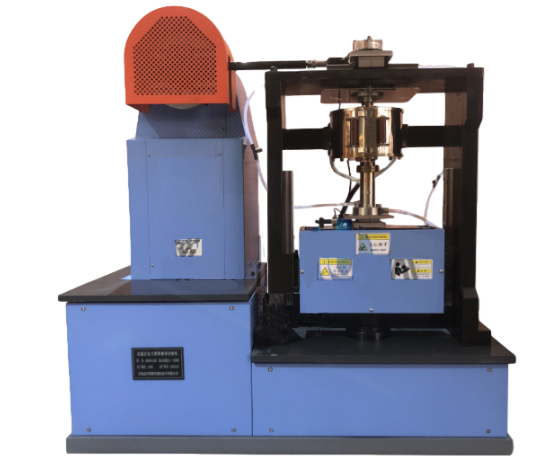

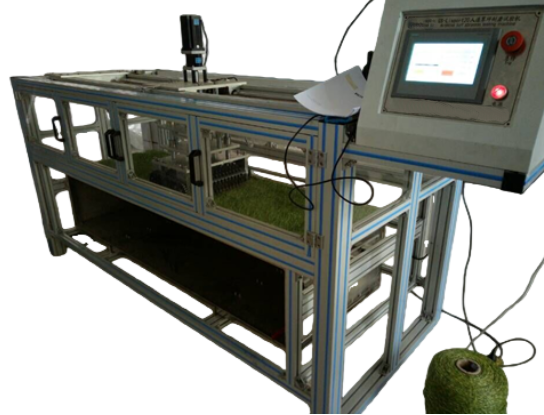

Reciprocating-Rotary Friction and Wear Tester

The Reciprocating-Rotary Friction and Wear Tester (Type 1) is designed for evaluating the tribological performance of materials and surface coatings. This device simulates rotational and linear reciprocating motion under a controlled test force. By adjusting parameters such as load, speed, frequency, stroke, duration, friction pair materials, surface roughness, and hardness, you can assess the comprehensive performance of materials or coatings. The system provides real-time monitoring of friction force, test load, and temperature, and dynamically plots all key parameters. Safety functions include automatic shutdown or alarms if preset limits are exceeded.

Applications

You can use this tester to:

Evaluate the tribological performance of material surfaces and coatings

Test wear resistance and friction coefficients of friction pairs, including metals, polymers, and ceramics

