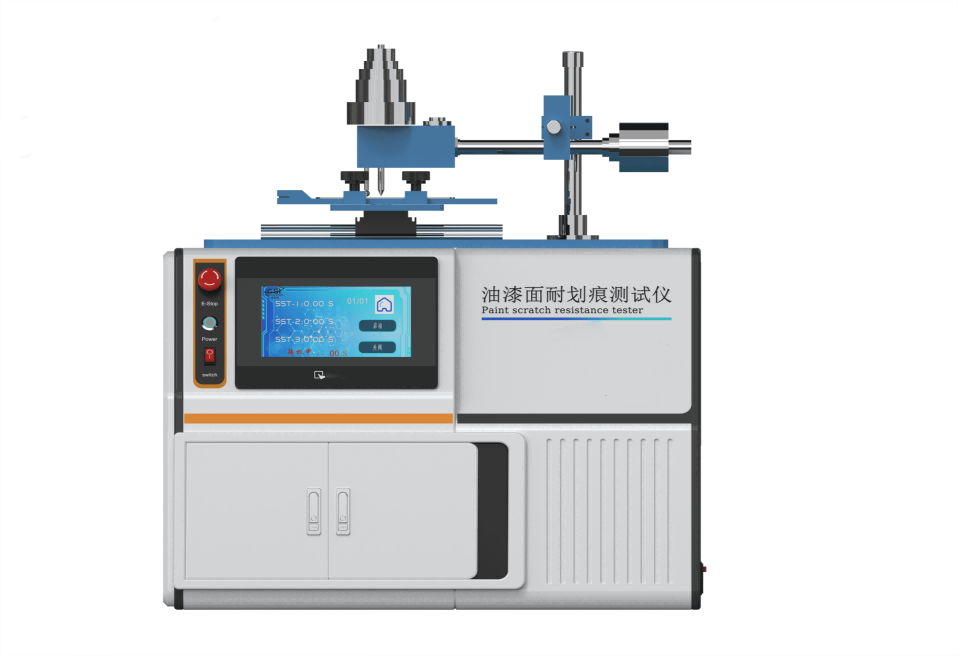

Typical test configurations include rotational friction, linear reciprocating friction and wear, indentation, and scratch testing, all conducted on the same testing platform.

Standards

The tester is designed to support test methods referenced in the following standards:

ASTM G99 (Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus)

ISO 20808 (Fine ceramics — Determination of friction and wear characteristics of monolithic ceramics by ball-on-disk method)

GB/T 3142 (Determination of load-carrying capacity of lubricants — Four-ball method)

SH/T 0189 (Test method for anti-wear properties of lubricating oils — Four-ball method)

ASTM D3702-24 (Standard Test Method for Wear Rate and Coefficient of Friction of Materials in Self-Lubricated Contact)

ISO 1461:2022 (Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods)

Parameters

| Item | Description |

|---|---|

| Vacuum Level | Down to 10⁻⁷ Torr |

| Load Range | mN to 200 N |

| Temperature Range | −150 °C to 800 °C |

| Test Modules | Interchangeable friction, wear, hardness, and scratch modules |

| Test Modes | Rotational friction, linear reciprocating friction and wear, indentation, scratch |

| Environmental Control | High vacuum or inert gas atmosphere |

Features

Low-drift mechanical force sensors designed for sealed vacuum environments

Rapid vacuum generation, achieving 10⁻⁷ Torr within approximately 45 minutes using integrated vacuum and molecular pumps

High-precision temperature control, with low-temperature capability down to −150 °C and high-temperature operation up to 400 °C (optional up to 1000 °C)

Rotational and reciprocating test modules combined with a high-precision XY platform for automatic test radius adjustment

Closed-loop loading control enabling real-time force regulation and automatic generation of friction force versus load or speed curves

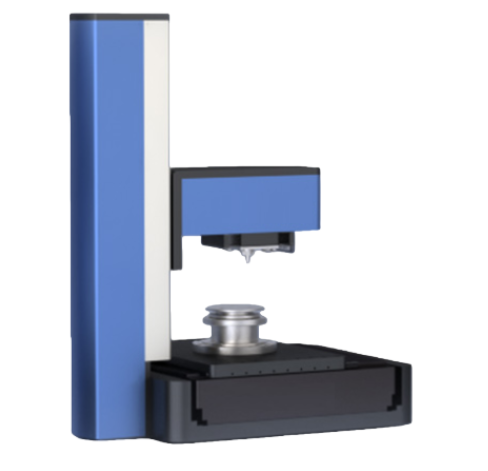

Support for additional modules including scratch, indentation, and friction testing

Accessories

Rotational friction and wear test module

Linear reciprocating friction and wear module

Scratch testing module

Indentation and hardness testing module

Vacuum and inert gas control components

Test Procedures

Install the required test module according to the test objective.

Mount the specimen and counter body securely inside the vacuum chamber.

Set test parameters including load, speed, temperature, and environment type.

Evacuate the chamber to the specified vacuum level or introduce inert gas as required.

Start the test and monitor friction force, load, and temperature in real time.

Complete the test based on predefined conditions or test duration.

Record and export test data for further analysis.

Maintenance Information

Regularly inspect vacuum seals, pumps, and fittings to maintain stable vacuum performance.

Clean test modules and contact components after each test to avoid contamination.

Periodically calibrate force sensors and temperature control systems.

Maintain vacuum and molecular pumps according to operating hours and manufacturer guidelines.

FAQ

1. What is the main purpose of the Vacuum Friction and Wear Tester?

The Vacuum Friction and Wear Tester is designed to evaluate friction, wear, and adhesion behavior of materials under vacuum conditions. Since surface interactions in vacuum environments differ significantly from those in ambient conditions, this system enables accurate simulation of extreme environments such as high vacuum and high or low temperatures. It is particularly useful for studying materials and coatings intended for vacuum components and advanced engineering applications.

2. What vacuum and temperature ranges can be achieved during testing?

The system can achieve a vacuum level as low as 10⁻⁷ Torr and supports a temperature range from −150 °C to 800 °C. This wide operating range allows simulation of extreme service conditions encountered in aerospace, space, and advanced material applications. Optional high-temperature configurations can further extend the upper temperature limit.

3. What types of tests can be performed on the same platform?

Multiple tests can be conducted on a single platform by using interchangeable modules. These include rotational and linear reciprocating friction and wear tests, lubrication studies, indentation, scratch testing, and hardness measurements. This modular approach improves testing efficiency while maintaining high data consistency and repeatability.

4. How does the system ensure measurement accuracy and repeatability in vacuum conditions?

The tester uses specially designed low-drift force sensors suitable for sealed vacuum environments, combined with closed-loop loading control. Real-time monitoring and precise control of load and motion parameters ensure stable testing conditions, enabling the acquisition of high-precision and highly repeatable tribological data.

Leave Message Get Price