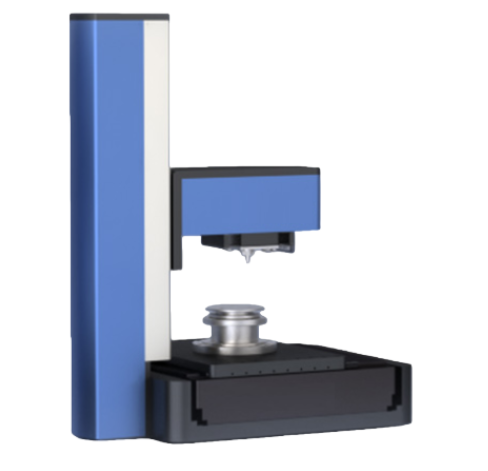

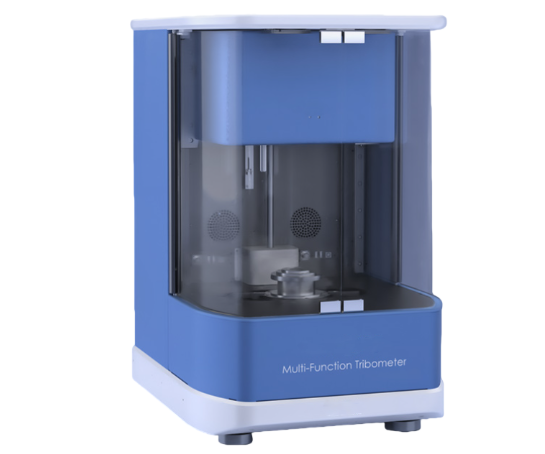

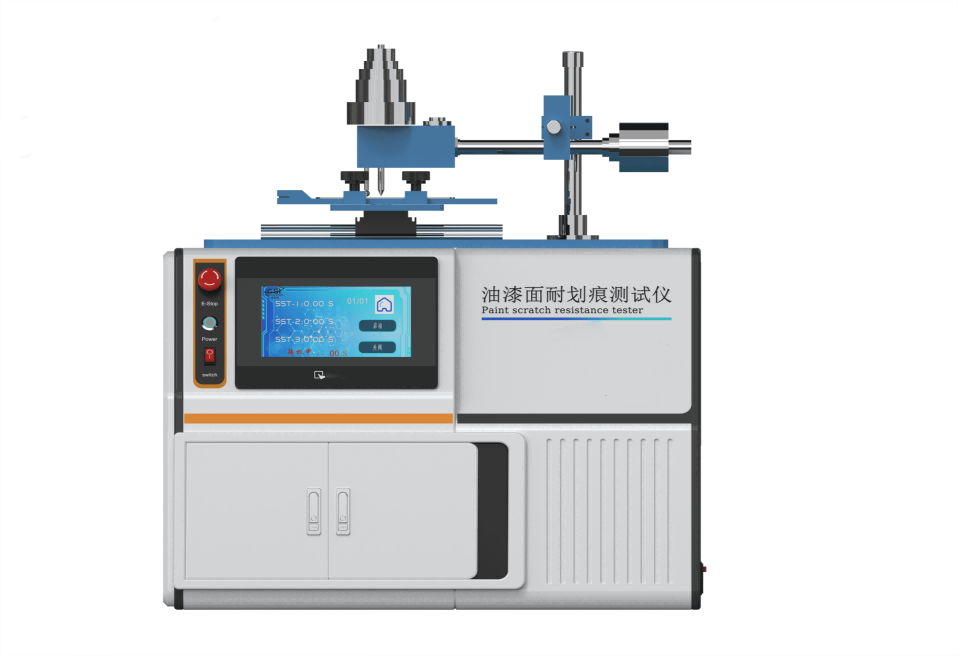

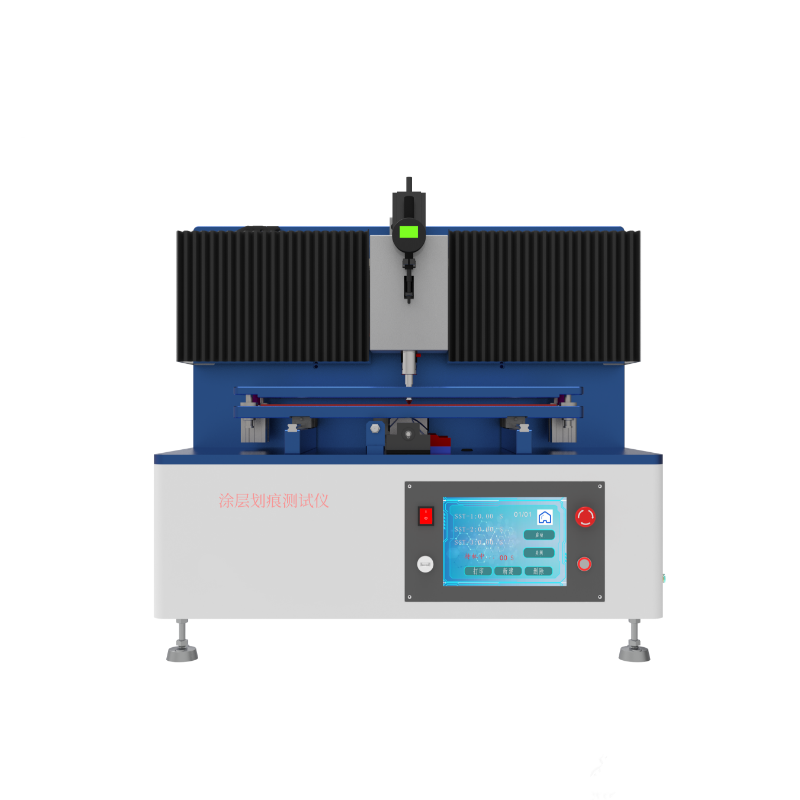

Plastic Scratch Test machine

The Plastic Scratch Test Machine is a precision testing instrument designed to evaluate the scratch resistance of plastics, films, coatings, and automotive interior and exterior decorative materials. By simulating controlled scratch conditions, it provides accurate, repeatable, and quantifiable data on surface durability, aiding in product development, quality control, and comparative performance analysis.

Application

The Plastic Scratch Test Machine is widely used for:

Assessing the scratch resistance of polymer films and plastic sheets

Evaluating coating systems and paint layers for durability

Testing automotive interior and exterior decorative materials

Quality control in R&D laboratories and manufacturing facilities

Specific testing product: Plastic Scratch Test Machine

Standards

The instrument is designed to comply with major international and national standards:

ASTM D7027‑05 – Method for evaluating scratch resistance of polymer coatings

ASTM G171 – Method for determining scratch hardness of materials

ISO 19252 – Scratch durability testing of coating systems

GB/T 23989‑2009 – Determination of scratch resistance of coatings

GB/T 1768‑2006 – Method for measuring abrasion resistance of paint films

Parameters

| Item | Details |

|---|---|

| Dimensions (approx.) | 800 × 400 × 730 mm |

| Power Supply | AC 100V, Max 60W |

| Operating Temperature & Humidity | 10–40°C / 30–70% RH, non-condensing |

| Testing Method | Increasing load method |

| Scratch Direction | Left to right |

| Detector | Force sensor |

| Vertical Load | 1–200 N |

| Horizontal Load | 200 N |

| Accuracy (Full Scale) | ±0.5% or better |

| Scratch Distance | 400 mm |

| Scratch Speed | 1 mm/sec – 400 mm/sec |

| Number of Measurements | Approx. 1000 |

Optional Configurations

Scratch tip radii: 0.5 mm, 0.75 mm, 1 mm (customizable)

Load weights: 1 N, 2 N, 5 N, 10 N, 20 N, 50 N (customizable)

Test spacing: 100–400 mm ±0.5 mm

Features

Teach Function: High-precision load region setup before sample testing.

Touch Screen Operation: Simple and intuitive control for all test functions.

Adaptable to Uneven Surfaces: Vertical load mechanism with suspension system ensures accurate testing even on irregular surfaces.

Test Condition Memory: Stores up to 20 test profiles for repeated testing.

