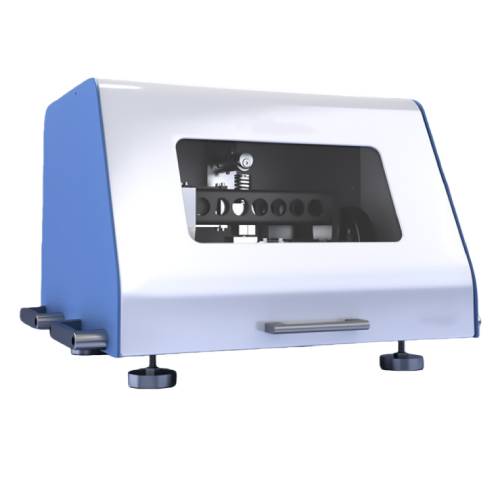

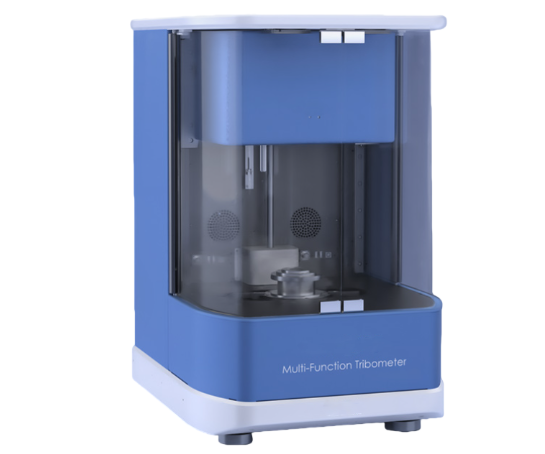

Thermal Protective Performance Tester

The Thermal Protective Performance Tester is designed to evaluate the thermal protection performance of protective clothing across industries such as textiles, petrochemical, occupational safety, and quality supervision. It provides a scientific and reliable basis for the development, quality control, and performance verification of flame-resistant protective garments.

The tester applies controlled heat flux from radiation and convection sources to protective materials or garments, measuring the thermal protective performance and generating time-temperature response data.

Applications

(1) Testing the thermal protection performance of flame-resistant protective clothing for firefighters, industrial workers, and laboratory personnel.

(2) Evaluating heat protection of safety shoes, gloves, helmets, and other personal protective equipment (PPE) surfaces.

(3) Quality control during production of thermal protective garments.

(4) Research and development of advanced flame-retardant textile materials.

(5) Verification testing in certification laboratories and compliance assessment for occupational safety standards.

(6) Performance testing under controlled radiant heat flux to determine TPP (Thermal Protective Performance) values and heat exposure response curves.

Standards

(1) NFPA 1971: Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting

(2) ASTM D4018: Standard Test Method for Continuous Filament Carbon and Graphite Fiber Bundles

(3) GB 8965.1-2009: Protective Clothing—Flame-Resistant Protective Clothing, Part 1: Flame-Resistant Garments

(4) ISO 11612: Protective Clothing—Clothing to Protect Against Heat and Flame

(5) EN 469: Protective Clothing for Firefighters—Performance Requirements for Protective Clothing

(6) ASTM F2700: Standard Test Method for Thermal Protective Performance (TPP) of Materials for Protective Clothing

