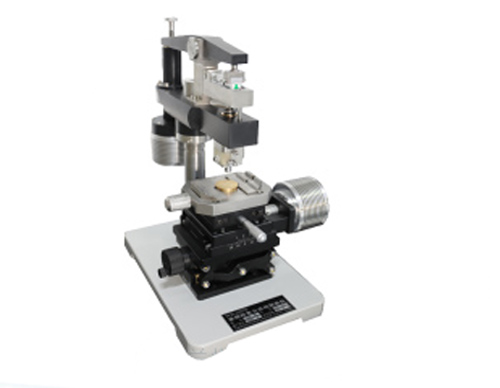

Automatic Coating Adhesion Scratch Tester

The Automatic Coating Adhesion Scratch Tester is a high-precision instrument designed for automatically evaluating the adhesion strength between surface coatings and substrates. The device integrates multiple measurement methods, including acoustic emission, friction force, static pressure, constant load, and optional electrical conductivity. It can accurately quantify the adhesion of hard or soft coatings. Since 1997, this method has been recognized as a Chinese mechanical industry standard (JB/T 8554-1997) and is widely used in coating R&D, quality control, and material performance evaluation.

Application

Coating material research and performance evaluation, including metallic, ceramic, and functional thin-film coatings.

Adhesion testing for surface treatment and protective layers, such as anodized films, sprayed coatings, and powder coatings.

Quality control and inspection in industrial manufacturing to ensure reliable bonding between coating and substrate.

Material science research to evaluate coating wear, scratch, and peel resistance under different conditions.

Standards

JB/T 8554-1997 Automatic Scratch Test for Coating Adhesion (Mechanical Industry Standard)

ISO 20502:2016 Coating Scratch Test

ASTM D7027 Coating Scratch Hardness Test

ISO 1518-1 / ISO 1518-2 Coating Hardness and Adhesion Test

DIN EN 4624 Pull-Off Test for Coating Adhesion

Parameters

| Parameter | Specification |

|---|---|

| Measurement Methods | Acoustic emission, friction force, static pressure, constant load, electrical conductivity (optional) |

| Test Load Range | 0–200 N (automatic loading), accuracy 0.3 N |

| Coating Thickness Detection Range | 0.2–150 μm |

| Standard Indenter | Diamond, cone angle 120°, tip radius R=0.2 mm |

| Sample Size | Adjustable 10–75 mm |

| Power Supply | 210–235 V, 50–60 Hz, 2000 W |

| Workbench Dimensions | 1500 × 750 × 800 mm (user-supplied) |

Features

Integrated Multi-Measurement Methods: Simultaneously supports acoustic emission, friction force, static pressure, constant load, and optional electrical conductivity.

Automatic Loading with High Accuracy: Automatic load application with 0.3 N precision ensures repeatable and stable testing.

Wide Coating Thickness Range: Suitable for coatings from 0.2 to 150 μm, covering most industrial applications.

High-Precision Indenter: Diamond tip radius 0.2 mm, cone angle 120°, guaranteeing consistent scratches and accurate measurement.

User-Friendly Operation: Adjustable sample fixture accommodates 10–75 mm samples for easy preparation and repeated testing.

Compliant with Standards: Designed according to JB/T 8554-1997 and relevant international standards.

Accessories

| Accessory | Specification / Use |

|---|---|

| Standard Diamond Indenter | Cone angle 120°, tip radius 0.2 mm, for scratch load application |

| Sample Fixture | Adjustable 10–75 mm, ensures sample stability |

| Power Cable | Input 210–235 V |

| Software & Data Acquisition Module | Automated measurement, data recording, and report generation |

| Safety Guard | Protects operators and prevents contact with moving parts |

Test Procedure

The tester applies a controlled load to create a scratch on the coating surface while monitoring acoustic emission, friction force, and indentation depth. Optional electrical conductivity measurement can further analyze coating failure. Data is captured and displayed in real-time for precise evaluation of adhesion strength.

Operation Instructions

Ensure power connection, sample fixture, and indenter installation are secure.

Select measurement method and load range according to coating thickness and type.

Keep safety guard closed; do not touch moving parts during testing.

After each test, save data and generate reports via software.

Periodically check indenter wear and replace if necessary to maintain measurement accuracy.

Experimental Flow

Install sample in adjustable fixture, ensuring flat and stable placement.

Set measurement method (acoustic emission / friction force / static pressure / constant load) and test load.

Start automatic scratch test along the predefined path.

Collect data in real-time, including acoustic emission, friction force, indentation depth, and optional conductivity changes.

Upon test completion, generate test curves and reports.

Analyze scratch patterns and force signals to evaluate coating adhesion.

FAQ

1.What is this product?

It is an Automatic Coating Adhesion Scratch Tester used to evaluate the adhesion strength of coatings.

2.What is this product used for?

To quantify coating adhesion and evaluate wear, scratch, and peel resistance.

3.Why is this product important?

Ensures coating reliability and performance in industrial applications and R&D.

4.What industries is this product suitable for?

Coating R&D, surface treatment, aerospace, automotive, and general industrial quality control.

5.What types of this product are available?

Versions with or without optional electrical conductivity measurement; all integrate multiple load measurement methods.

Leave Message Get Price