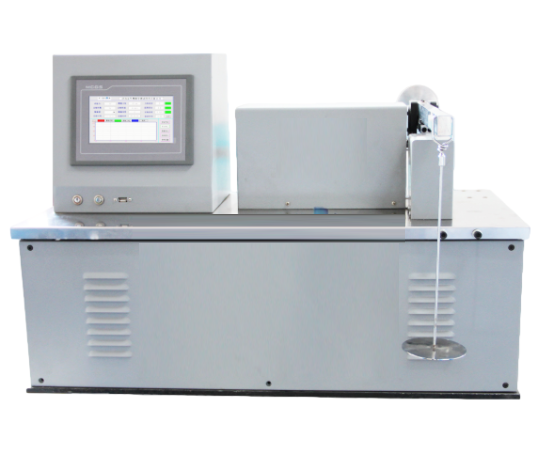

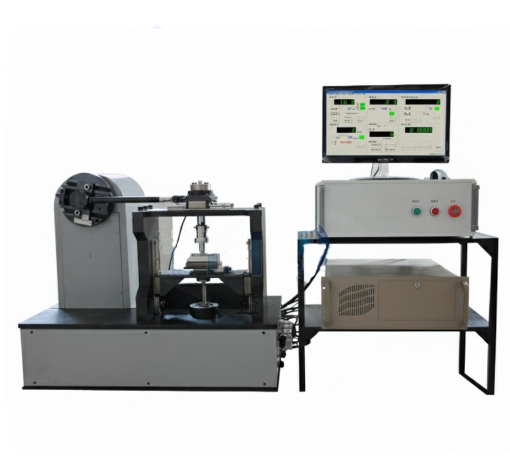

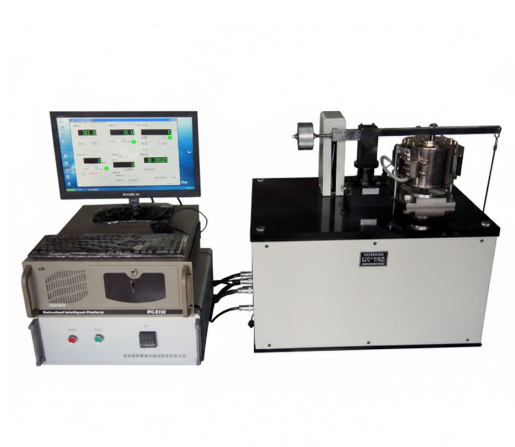

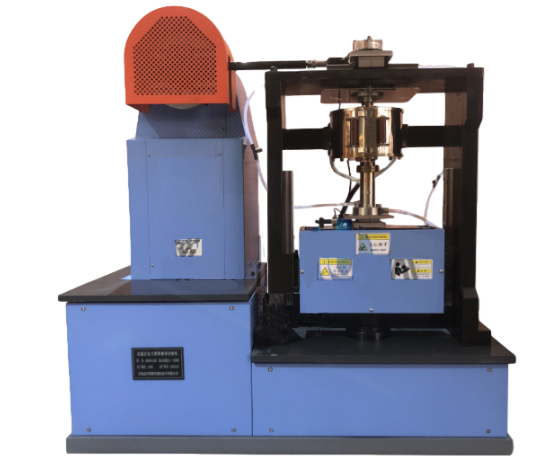

Heavy-Duty Reciprocating Friction and Wear Testing Machine

The Heavy-Duty Reciprocating Friction and Wear Testing Machine is a high-performance tribological testing instrument designed to study friction and wear behaviors of materials and surface coatings under various working conditions. The machine utilizes automatic loading and reciprocating motion, capable of testing under high load, high frequency, and high-temperature conditions. It precisely measures parameters such as friction force, coefficient of friction, and wear volume, and is widely used in material science, mechanical engineering, aerospace, metallurgy, and quality control applications.

Application

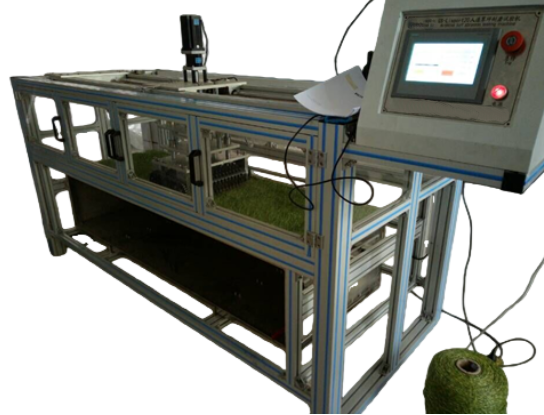

Materials testing: metals, ceramics, coatings, plastics, rubber, and other materials’ friction and wear performance evaluation.