Monitor friction force, temperature, and other parameters in real time

Support material research, quality control, and production testing

Standards

ASTM G99 – Standard Test Method for Wear Testing

ASTM G133 – High-Temperature Friction and Wear Test Method

ISO 20808 – Solid Material Friction and Wear Test

GB/T 3147 – Determination of Friction Material Wear Performance

Technical Specifications

| Parameter | Range / Specification |

|---|---|

| Maximum Test Force | 1000 N |

| Maximum Speed | 2000 rpm |

| Maximum Frequency | 200 Hz |

| Maximum Reciprocating Friction Force | 100 N |

| Maximum Rotational Torque | 4.7 Nm |

| Reciprocating Stroke Range | ±6 mm |

| Reciprocating Friction Modes | Ball-on-disk, Pin-on-disk, Cylinder-on-disk |

| Rotational Friction Modes | Ball-on-disk, Pin-on-disk, End-face |

| Temperature Range | Room temperature – 600℃ |

| Notes | Optional micro-force module, ring-block module available |

Features

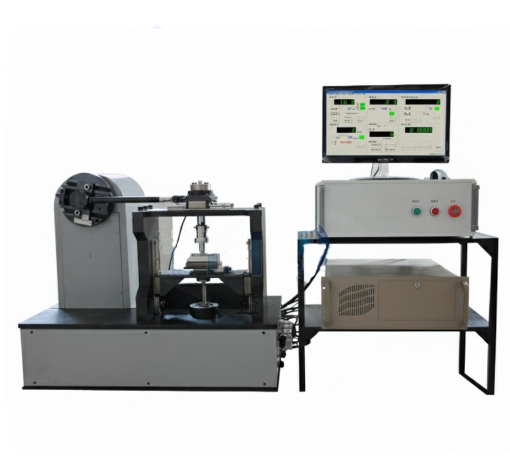

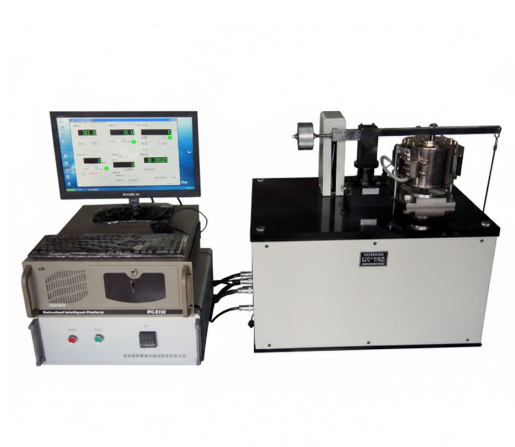

Dual Friction Modes: Supports both rotational and reciprocating friction, with multiple friction configurations (ball-on-disk, pin-on-disk, etc.)

High-Precision Force Control: Maximum test force up to 1000 N, suitable for high-load testing

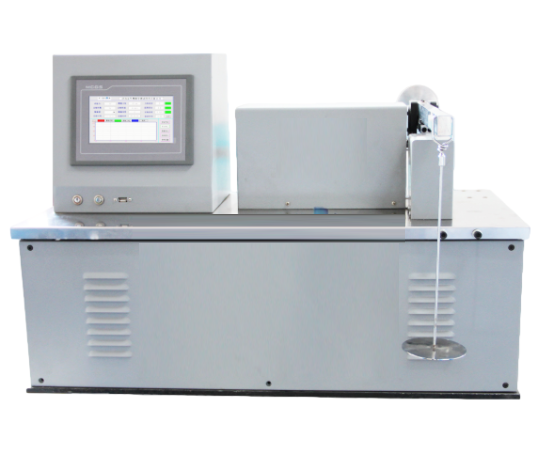

Wide Temperature Range: Capable of testing from room temperature up to 600℃

High-Speed & High-Frequency Testing: Up to 2000 rpm and 200 Hz for precise and efficient testing

Real-Time Monitoring: Friction force, test load, and temperature are continuously monitored and plotted

Multiple Friction Pairs: Supports various materials and modules, including micro-force and ring-block options

Safety Protection: Automatic shutdown or alarm if preset limits are exceeded

Accessories & Consumables

| Name | Description |

|---|---|

| Micro-Force Module | Enables low-load tests with enhanced precision |

| Ring-Block Module | Provides additional friction pair configurations |

| High-Temperature Furnace | For friction testing at elevated temperatures |

| Temperature Sensors | Monitor friction pair temperature during high-temperature testing |

| Friction Pair Materials | Ball-on-disk, pin-on-disk, cylinder-on-disk, end-face, etc. |

Testing Principle

This tester evaluates the tribological behavior of materials under rotational and reciprocating motion. By applying controlled forces and adjusting parameters such as speed, frequency, stroke, and temperature, you can measure friction force, wear, and temperature changes. Real-time monitoring allows comprehensive assessment of wear resistance, friction coefficient, and surface thermal behavior under varying operating conditions.

Operation Instructions

Installation & Inspection: Ensure all connections are secure, power supply is stable, and the control system is functioning correctly.

Sample Preparation: Prepare friction pair materials and securely fix the samples in place.

Parameter Setting: Use the touchscreen to set test force, rotational speed, frequency, stroke, temperature, and friction pair type.

Start Testing: Confirm settings and start the experiment while monitoring the parameters in real time.

Data Recording & Analysis: After the test, save the data and analyze friction and wear performance using dedicated software.

Experimental Procedure

Select Friction Pair & Parameters: Choose friction pair materials and configure test parameters such as load, frequency, stroke, and temperature.

Prepare Samples: Fix the samples in the testing position, ensuring good contact with the friction pair.

Conduct Testing: Start the experiment, monitoring friction force, temperature, and other parameters in real time.

End Testing & Data Processing: Record the results and use software to analyze wear, friction coefficient, and generate a complete test report.

FAQ

1.What is this product?

You are using a Reciprocating-Rotary Friction and Wear Tester, designed to evaluate material and coating tribological performance.

2.What is this product used for?

You can simulate rotational and reciprocating friction to assess wear resistance, friction coefficients, and temperature behavior under controlled conditions.

3.Why is this product important?

It provides you with reliable, real-time data on material performance, helping in research, quality control, and product development.

4.What industries is this product suitable for?

You can use it in material science, coatings, polymer research, ceramic development, tribology labs, and industrial quality control.

5.What types of this product are available?

You can configure it with different friction pairs, micro-force modules, ring-block modules, and optional high-temperature testing up to 600℃.

Leave Message Get Price