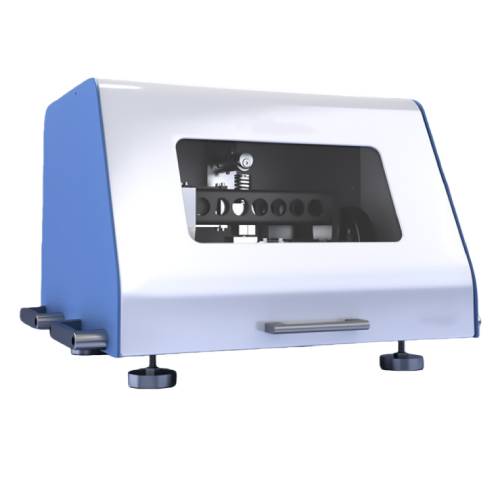

Heat Deflection and Vicat Softening Temperature Tester

The Heat Deflection and Vicat Softening Temperature Tester is designed according to GB/T 1633, GB/T 1634, and GB/T 8802 standards. It is suitable for determining the heat deflection temperature and Vicat softening temperature of non-metallic materials, polymeric materials, thermoplastics, and thermoplastic pipes and fittings.

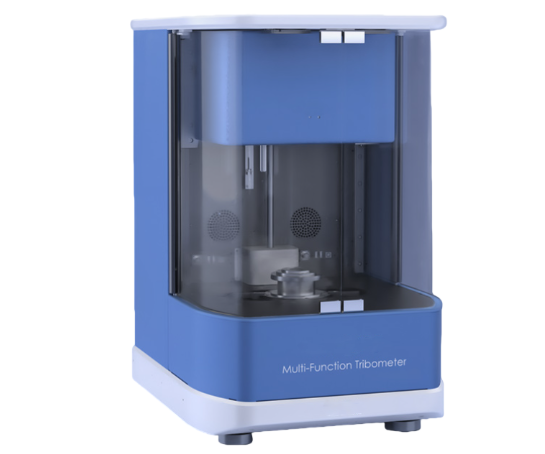

The instrument features a touchscreen control system that monitors sample deformation and test temperature in real time, dynamically plots the temperature curve, and stores historical data for report generation and comparative analysis. This facilitates high-precision, automated laboratory testing for research, quality control, and compliance verification.

Applications

(1) Determination of heat deflection and Vicat softening temperatures of thermoplastic polymers.

(2) Testing of thermoplastic pipes and fittings for mechanical and thermal performance.

(3) Evaluation of reinforced plastics, composite materials, and high-performance polymers.

(4) Quality control and R&D for polymer materials in automotive, construction, and consumer goods applications.

(5) Laboratory testing for certification, compliance, and comparison of polymeric materials under heat stress.

Standards

(1) GB/T 1634.1-2004: Plastics—Determination of Temperature of Deflection under Load, Part 1: General Test Method

(2) GB/T 1634.2-2004: Plastics—Determination of Temperature of Deflection under Load, Part 2: Plastics, Hard Rubber and Long-Fiber Reinforced Composites

(3) GB/T 1634.3-2004: Plastics—Determination of Temperature of Deflection under Load, Part 3: High-Strength Thermoset Laminates

(4) GB/T 1633-2000: Plastics—Vicat Softening Temperature

(5) GB/T 8802-2001: Thermoplastic Pipes and Fittings—Determination of Vicat Softening Temperature

(6) ISO 75: Plastics—Determination of Temperature of Deflection under Load

(7) ASTM D648: Standard Test Method for Deflection Temperature of Plastics Under Load

(8) ASTM D1525: Standard Test Method for Vicat Softening Temperature of Plastics

Product Features

(1) Aesthetic and robust cabinet with corrosion-resistant powder coating.

(2) Compact design with lockable casters for easy relocation.

(3) Stainless steel bath with high-temperature insulation for minimal heat loss.

