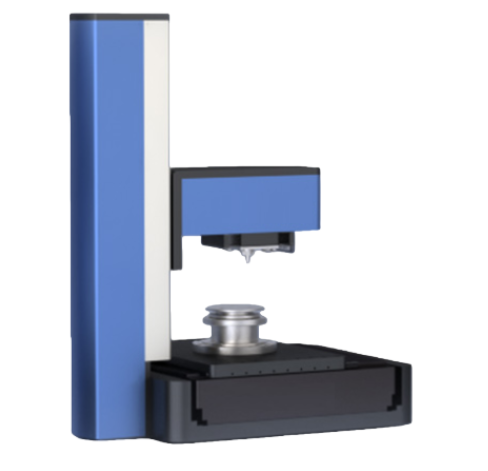

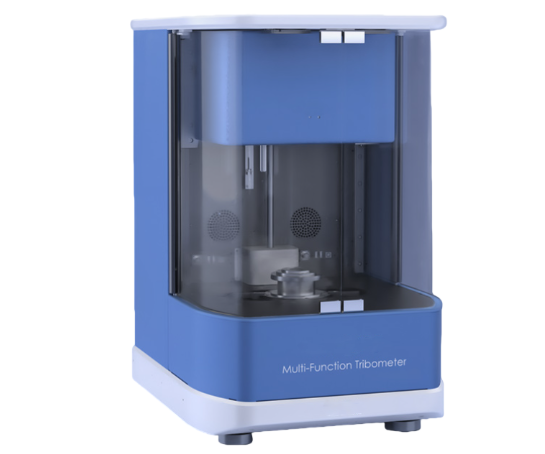

Multi-Function Friction and Wear Tester

Multi-Function Friction and Wear Tester is a highly configurable tribological testing system designed for comprehensive evaluation of friction and wear behavior of materials. The system offers an extra-large working space, an ultra-wide load range, and the capability to integrate an in-situ 3D optical surface profiler. With interchangeable test modules and optional environmental chambers, it supports tribological testing from nano to macro scales under controlled temperature, humidity, pressure, or vacuum conditions. The instrument is widely used across aerospace, automotive, biomaterials, coatings, optics, polymers, semiconductors, and related research fields.

Application

The system is suitable for tribological performance evaluation in a wide range of testing scenarios, including but not limited to:

Friction and wear characterization of metallic materials, ceramics, polymers, coatings, and composites

Lubrication performance assessment of lubricating oils and greases

Wear mechanism analysis of bearings, gears, seals, and functional coatings

Tribological simulation of biomedical components such as artificial joints and dental materials