Product Features

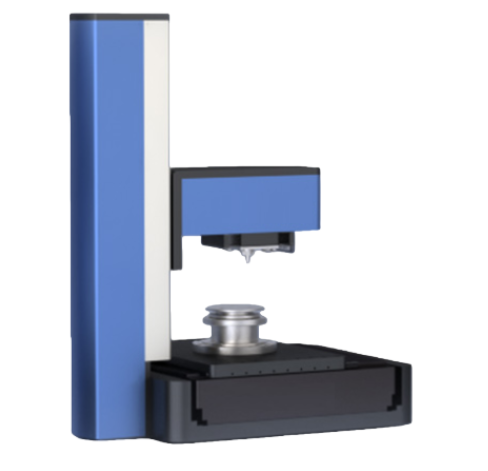

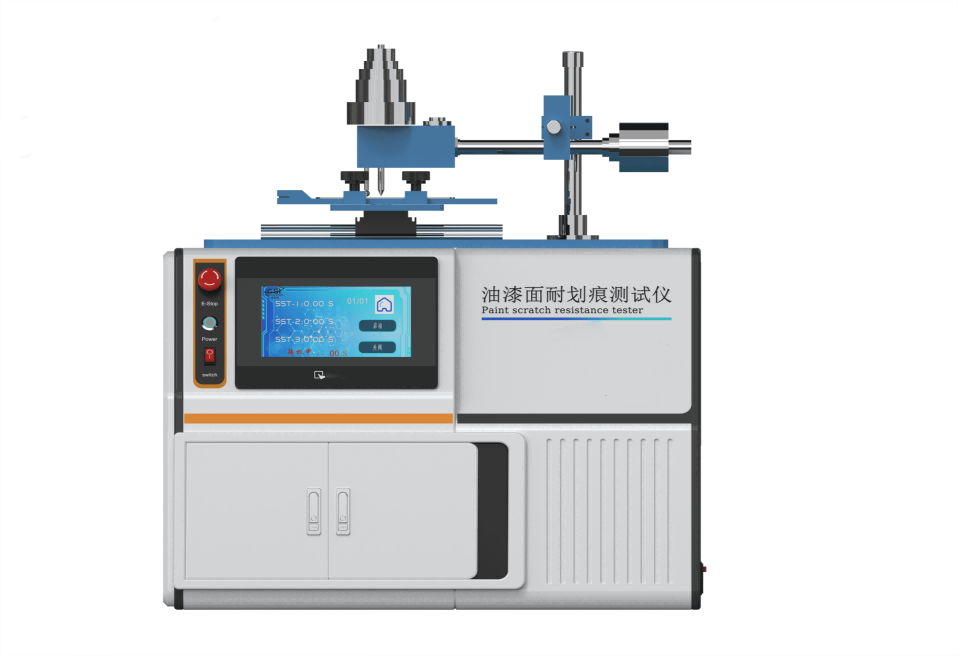

(1) Core components include sample holder assembly, radiant flame source, water-cooled shielding sensors, data acquisition system, fuel control regulator, and rotary gas flow meter.

(2) Thermal sources: one radiant heat source and two 45° convective heat sources; the radiant source consists of nine T-150 infrared quartz lamps.

(3) Movable stainless steel protective plates for flexible sample positioning.

(4) Two 45° Meker burners with adjustable airflow and combustible gas mixture.

(5) T-150 quartz lamp array providing radiant heat flux of 13 kW/m² ± 4 kW/m².

(6) Combined radiant and Meker burner heat flux adjustable up to 83 kW/m² ± 2 kW/m².

(7) Calibrated water-cooled heat flux sensor (0–100 kW/m², maximum 150%), response time <200 ms, emissivity >0.95.

(8) Real-time heat flux display and recording system.

(9) Measurement of Thermal Protective Performance (TPP) and time-temperature response curves.

(10) Traceable calibration to NIST standards.

(11) Rotameter with ±2% accuracy, flow range >3 L/min for fuel gas regulation.

(12) Pointer pressure gauge with adjustable inlet pressure via 0–15 psi regulator.

(13) Manual quarter-turn gas shut-off valve.

(14) Data acquisition system recording temperatures ≥150 °C with 0.1 °C resolution and ±0.75 °C accuracy.

(15) Automated data acquisition at ≥10 Hz with cold-junction compensation for thermocouples.

(16) Supplied computer and printer with standard testing software and preconfigured test curves.

Technical Parameters

| Parameter | Specification |

|---|---|

| Radiant Heat Source | 9× T-150 infrared quartz lamps |

| Convective Heat Source | 2× 45° Meker burners |

| Radiant Heat Flux | 13 kW/m² ± 4 kW/m² |

| Maximum Combined Heat Flux | 83 kW/m² ± 2 kW/m² |

| Heat Flux Sensor | Water-cooled, 0–100 kW/m², response <200 ms, emissivity >0.95 |

| Gas Flow Meter Accuracy | ±2%, flow >3 L/min |

| Gas Inlet Pressure Range | 0–15 psi |

| Temperature Measurement Range | ≥150 °C |

| Temperature Resolution | 0.1 °C |

| Temperature Accuracy | ±0.75 °C |

| Data Acquisition Rate | ≥10 Hz |

| Sample Holder | Stainless steel, adjustable |

| Control System | Computer + PLC + standard test software |

| Calibration | Traceable to NIST |

| Fuel Gas | Propane/Butane |

| Dimensions | Customizable per laboratory requirements |

| Weight | Dependent on configuration |

FAQ

Q1: What types of materials can be tested?

A1: Flame-resistant protective clothing, safety shoes, gloves, helmets, and other PPE surfaces.

Q2: How is heat flux applied and controlled?

A2: Heat flux is applied via nine T-150 quartz infrared lamps and two 45° Meker burners; flux is adjustable and calibrated.

Q3: Can the instrument record time-temperature response curves?

A3: Yes, the system provides real-time recording of TPP values and time-temperature curves with automated data acquisition.

Q4: Is calibration traceable?

A4: Yes, all heat flux measurements are traceable to NIST standards.

Q5: How is safety ensured during operation?

A5: Manual gas shut-off valves, pressure regulators, water-cooled sensors, and automated control systems ensure safe operation.

Leave Message Get Price