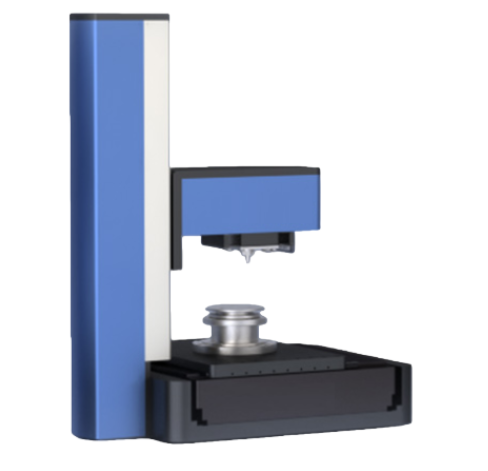

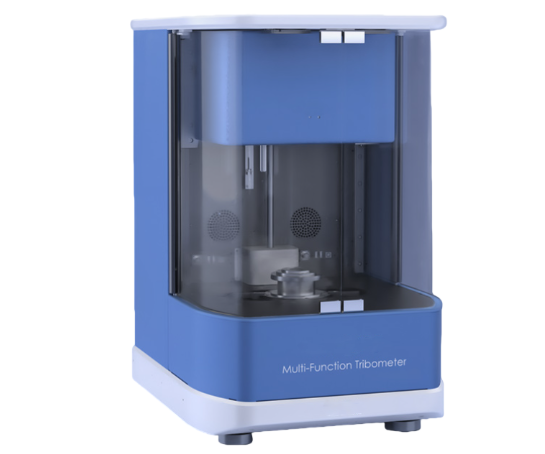

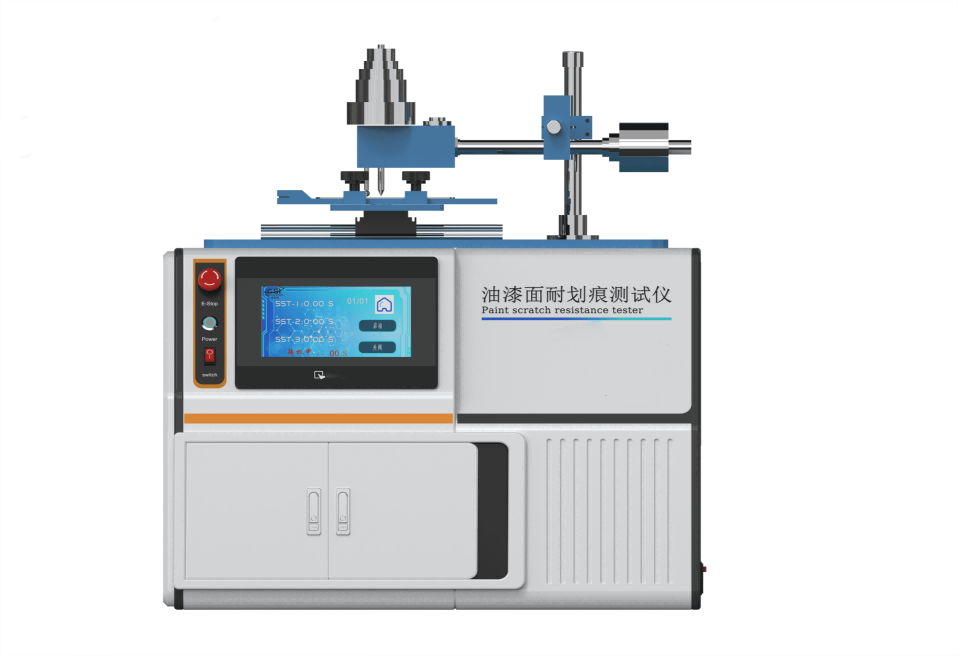

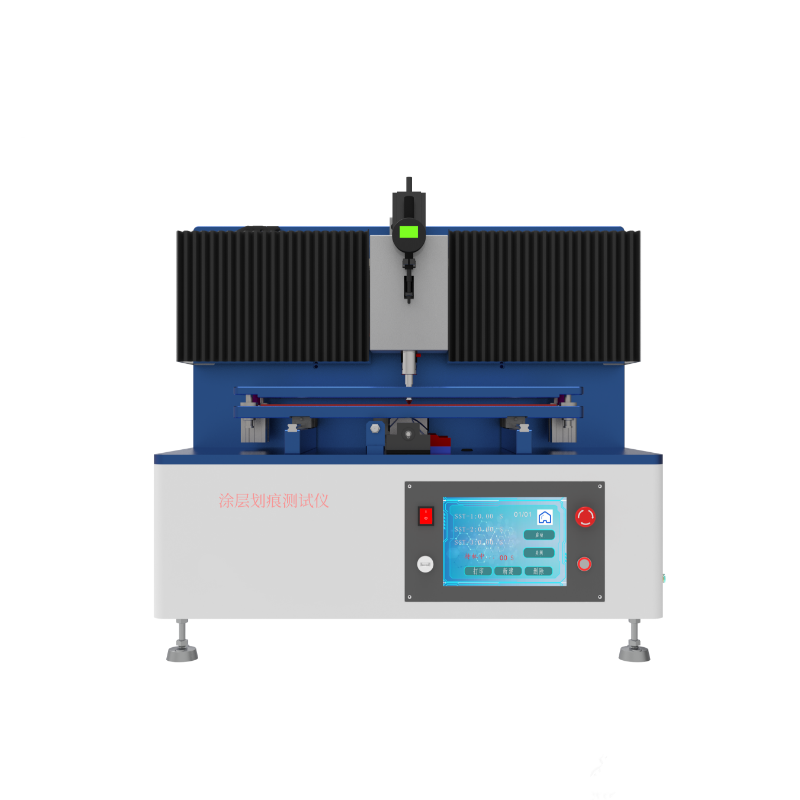

High-Specification Scratch Resistance Tester

High-Specification Scratch Resistance Tester is a laboratory testing device for quantitatively evaluating the scratch resistance of material surfaces. It is suitable for various rigid organic materials, coatings, adhesives, powder coatings, anodized materials, soft metals, plastics, and glass. The instrument applies controlled weight loading to create repeatable scratches on the specimen surface using a scratch head, thereby determining the scratch resistance and surface limit performance of materials and coatings.

Application

The Scratch Resistance Tester is primarily used for the following materials and fields:

Rigid organic materials;

Coatings and adhesives;

Powder coatings;

Anodized materials;

Soft metals;

Plastics and glass;

Quality assessment of protective coatings and adhesives;

Material limit performance testing.

Standards

GB/T 17657‑2022 – Test Methods for Properties of Wood-Based Panels and Decorative Facing Panels

GB 4943.1 – Safety of Information Technology Equipment – Part 1: General Requirements (Clause 2.10.6.6)

GB 4706.1 – Safety of Household and Similar Electrical Appliances – Part 1: General Requirements (Clause 21.2)

AS/NZS 2924.2 – Performance of Kitchen Worktops and Surface Materials – Part 2: Determination of Resistance to Abrasion and Scratching

ASTM C217 – Test Method for Resistance to Abrasion of Ceramic Glazed Tiles

BS EN 438-2 – Physical and Mechanical Properties of High Pressure Laminates (HPL) – Part 2: Test Methods

BS EN 13310 – Performance Requirements for Kitchen Worktops and Surface Materials

BS EN 14323 – Test Methods for Scratch Resistance, Abrasion Resistance and Chemical Resistance of Furniture Surfaces

DIN 68861‑4 – Mechanical Properties of Furniture Surfaces – Part 4: Scratch Resistance

DIN 53799 – Methods for Determining the Hardness of Plastics (Scratch/Indentation)

