Application Case of the G125 Pallet Incline Testing System

A leading logistics distribution company initiated a major upgrade of its pallet circulation system as part of the expansion of its regional warehouse center. The objective was to ensure safer transportation, reduce damage rates, and enhance the efficiency of daily warehouse operations. During routine handling, however, the company observed inconsistent performance among pallets from different suppliers—issues such as corner cracking, deformation under load, and cargo slippage occurred during forklift transfer, inclined-path movement, conveyor transitions, and vehicle loading and unloading. These failures posed risks to both goods integrity and operational safety.

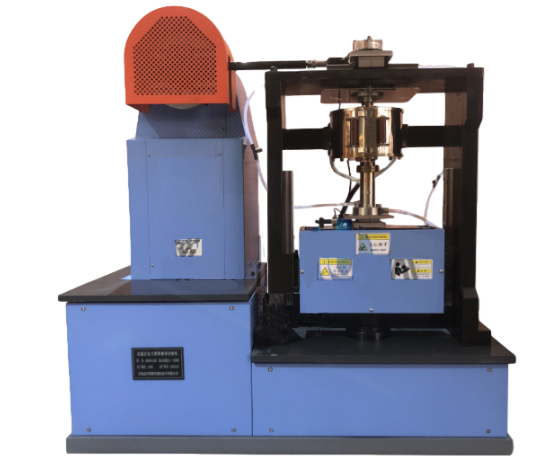

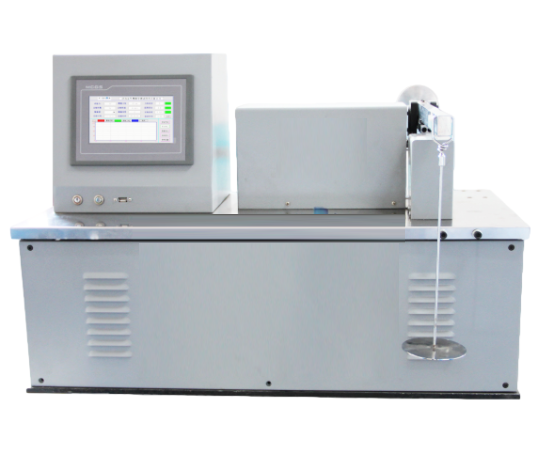

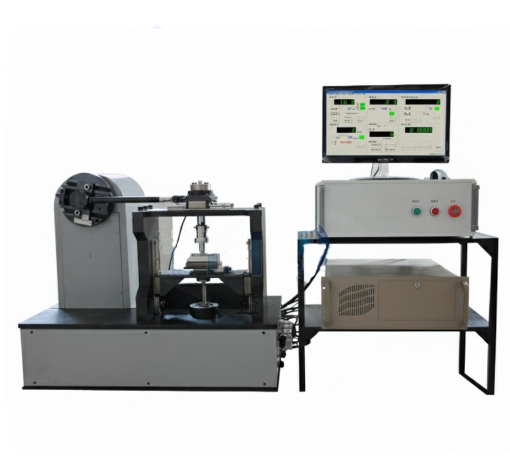

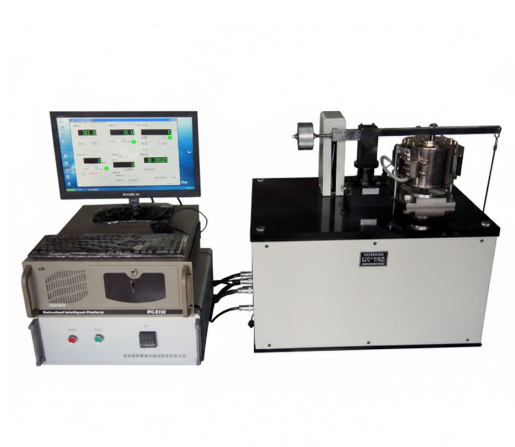

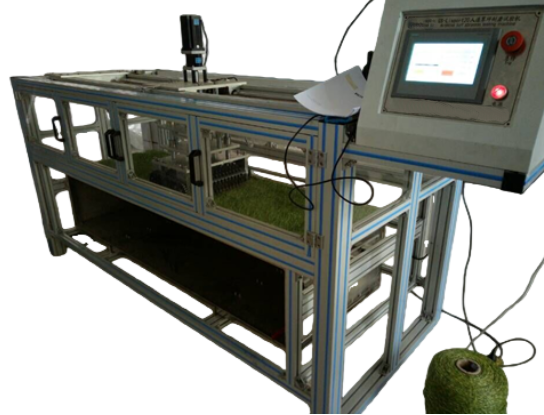

To accurately evaluate pallet durability under real-world conditions, the company adopted the QINSUN G125 Pallet Incline Testing System. As a professional testing solution developed by QINSUN, model G125 is designed to simulate a wide range of impact scenarios encountered during transport and warehouse handling. It fully complies with the requirements of ISO 2244, GB/T 4857.11, ISO 8611-1, and ISO 8611-2, ensuring that each test result reflects international standards of packaging impact performance.

During the test process, the pallet and its loaded sample were positioned on the adjustable platform of the G125. The system’s low-profile trolley design helped operators install samples with ease, while the electric positioning trolley provided precise speed control to simulate various impact intensities. The cylinder-driven incline adjustment allowed the test angle to be changed smoothly and accurately. With remote-control operation, technicians could conduct the entire test from a safe distance, preventing any risk of accidental impact.

After testing several batches of pallets, the engineering team collected essential performance data on structural integrity, impact resistance, and load stability. Some pallet models showed clear deformation when subjected to a 15° incline at specific impact speeds, indicating that they were unsuitable for high-frequency warehouse circulation. In contrast, other models maintained structural integrity and passed the impact requirements of ISO 2244 and GB/T 4857.11 when tested on the G125 system. These results allowed the company to refine its pallet procurement standards and incorporate QINSUN G125 test data as a core reference for supplier evaluation.

The application of the QINSUN G125 Pallet Incline Testing System significantly strengthened the company’s quality-control process. It improved the scientific foundation of pallet selection, minimized transportation-related losses, and enhanced overall warehouse safety. The G125 has since become a critical instrument in the company’s packaging technology laboratory and continues to support future upgrades to automated storage and logistics systems.

Leave Message Get Price