Built-in Scratch Tips: Enables evaluation of multiple scratch types, including gloss, scale, and cut scratches.

Quantitative Scratch Evaluation: Measures scratch characteristics precisely.

Load-Dependency Assessment: Evaluates load influence in a single test.

Minimal Test Cycles: Requires few tests to assess scratch performance.

Scratch Structure Analysis: Suitable for in-depth surface analysis.

Stable Test Environment: Optimal performance at 10–40°C and 30–70% RH, non-condensing.

Accessories

Scratch tips of various radii (0.5 mm, 0.75 mm, 1 mm)

Custom load weights (1–50 N)

Touch screen controller

Sample holders

Calibration tools and cleaning kit

Test Procedures

Sample Preparation:

Select a representative sample of plastic, film, or coated material.

Inspect the surface to ensure it is free of contamination or defects that may affect the test.

Setup:

Install the sample securely in the sample holder.

Select the appropriate scratch tip and load according to the test standard.

Program scratch distance, speed, and load using the touch screen interface.

Testing Procedure

Perform scratch tests along the left-to-right direction.

Record force and scratch characteristics using the built-in force sensor.

Repeat as necessary to achieve statistically relevant results.

Use stored profiles for repeated or comparative testing.

Maintenance Information

Regularly clean scratch tips and sample holders to prevent contamination.

Verify force sensor calibration periodically to maintain accuracy.

Check vertical load and horizontal movement mechanisms for smooth operation.

Inspect electrical and control systems to ensure proper function.

FAQ

1. What is the core advantage of this product?

It provides accurate, repeatable, and quantifiable evaluation of scratch resistance for a wide range of plastics and coatings, even on uneven surfaces.

2. Are the test results reliable?

Yes. The machine uses a precision force sensor and controlled load application to ensure consistent and reproducible results.

3. Which international or industry standards does it comply with?

ASTM D7027‑05. ASTM G171. ISO 19252. GB/T 23989‑2009. GB/T 1768‑2006.

4. Why is this product important?

It allows manufacturers and R&D teams to quantitatively assess surface durability, optimize coatings, and prevent premature damage in real-world applications.

5. Which industries or applications is it suitable for?

Automotive, plastics manufacturing, film and coating R&D, quality control laboratories, and material performance analysis.

Leave Message Get Price