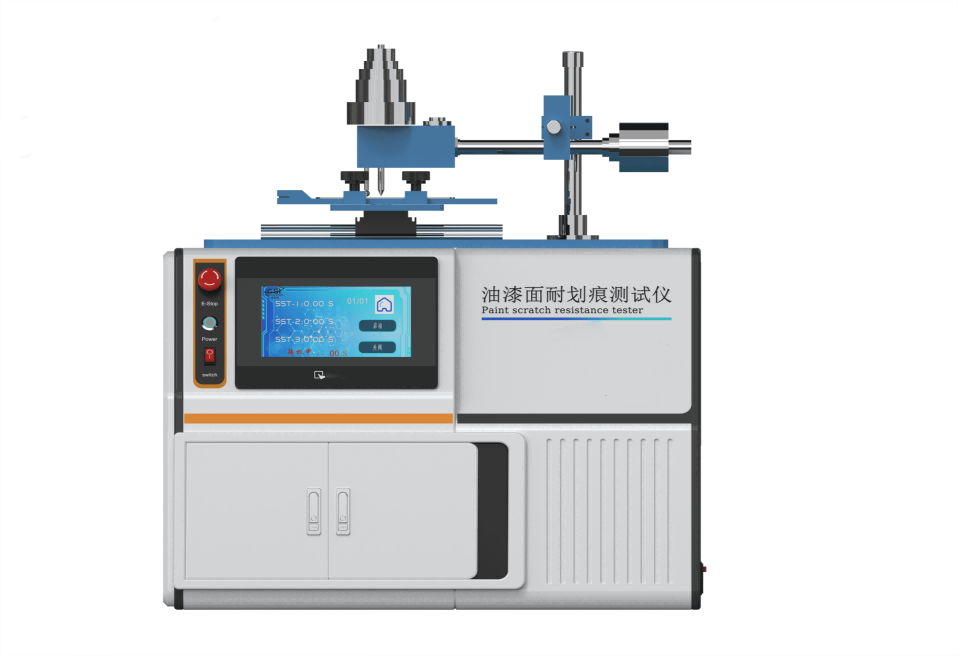

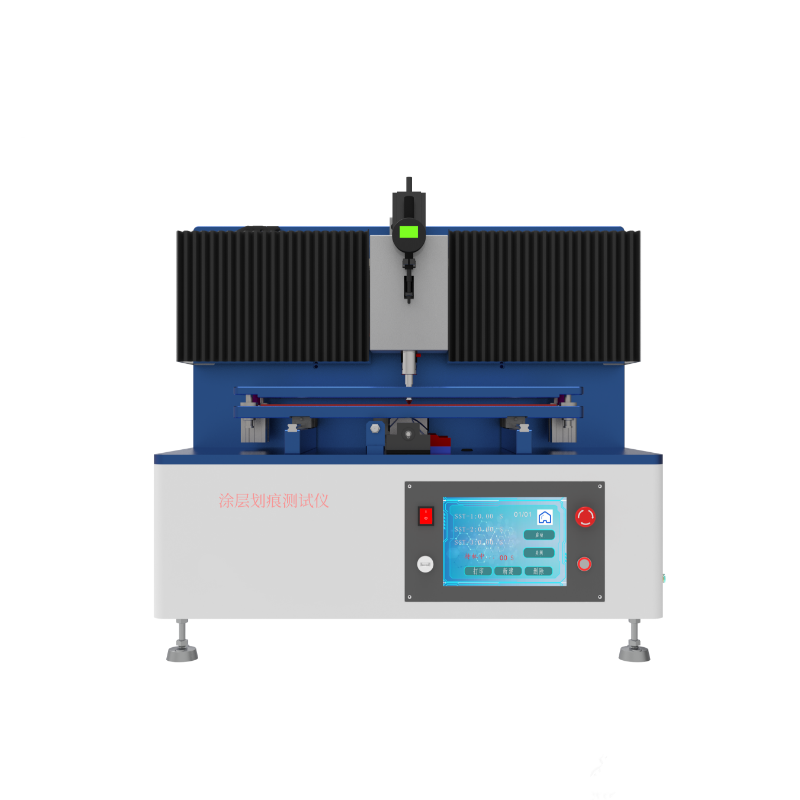

Surface damage, scratch resistance, and micro-motion wear studies

Supported test configurations include ball-on-disk, pin-on-disk rotation, reciprocating ring-on-block, fretting, scratch testing, and other modular test modes.

Standards

The Multi-Function Friction and Wear Tester is designed to support test methods referenced in the following standards:

ASTM G99 (Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus)

ISO 20808 (Fine ceramics — Determination of friction and wear characteristics of monolithic ceramics by ball-on-disk method)

GB/T 3142 (Determination of load-carrying capacity of lubricants — Four-ball method)

SH/T 0189 (Test method for anti-wear properties of lubricating oils — Four-ball method)

