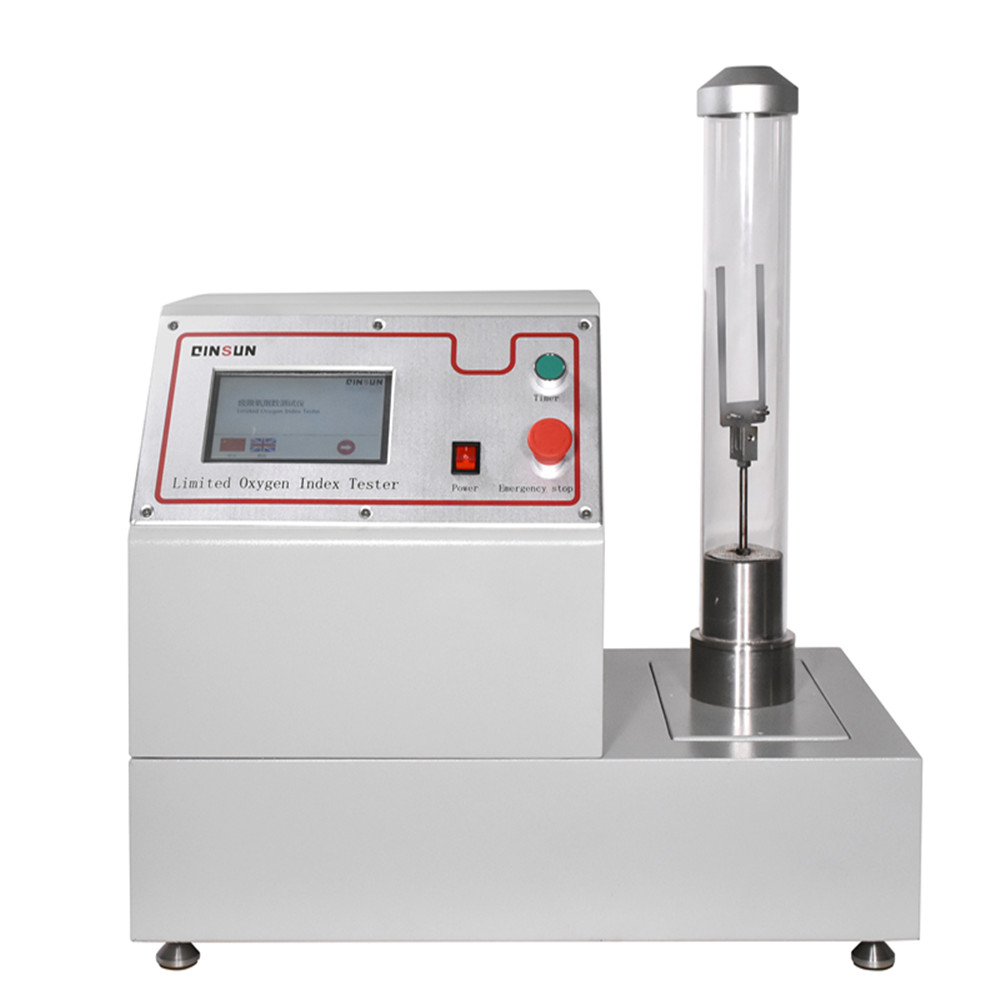

Installation and debugging of oxygen index tester

The oxygen index tester is an instrument that can be used to identify the flammability data of some polymers. It is mainly researched, developed, and produced according to GB/T2406-2009 and GB/T5454-1997.

Shanghai Qianshi Precision Electromechanical Technology Co., Ltd. was established in 2012. It focuses on the research, development, design, and production of textile testing instruments, and provides textile testing instruments and services for academic research units and testing institutions. Shanghai Qianshi is currently one of the most competitive R&D textile testing instrument manufacturers in China. The R&D team is composed of a group of experienced engineers. We are committed to serving customers wholeheartedly and striving to promote technological innovation of textile testing instruments.

It is inevitable that some problems will occur in the normal working process of the oxygen index tester, so it is particularly important to understand the oxygen index instrument in daily use, as well as its maintenance installation and inspection before and after operation.

First of all, when using the oxygen index meter, the experimental device should be checked. After opening the valve of the oxygen index meter's gas supply, we can adjust the mixed gas at will. In most cases, the flow rate is about 10L/min. When closing the inlet and outlet valves, it is necessary to record the pressure and flow rate of nitrogen, mixed gas, oxygen, and other gases. During the debugging and installation process, observe the values of each pressure gauge and flow meter after 30 minutes, and compare them with the previous recorded values. If there is no change, it means there is no leakage. If there is, it needs to be checked and maintained quickly. Usually, the temperature of the test environment needs to be controlled at 10-30 degrees Celsius and the humidity is 30%-80% in the atmosphere for testing.

Secondly, for the installation of the oxygen index meter, you can install the oxygen index meter flat on the work platform and fix it, and then use the random connecting pipes and gas source structure and other parts to connect the O2 and N2 interfaces on the back of the instrument, use the randomly configured nylon tube end to connect to the combustion tube base, and the other end to the N2+O2 interface on the back of the instrument. Pay attention to the airtightness of the interface during the process; then screw the oxygen index meter sample rack support rod into the combustion seat, and then place the randomly attached glass beads, and then put in a metal sheet to clamp it and install it on the test bracket. After we insert the glass tube into the combustion tube, the debugging and installation of the oxygen index meter are completed.

2024-11-25 11:18