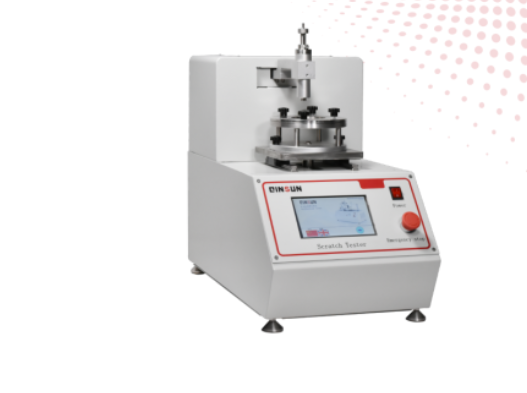

Automatic Cross-Hatch Tester | PV 3952, Ford BN 108-03,GM N 14688 Compliant

The Automatic Cross-Hatch Tester is a precision instrument designed to evaluate adhesion and scratch resistance of coatings, paints, and surface-treated materials. Widely used in automotive, aerospace, and consumer goods industries, this tester ensures reliable, repeatable results for quality control and research.

Equipped with a high-precision stepper motor and rail-guided transmission, it delivers consistent cross-hatch patterns with minimal operational noise. Modular fixtures and adjustable load systems allow testing of diverse materials with varying surface textures and specifications.

Standards Compliance

Automotive Standards

PV 3952: Plastic Interior Parts Scratch Resistance Test

Ford BN 108-03

BMW 0180

DAF KEUR 00824-401

GME 60401

GM 14829

Jaguar-Landrover TPJLR.52.004

GM N 14688

General Standards

8350Z-SDA-9000

NES M M0159

The tester supports major OEM and industry standards, ensuring global compliance for adhesion and scratch resistance testing.

Product Advantages

Unmatched Precision & Reliability: Stepper motor with rail-guided transmission ensures ±0.01mm positioning accuracy and uniform motion over long-term use.

Versatile Customization: Interchangeable weight system (5–50N, customizable to 100N) and modular fixtures adapt to diverse materials and test protocols.

Intuitive Operability: LCD touchscreen with English/Chinese interfaces simplifies setup, real-time monitoring, and pre-programmed test sequences.

Industrial-Grade Durability: Robust construction withstands high-frequency lab usage and maintains calibration for over 10,000 test cycles.

Product Features

Advanced Control System: LCD displays test progress, cutting speed, and grid spacing. Multi-language support enhances global usability.

Precision Engineering: Horizontal/vertical rail system eliminates backlash, delivering flawless cross-hatch patterns. Quick-release friction heads allow fast transitions between test configurations.

Adaptive Testing Capabilities: Flexible fixtures integrate with imported scratch heads, adjustable grid spacing (0–2mm) caters to various surface textures.

Ergonomic Design: Compact footprint (400 × 350 × 300mm) accommodates samples up to 200 × 150mm. Tool-free mounting reduces setup time significantly.

Technical Parameters

| Parameter | Details |

|---|---|

| Load Range | 5N, 10N, 20N, 50N (customizable up to 100N) |

| Cutting Speed | 10–100 mm/s (adjustable in 1mm increments) |

| Grid Spacing | 1mm, 2mm (0–2mm adjustable) |

| Sample Size | Max. 200mm (W) x 150mm (D) |

| Power Supply | 220V/50Hz, 110V/60Hz (CE-certified) |

| Dimensions | 400 (L) x 350 (W) x 300 (H) mm |

| Weight | 25 kg |

| Operating Environment | 15–35°C, ≤85% RH (non-condensing) |

Applications

Adhesion and scratch resistance testing of automotive interior plastics, coatings, and paints.

Quality control and R&D for aerospace materials and consumer goods.

Performance verification of surface-treated materials for production and OEM compliance.

FAQ

1. What materials can the Automatic Cross-Hatch Tester evaluate?

It can test coatings, paints, plastics, and other surface-treated materials in automotive, aerospace, and consumer goods applications.

2. How accurate is the cross-hatch cutting?

The rail-guided system ensures ±0.01mm positioning accuracy, critical for reproducible adhesion testing.

3. Can the load and grid spacing be adjusted?

Yes, loads range from 5–50N (customizable to 100N), and grid spacing can be set from 0–2mm to accommodate different material requirements.

4. How easy is it to operate?

The LCD touchscreen with bilingual interface allows easy parameter setup, real-time monitoring, and access to pre-programmed test sequences.

5. Is the tester durable for frequent lab use?

Yes, the robust construction and precision rail system ensure stable operation over 10,000+ test cycles with minimal maintenance.

2025-12-08 18:04