Parameters

| Item | Details |

|---|---|

| Control System | PLC + Windows System |

| Operation Interface | 12-inch color embedded industrial computer, Chinese/English switchable |

| Printing Function | WiFi-connected printer |

| Motor | Stepper motor + reducer |

| Force Weights | Standard configuration: 5N, 6N, 7N, 8N, 10N (other specifications optional) |

| Test Speed | Factory set at 5r/min, adjustable range: 0–60R/min |

| Spacing | Scratch spacing can be set arbitrarily |

| Sample Size | 100*100mm, with a 6.5mm hole in the center |

| Scratching Head | Standard: diamond stylus; optional: 4.84.8R2.5 |

| Speed Display | Adjustable on the industrial computer |

| Dimensions | 550310520mm |

| Power Requirement | 220V, 60A |

Features

PLC + Windows dual-system control with a simple and intuitive interface;

Color touchscreen industrial computer with Chinese/English language switching for easy parameter setup;

WiFi printer connectivity for convenient data logging;

Stepper motor drive paired with a reduction gearbox ensures stable low-speed rotation;

Adjustable weights enable testing with varying force values;

Scratch spacing freely configurable to meet diverse standard requirements;

Optional diamond scraper head, durable and replaceable;

High-end version offers enhanced precision and broader applicability.

Accessories

(1) Standard diamond scratching head

(2) Standard force weight set (5 N, 6 N, 7 N, 8 N, 10 N)

(3) Specimen-holding disc

(4) Balance bar assembly

(5) WiFi printer

(6) Power cable and basic tool kit

Test Principle

The High-Specification Scratch Resistance Tester applies controlled load to the specimen via a balance bar, fixed weights, and adjustable weights. The specimen is mounted on a specimen-holding disc, with the balance bar height adjusted according to specimen thickness to maintain the scraper head in a horizontal position. During testing, the fixed weights remain stationary while the adjustable weights move to control the applied load. As the sample disk rotates counterclockwise, the scraper head creates arcuate scratches on the sample surface, evaluating the material's surface scratch resistance.

Test Procedures

Operating Instructions:

Adjust the balance bar height according to sample thickness to ensure horizontal scraper head installation;

Secure the specimen to the specimen-holding disc;

Install the appropriate scratch head and weights, then select the test force value;

Start the equipment, adjust the rotation speed and scratch spacing;

Record scratch conditions and required data during testing;

After testing, shut down the equipment and remove the specimen and scratch head;

Periodically inspect the lubrication of the stepper motor and gear reducer to maintain equipment performance.

Experimental Procedure:

Mount the specimen on the specimen-holding disc and adjust the balance bar height;

Select and secure the scratching head and weights;

Set scratch spacing, rotation speed, and cycle count;

Initiate the test; the specimen-holding disc rotates counterclockwise;

The scratching head forms an arc-shaped scratch on the specimen surface;

After testing, record the scratch condition and relevant data;

If repeat testing is required, repeat the above steps.

FAQ

1. What materials can you test with this Scratch Resistance Tester?

You can test rigid organic materials, coatings, powder coatings, anodized surfaces, soft metals, plastics, and glass, provided the specimen dimensions meet the fixture requirements.

2. How is the applied scratch force controlled during testing?

The applied force is controlled through a combination of fixed and adjustable weights mounted on a balance bar, allowing precise and repeatable load settings.

3. Can you adjust the scratch speed and spacing?

Yes, both scratch speed and spacing can be freely adjusted through the industrial computer interface to meet different standard requirements.

4. Is the tester suitable for standard compliance testing?

Yes, the instrument supports multiple national and international standards commonly used for scratch resistance and surface performance evaluation.

5. How do you ensure repeatability of test results?

Repeatability is achieved through stable motor control, standardized scratching heads, precise weight loading, and controlled rotational motion.

Leave Message Get Price