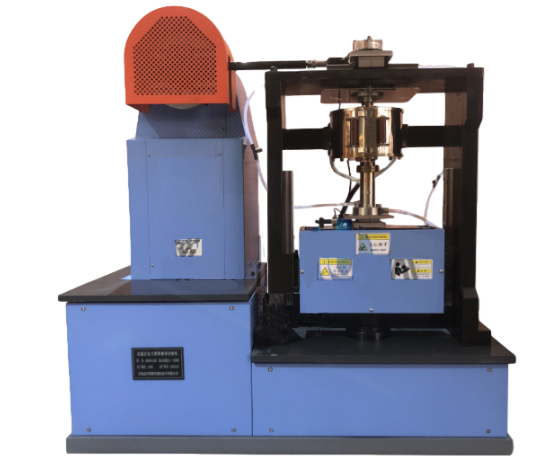

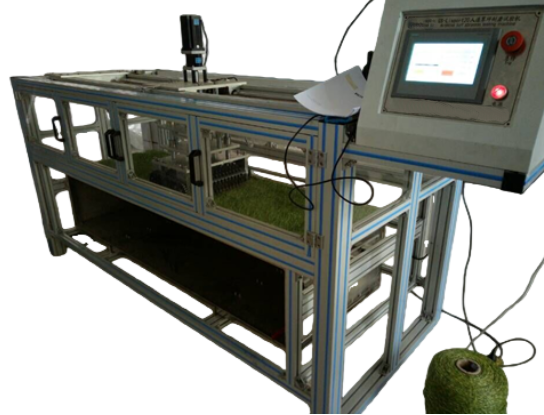

Gravel Flame Jet Test Apparatus

The Gravel Flame Jet Test Apparatus is designed to evaluate battery enclosure materials under simulated thermal runaway conditions. You can use this instrument to test sheet materials rather than entire battery assemblies, allowing you to efficiently assess material performance while reducing development costs and time. It provides precise control over flame and particle exposure, helping you determine the thermal and mechanical resilience of battery housing materials.

Application

You can use the apparatus in the following scenarios:

Battery housing material evaluation: Assess thermal and mechanical performance of sheet materials under simulated battery thermal runaway conditions.

Coating and surface protection testing: Determine material resistance to flame and particle impact.

Research and development: Optimize battery safety designs and reduce prototype testing costs.

Quality control laboratories: Routine evaluation of materials for compliance with flame and impact resistance standards.

Compatible test components: Flame jet burner, particle injection system, stainless steel sample racks, temperature measurement system.

Standards

This test apparatus conforms to a wide range of international standards:

UL 2596 Ed. 2 — Test methods for thermal and mechanical performance of battery enclosure materials

ASTM D3170 — Test method for coating and material gravel impact resistance

SAE J400 — Automotive surface coating gravel impact standard

ISO 20567‑1 — Paint and varnish coating gravel impact resistance, Part 1

DIN 55996‑1:2001 — Coating material gravel impact strength, Part 1

ISO 22899‑1 — Passive fire protection materials, flame jet performance test, Part 1

EN 60695‑11‑20 — Fire testing methods

ISO 3795 — Determination of burning behavior of materials used in road vehicle interiors

UL Torch and Grit (TaG) Test — Flame and particle medium test

Parameters

| Parameter | Specification |

|---|---|

| Dimensions | 1600 × 750 × 2100 mm |

| Weight | 250 kg |

| Flame Jet Diameter | 28.6 mm |

| Methane Supply Ports | 30 |

| Oxygen Supply Ports | 78 |

| Flame Output | 3 kW (flame), 1.5 g/s (particle flame) |

| Ignition | Electric spark ignition |

| Methane Flow Controller | 0–10 L/min, accuracy ±2% F.S |

| Oxygen Flow Controller | 0–50 L/min, accuracy ±2% F.S |

| Temperature Measurement | 4-channel K-type thermocouples (30 AWG) |

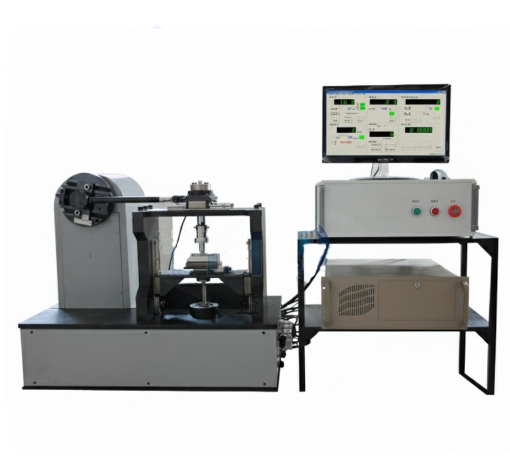

| Sample Rack | Stainless steel, calibration and test positions, automatic insertion |

