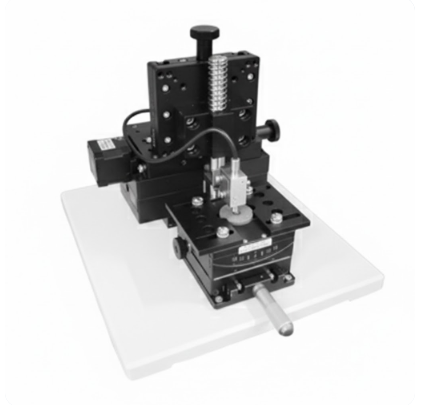

Probe-Type Material Surface Wear Scar Tester

The Probe-Type Material Surface Wear Scar Tester is a precision device designed for high-accuracy measurement of wear scars formed on material surfaces after friction and wear tests. It can automatically measure scar width and depth, calculate wear volume, and display two-dimensional profile maps for intuitive visualization of wear morphology. The instrument quantitatively evaluates material surface wear and abrasion resistance. Additionally, it can function as a step gauge to measure coating thickness and surface profiles, making it widely applicable in material research, coating evaluation, and industrial quality control.

Application

Measurement of wear scars and assessment of abrasion resistance for metals, ceramics, plastics, and composite materials.

Coating thickness measurement and surface profile analysis.

Analysis of wear scars after friction and wear experiments and collection of experimental research data.

Quality control and verification in industrial manufacturing and material inspection processes.

Standards

GB/T 3960-2016 “Test Methods for Sliding Friction and Wear of Plastics”

ISO 20502:2016 “Test Method for Coating Scratch Resistance”

ASTM D7027 “Coating Scratch Hardness and Wear Scar Measurement”

JB/T 8554-1997 “Automatic Scratch Measurement Method for Coating Adhesion” (can be used with wear scar analysis)

Parameters

| Parameter | Technical Specification |

|---|---|

| Wear Scar Scanning Mode | Automatic |

| Probe Vertical Resolution | 0.02 μm |

| Wear Volume Test Force Range | ≤40 g |

| Probe Vertical Measurement Range | ±0.5 mm (customizable) |

| X-Axis Movement Range | 0–50 mm |

| Y-Axis Movement Range | 0–25 mm |

| Z-Axis Movement Range | 0–50 mm |

| Sample Plate Size | Φ76 mm |

| Instrument Main Unit Dimensions | 230 × 300 × 260 mm |

| Instrument Main Unit Weight | 10 kg |

| Power Supply | 210–235 V, 50–60 Hz, 2500 W |

| Workbench Size | 1500 × 750 × 800 mm (user-provided) |

Features

High-precision measurement: vertical resolution of 0.02 μm ensures accurate detection of fine wear scars.

Automatic scanning and data processing: measures scar width, depth, and wear volume, generating two-dimensional profile maps.

Wide measurement range: Z-axis ±0.5 mm, X/Y axes movable to accommodate different sample sizes.

Multifunctional application: can function as a step gauge for coating thickness and surface profile measurements.

Data storage and display: real-time graphical display for research analysis and experimental data archiving.

User-friendly operation: easy sample installation, suitable for laboratory and industrial use.

Accessories and Consumables

| Accessory | Specification/Description |

|---|---|

| Automatic Scanning Probe | High-precision measurement of wear scars and profiles |

| Sample Fixing Fixture | Fits Φ76 mm sample plate, ensures measurement stability |

| Power Cable | Input 210–235 V, 50–60 Hz |

| Data Acquisition and Analysis Software | Automatically generates 2D profile maps and calculates wear volume |

| Workbench Protective Cover | Ensures safe operation and prevents measurement interference |

Test Principle

The instrument uses a probe to scan along the wear scar either transversely or longitudinally, measuring scar width and depth while recording wear volume. Minute vertical displacements of the probe are captured with high precision to form a two-dimensional wear scar profile, reflecting material surface wear. The device allows quantitative evaluation of coating or material abrasion resistance and can perform step or profile measurements, providing reliable data for material performance research.

Operation Instructions

Ensure proper connection of power, and that the probe and sample fixture are securely installed.

Select appropriate scanning parameters and measurement ranges based on scar size and depth.

Do not manually touch moving probes or samples during testing to ensure safety.

After the test, save data and generate 2D profile maps and wear volume reports via software.

Regularly inspect the probe for wear and replace as needed to maintain measurement accuracy.

Test Procedure

Sample Installation: Fix the sample onto the sample plate and adjust the fixture to ensure a flat surface.

Parameter Setting: Choose scanning mode, measurement range, and test force.

Start Scanning: The probe automatically moves along the wear scar surface, collecting depth and width data.

Data Acquisition and Display: Generate a 2D wear scar profile in real-time and calculate wear volume.

Result Saving: Save data and generate analysis reports.

Data Analysis: Evaluate material surface abrasion resistance and coating quality based on wear morphology and wear volume.

FAQ

1. What is this product?

It is a probe-based precision instrument for measuring wear scars on material surfaces, capable of quantifying wear volume and visualizing scar profiles.

2. What is this product used for?

Used to measure wear scars after friction and wear tests, evaluate coating thickness, analyze surface profiles, and support material research and industrial quality control.

3. Why is this product important?

It provides high-precision, quantitative data for assessing material and coating abrasion resistance, crucial for research, product development, and quality assurance.

4. What industries is this product suitable for?

Applicable to material science, coatings research, industrial manufacturing, quality control laboratories, and academic research institutions.

5. What types of this product are available?

Configurations include different probe types, customizable measurement ranges, and optional workbench setups for various sample sizes and testing requirements.

Leave Message Get Price