Lubricants and oil additives testing: performance evaluation under different lubrication conditions.

Self-lubricating systems and coatings: wear resistance assessment for self-lubricating materials and coatings.

Aerospace, energy, and metallurgy industries: tribological research under extreme conditions.

Automotive industry: friction testing for engine components, braking systems, and related parts.

Comparative research: provides stable and comprehensive data under high load, high temperature, and high-frequency conditions compared with peer devices.

Standards

GB/T 3960-2016 “Test Methods for Sliding Friction and Wear of Plastics”

GB/T 14887-1993 “General Technical Requirements for Tribological Testing Equipment”

ASTM G99-17 “Standard Test Method for Wear”

ASTM G133-13 “Standard Test Method for Reciprocating Friction and Wear”

DIN 50324 “Friction and Wear Test Methods”

ISO 7148-2 “Tribology – Test Methods – Part 2: Test Procedures”

ISO 6743-8 “Lubricants – Classification”

EN 13672 “Artificial Turf Friction Performance Test Methods”

SAE J3065 “Test Method for Engine Oil Friction Characteristics”

Parameters

| Parameter | Technical Specification |

|---|---|

| Maximum Reciprocating Frequency | 10 Hz |

| Maximum Stroke | 10 mm |

| Maximum Friction Force | 1000 N |

| Maximum Load | 1500 N |

| Friction Pair Type | Block-on-Ring |

| Time Control Range | 1 s – 9999 h |

| Temperature Heating Range | Ambient – 600°C (with high-temperature furnace) |

| Loading Method | Automatic Loading |

Features

High-load capability: supports up to 1500 N test force for heavy-duty friction and wear testing.

Broad temperature adaptability: capable of testing from ambient temperature to 600°C.

Automatic loading system: ensures stable load during testing.

Real-time data acquisition and report generation: accurate, transparent, and automatic reporting.

Multiple friction pair configurations: supports block-on-ring and other friction pair types.

Flexible test condition settings: adjustable load, temperature, and frequency to simulate various real-world conditions.

Accessories and Consumables

| Accessory | Specification/Description |

|---|---|

| Heating Furnace | ±2°C accuracy, maximum 600°C |

| Friction Pair Materials | Metal, ceramic, plastic, etc. |

| Test Samples | Selected based on testing requirements |

| Loading Module | Automatic loading, adaptable to different tests |

| Control Software | Provides data acquisition and report generation |

Test Principle

The Heavy-Duty Reciprocating Friction and Wear Testing Machine simulates frictional contact under controlled test conditions. By applying various loads, speeds, temperatures, and using selected friction pair materials, the machine measures friction force, coefficient of friction, and wear volume. High-precision sensors collect real-time data to accurately reflect material performance under realistic working environments.

Operation Instructions

Device Start-up: Turn on the machine and set test parameters (load, speed, temperature, etc.).

Test Start: Begin the test; the machine will automatically load and perform reciprocating friction tests.

Real-time Monitoring: Monitor friction force, coefficient of friction, and other parameters throughout the test.

Data Saving: Upon completion, data is automatically saved and a test report is generated.

Safety Precautions: Ensure the test area is clear, avoid contact with moving parts, and follow all safety guidelines.

Test Procedure

Preparation: Install test samples and verify heating and loading modules are functioning correctly.

Parameter Setting: Configure required test parameters including load, temperature, and frequency.

Start Test: Initiate the test; the machine performs automatic reciprocating motion.

Testing Process: Collect real-time data on friction and wear parameters.

Completion and Analysis: Upon completion, the machine stops automatically, saves data, and generates a test report for analysis.

FAQ

1. What is this product?

The Heavy-Duty Reciprocating Friction and Wear Testing Machine is a high-performance tribology instrument designed to evaluate friction and wear behavior of materials and coatings under extreme working conditions.

2. What is this product used for?

It is used to measure friction force, coefficient of friction, wear volume, and related parameters for metals, ceramics, coatings, plastics, rubber, lubricants, and self-lubricating materials.

3. Why is this product important?

It provides accurate and repeatable data for material selection, product development, quality control, and ensures components meet industry standards under high-load and high-temperature conditions.

4. What industries is this product suitable for?

Widely used in aerospace, energy, metallurgy, automotive, mechanical engineering, and material science research.

5. What types of this product are available?

Configurations include standard reciprocating motion modules, high-temperature modules, and adjustable friction pairs such as block-on-ring or other specialized modules for diverse testing requirements.

Leave Message Get Price