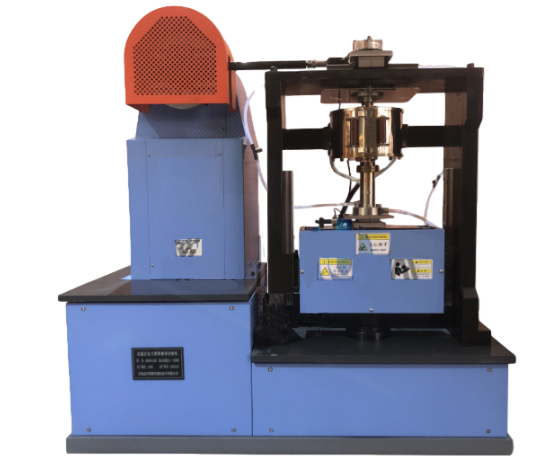

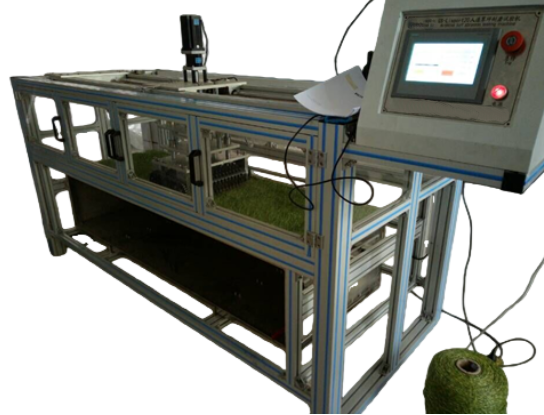

QINSUN Whole Shoe Flexing Tester (4 Stations)

A well-known footwear manufacturing company specializing in sports and casual shoes was facing an increasing number of customer complaints related to early cracking and delamination in several newly launched models. Issues such as upper–sole separation, cracking at the forefoot bending area, and outsole fatigue failure appeared during the product’s early wear cycle. These problems not only affected product reputation but also led to rising after-sales costs.

To accurately identify the root cause and verify the durability of their footwear designs, the company introduced the QINSUN Whole Shoe Flexing Tester (4 Stations). This model is engineered to simulate continuous bending movements experienced during actual walking, running, and work environments. It evaluates material fatigue, flex resistance, and cracking behavior under long-term repeated flexing.

During the testing procedure, completed shoe samples were mounted securely on the tester. The QINSUN device, equipped with a precision variable-frequency motor and high-accuracy bearings, delivered stable flexing cycles with low operation noise. Its 16.77-million-color touch screen and user-friendly interface allowed technicians to perform fully automatic one-button testing with clear parameter control. The vertical structure with four independent stations significantly improved testing throughput, enabling simultaneous evaluation of different shoe models or production batches.

Safety was also enhanced by QINSUN’s design: the machine automatically stopped once the protective cover was opened, ensuring operator protection during long-duration tests.

After multiple testing cycles in accordance with GB/T 22756, GB/T 3903.1, QB/T 1002 and other relevant standards, the engineering team obtained precise data on flex durability. The results revealed that the cracking issue originated from an outsole material batch with insufficient fatigue resistance. Meanwhile, another upgraded outsole formula demonstrated excellent performance without delamination even after extended flexing cycles. These insights allowed the company to revise material specifications, optimize the production process, and strengthen quality control.

By integrating the QINSUN Whole Shoe Flexing Tester (4 Stations) into their product evaluation workflow, the footwear manufacturer significantly reduced product failure rates, improved design validation efficiency, and enhanced overall customer satisfaction. Today, QINSUN’s testing instrument has become an essential tool in their R&D and quality inspection laboratories, supporting continuous improvement in footwear durability and performance.

Leave Message Get Price