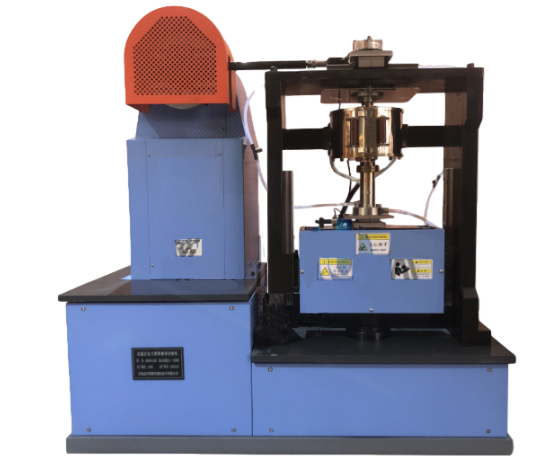

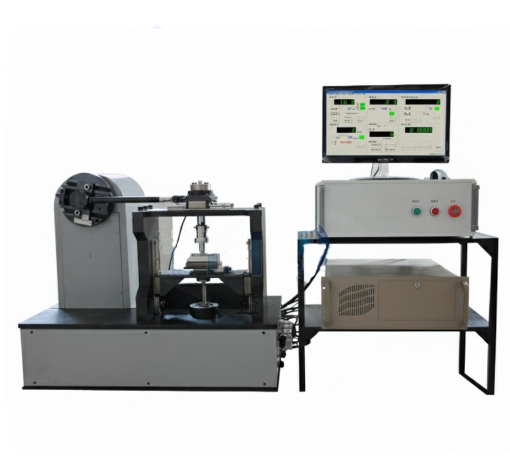

High-Speed Reciprocating Friction and Wear Tester

The High-Speed Reciprocating Friction and Wear Tester (Type 02) is designed to evaluate the friction and wear performance of materials and surface coatings. The device uses automatic loading to simulate point, line, and surface contact forms in reciprocating motion. You can test friction force, coefficient of friction, and other tribological parameters under different loads, frequencies, and temperatures. Lubricated tests are also supported. The tester is controlled via an industrial computer and dedicated software, allowing real-time monitoring, data storage, and report generation.

Applications

You can use this tester to:

Evaluate the friction and wear performance of various materials and coatings

Simulate friction under different loads, frequencies, and temperatures

Perform reciprocating friction tests with point, line, and surface contacts

Conduct tests under lubricated conditions

Support material research, product testing, and quality control

Standards

ASTM G99 – Standard Test Method for Wear Testing

ASTM G133 – High-Temperature Friction and Wear Test Method

ISO 20808 – Solid Material Friction and Wear Test

GB/T 3147 – Determination of Friction Material Wear Performance

Technical Specifications

| Parameter | Specification |

|---|---|

| Maximum Reciprocating Frequency | 20 Hz (continuously adjustable), 30 Hz (optional) |

| Maximum Stroke | 40 mm |

| Maximum Friction Force | 100 N |

| Maximum Load | 200 N |

| Friction Pair Types | Pin-on-disk, Ball-on-disk, Cylinder-on-block |

| Test Duration Control | 1 s – 9999 h |

| Lifting Height | 25 mm |

| High-Temperature Module (Optional) | Room temperature – 600℃ |

Features

High-Frequency Testing: Reciprocating frequency up to 20 Hz, supporting high-speed wear experiments

Large Stroke Range: Maximum stroke 40 mm, suitable for various friction pairs and test conditions

High-Precision Measurement: Friction force up to 100 N, load up to 200 N, ensuring accurate testing

Multiple Friction Pairs: Supports pin-on-disk, ball-on-disk, cylinder-on-block configurations

Temperature Control: Optional high-temperature module allows testing up to 600℃

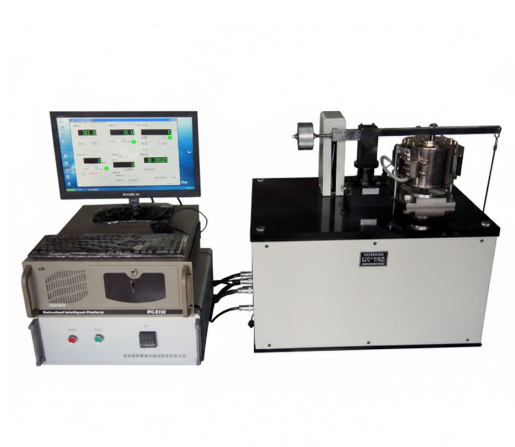

Full Automation: Controlled via industrial computer and software, with automated data recording and report generation

Safety Features: Equipped with overload shutdown and alarm functions to protect you and the equipment

Accessories & Consumables

| Name | Description |

|---|---|

| High-Temperature Module | For tests up to 600℃ |

| Friction Pair Materials | Pin-on-disk, ball-on-disk, cylinder-on-block, etc. |

| Temperature Sensors | Monitor temperature during high-temperature testing |

| Lubricants | For friction tests under lubrication conditions |

Testing Principle

This tester simulates different friction types (point, line, and surface contact) under controlled loads, frequencies, and temperatures. You can automatically control the test process while monitoring and recording friction force, coefficient of friction, and temperature in real time. The collected data allows you to analyze the tribological behavior of materials or coatings under various operating conditions.

Operation Instructions

Installation & Inspection: Ensure the tester is securely installed, power supply and control system are functioning correctly.

Sample Preparation: Select and install appropriate friction pair materials and securely fix your samples.

Parameter Setting: Use the touchscreen or computer to set load, friction pair type, test frequency, stroke, and temperature.

Start Testing: Confirm all settings and start the experiment while monitoring parameters.

Data Analysis: After testing, analyze the results with software and generate reports.

Experimental Procedure

Select Friction Pair: Choose the friction pair configuration that meets your test requirements (pin-on-disk, ball-on-disk, etc.).

Install Samples: Mount your samples securely, ensuring proper contact with the friction pair.

Set Test Parameters: Configure load, frequency, stroke, and temperature according to the test plan.

Run Test: Start the test and monitor all key parameters in real time.

Complete & Analyze: After testing, save the data, analyze the results with software, and evaluate material friction and wear performance.

FAQ

1.What is this product?

You are using a High-Speed Reciprocating Friction and Wear Tester designed to measure friction and wear performance of materials and coatings.

2.What is this product used for?

You can simulate point, line, and surface contact in reciprocating motion to evaluate friction force, coefficient of friction, and wear resistance under different loads, frequencies, and temperatures.

3.Why is this product important?

It allows you to obtain precise and reproducible tribological data, critical for material research, product development, and quality control.

4.What industries is this product suitable for?

You can use it in materials science, coatings, polymers, ceramics, lubrication studies, and industrial testing laboratories.

5.What types of this product are available?

You can configure it with optional high-temperature modules (up to 600℃), different friction pair types, and lubrication testing capabilities.

Leave Message Get Price