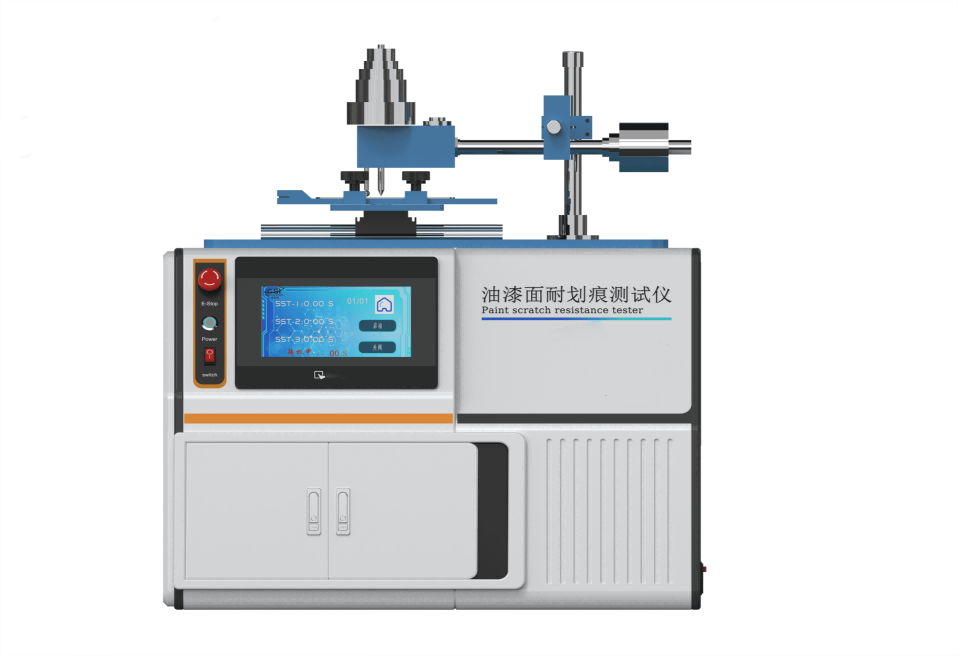

(4) Automatic lifting sample holder with motion limit protection.

(5) Dual-spiral, damping-free stirring motor for uniform bath temperature distribution.

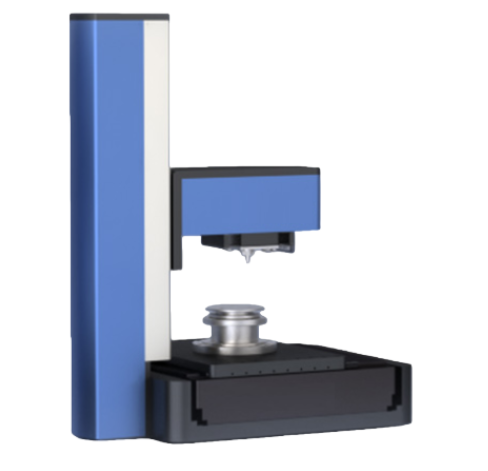

(6) High-precision, mechanically robust indenter and plunger.

(7) Fully automated operation with touchscreen and PLC control.

(8) Omron PLC ensures strong anti-interference and low failure rate.

(9) Proprietary temperature measurement technology with calibration and correction functions.

(10) Linear heating program with precise temperature ramp.

(11) High-precision electronic micrometer for deformation measurement; data automatically uploaded to touchscreen.

(12) Four high-precision temperature sensors for accurate temperature monitoring.

(13) Automatic stop and heating protection upon reaching preset deformation.

(14) Automatic data storage and report generation for historical comparisons.

Technical Parameters

| Parameter | Specification |

|---|---|

| Temperature Range | Ambient to 200 °C |

| Heating Rate | (12±1) °C/6 min or (50±5) °C/h |

| Maximum Temperature Error | ±0.5 °C |

| Deformation Measurement | Electronic micrometer, 0.001 mm resolution |

| Deformation Range | 0–12.7 mm |

| Maximum Deformation Error | ±0.001 mm |

| Sample Holder Count | 3 |

| Heating Medium | Dimethyl silicone oil, flash point >300 °C, viscosity >200 cSt, 25 L |

| Cooling Method | Natural cooling >150 °C, water or natural cooling <150 °C |

| Temperature Protection | Max 200 °C, adjustable |

| Control Mode | Touchscreen + PLC |

| Sample Holder Operation | Automatic lifting |

| Sample Support Span | 64 mm / 100 mm |

| Stirring | Dual motor, damping-free, high-speed |

| Maximum Test Load | 50 N (5000 g) |

| Power Supply | AC 220 V, 50/60 Hz |

FAQ

Q1: What types of materials can be tested?

A1: Non-metallic materials, polymeric materials, thermoplastics, and thermoplastic pipes and fittings.

Q2: How is deformation measured?

A2: Using a high-precision electronic micrometer with 0.001 mm resolution; data is automatically uploaded to the touchscreen.

Q3: How does the instrument control heating?

A3: The instrument uses a PLC and touchscreen to maintain precise heating rates and temperature, with linear heating and automatic stop when preset deformation is reached.

Q4: What is the maximum test temperature?

A4: 200 °C, with a configurable protection limit.

Q5: How is uniform temperature in the bath ensured?

A5: Dual-spiral, damping-free stirring motors provide uniform high-temperature circulation within the bath.

Leave Message Get Price