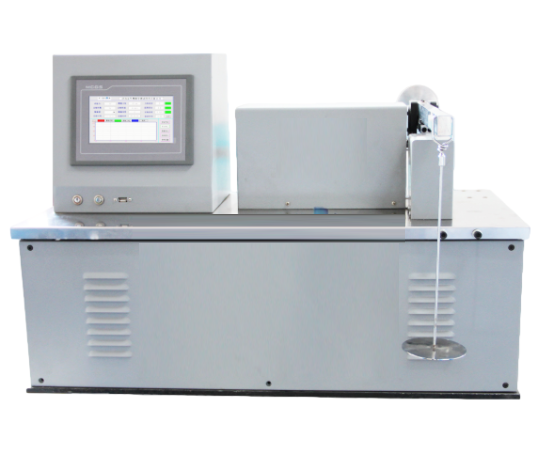

| Control System | Integrated control box with manual/automatic operation and data acquisition |

| Software | Windows-based, supports temperature calibration, manual/automatic programs, data logging, and report export |

Features

Integrated steel structure: Open test platform reduces heat accumulation.

Smoke collection: Stainless steel hood with adjustable exhaust airflow for efficient fume removal.

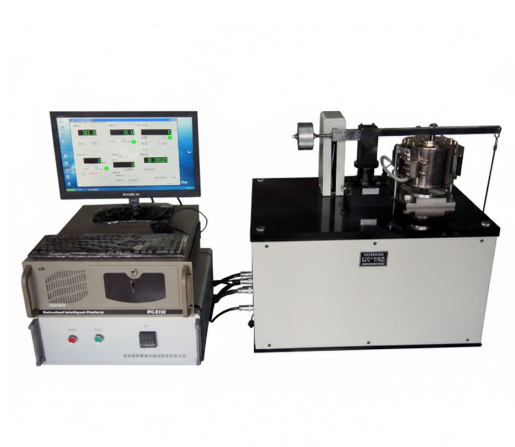

Imported flame burner: Compatible with UL laboratory standards, provides both flame jet and particle flame.

Precise flow control: Mass flow controllers for methane, oxygen, and air with temperature and pressure compensation.

Automated operation: Flame application and particle flame control with electric spark ignition.

Advanced temperature monitoring: Four thermocouples measure flame and sample temperatures at multiple points.

Flexible sample positioning: Calibration and test positions with automatic sample insertion.

User-friendly software: Manual and automatic modes, temperature calibration, time-temperature and particle-time curve generation, and report output.

Accessories

Flame jet burner with particle injection system

Stainless steel sample racks (calibration and test positions)

Smoke collection hood with adjustable airflow

Temperature measurement thermocouples and mounting accessories

Control box with integrated software and data acquisition system

Test Procedures

Install the test sample on the stainless steel sample rack in the designated test position.

Connect the methane, oxygen, and compressed air supplies.

Activate the flame jet burner and particle injection system according to the software control.

Record flame exposure and particle impact parameters using the thermocouples and data acquisition system.

Analyze the material’s thermal and mechanical performance based on temperature, time, and particle exposure data.

Export and review test reports using the integrated software.

Maintenance Information

Clean the flame burner and particle supply ports regularly to ensure consistent flame quality.

Check and calibrate mass flow controllers for methane, oxygen, and air periodically to maintain accuracy.

Inspect sample racks and thermocouples before each test to prevent mechanical deformation or sensor errors.

Keep the control box and software updated and ensure proper ventilation around the exhaust system.

FAQ

1. What is this product?

It is a specialized apparatus for evaluating battery enclosure materials under simulated thermal runaway conditions using flame and particle exposure.

2. What is it used for?

You can use it to test sheet materials for thermal and mechanical performance, optimize battery safety designs, and reduce R&D costs.

3. How does it work?

Flames and particles are applied to the material surface using a controlled burner and injection system, while thermocouples record temperature and exposure time. Data is collected and analyzed to evaluate material performance.

4. Why is it important?

This instrument allows you to identify materials that can withstand thermal runaway and particle impact, improving battery safety and compliance with international standards.

5. Which industries is it suitable for?

Battery manufacturing, electric vehicle R&D, energy storage systems, material development labs, and any industry requiring fire and impact performance certification for enclosure materials.

Leave Message Get Price