Parameters

| Item | Description |

|---|---|

| Z-axis Drive System | High-precision multi-Z-axis system for accurate loading; supports in-situ 3D surface profiling and Raman spectroscopy integration |

| Platform Design | Open-architecture platform providing a large and flexible working area |

| Interchangeable Test Modules | Replaceable lower test modules enabling multiple test modes (rotation, reciprocation, ring-block, fretting, scratch); automatic module recognition |

| Environmental Control | Temperature: −120 °C to 1200 °C; Humidity: 5–95 % RH; Pressure: up to 200 psi; Vacuum: down to 10⁻⁷ torr |

| Force Sensors | Interchangeable sensors from mN to 12.000 N (capacitive, piezoelectric, strain-gauge types) |

| In-situ 3D Profiling | Automatic imaging with nanometer-level resolution; four optical modes: confocal, white-light interferometry, dark-field, bright-field |

| XY Positioning Stage | Travel range 130 mm × 270 mm for precise positioning between friction testing and surface scanning locations |

| Data Acquisition & Motion Control | High-speed, low-noise controller with fast feedback; data sampling rate up to 200 kHz |

| Z-axis Travel | 150 mm |

Features

Supports standard tribological configurations such as ball-on-disk, pin-on-disk rotation, high-speed reciprocating ring-on-block, and scratch testing

Wide loading range from mN to 12.000 N, covering nano, micro, and macro tribology

Integrated in-situ 3D optical surface measurement capability

Closed-loop servo loading control for high test stability and repeatability

Broad environmental simulation capability from cryogenic to high-temperature conditions

Modular test design with fast module replacement

Suitable for tribological studies of coatings, lubricants, material surfaces, and functional components

Fully automated XY positioning stage (130 mm × 270 mm) with 150 mm Z-axis travel

Accessories

Ball-on-disk and pin-on-disk test modules

Reciprocating ring-on-block module

Scratch and fretting test modules

Environmental chambers for temperature, humidity, pressure, and vacuum control

Interchangeable force sensors

Test Procedures

Select and install the appropriate test module according to the test method.

Mount the test specimen and counter-body securely on the test platform.

Configure test parameters including load, speed, stroke, environment, and test duration.

Perform system calibration and sensor verification before testing.

Start the test and monitor friction force, normal load, and motion signals in real time.

Conduct in-situ or post-test 3D surface profiling to analyze wear tracks.

Export and analyze test data after completion.

Maintenance Information

Regularly inspect and clean the test modules, fixtures, and sensors after testing.

Calibrate force sensors and motion systems according to laboratory quality procedures.

Keep optical components and environmental chambers clean to maintain measurement accuracy.

Ensure proper lubrication and mechanical inspection of moving components during routine maintenance.

FAQ

1. What types of tribological tests can this system perform?

The Multi-Function Friction and Wear Tester supports a wide range of tribological test modes through interchangeable modules. These include ball-on-disk and pin-on-disk rotational tests, reciprocating ring-on-block tests, fretting wear, and scratch testing. The modular design allows multiple test configurations to be performed on the same platform without structural modification, making it suitable for studying friction, wear, and surface damage across different materials and contact conditions.

2. How wide is the load range, and what applications does it cover?

The system supports a loading range from millinewtons up to 12.000 N using interchangeable force sensors. This wide range allows testing from nano-scale surface interactions to macro-scale component wear. It enables evaluation of thin coatings, micro-mechanical components, bulk materials, and heavily loaded mechanical parts under controlled and repeatable conditions.

3. Does the tester support in-situ surface analysis during testing?

Yes. The tester can be integrated with an in-situ 3D optical surface profiler capable of automatic imaging with nanometer-level resolution. Multiple optical modes, including confocal and white-light interferometry, allow real-time or post-test surface characterization of wear tracks, providing direct correlation between friction behavior and surface morphology.

4. What environmental conditions can be simulated during testing?

The system supports a wide range of environmental conditions, including temperatures from −120 °C to 1200 °C, humidity levels from 5 % to 95 % RH, pressures up to 200 psi, and high-vacuum conditions down to 10⁻⁷ torr. This makes it suitable for simulating real service environments in aerospace, automotive, and advanced materials research.

Leave Message Get Price