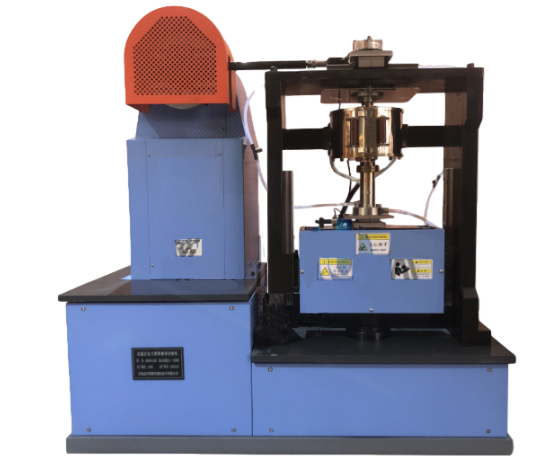

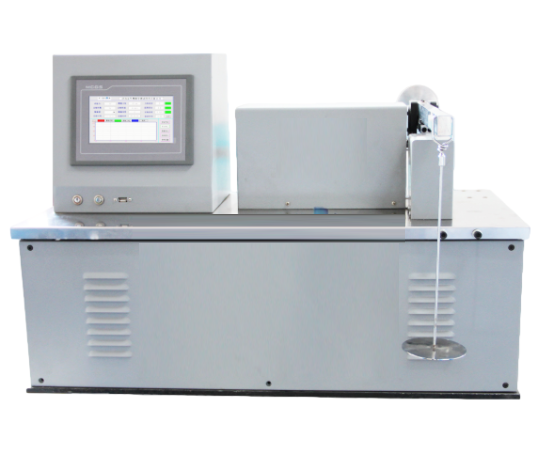

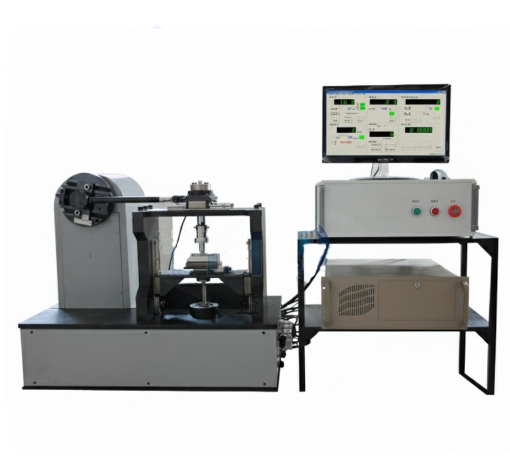

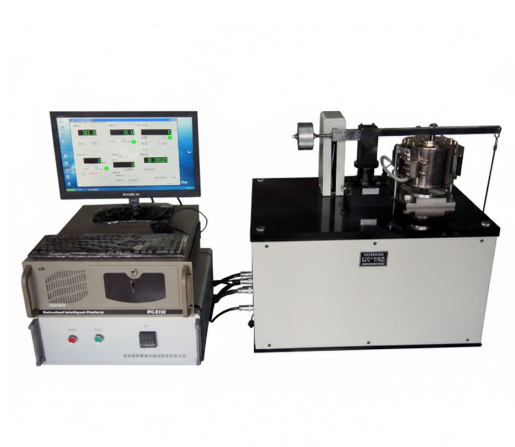

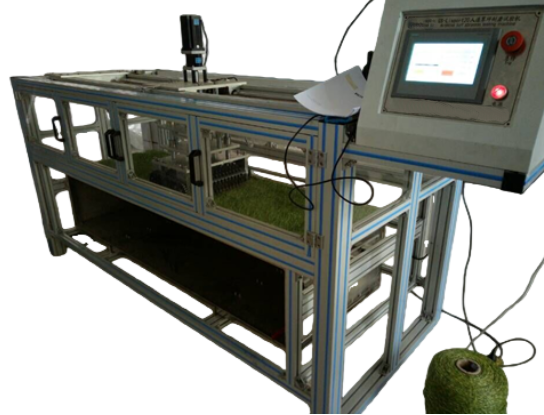

Flame Spread Tester for Thermal and Acoustic Insulation Materials

The Flame Spread Tester for Thermal and Acoustic Insulation Materials is designed to evaluate the flame propagation characteristics of insulation and acoustic materials. You can expose samples to a standard thermal radiation source and ignite them with a controlled flame to determine their critical heat flux. This instrument is FAA-approved and compliant with international standards, providing accurate and repeatable measurements for aerospace, civil aviation, and material development applications.

Application

You can apply this tester in the following scenarios:

Aerospace material testing: Evaluate flame propagation of thermal and acoustic insulation materials in aircraft interiors.

Civil aviation compliance: Test materials in accordance with FAA FAR Part 25 Appendix F Part VI.

Material development: Assess thermal and acoustic insulation performance during R&D.

Quality control: Monitor flame spread properties in production lines to ensure safety compliance.

Compatible test standards and protocols: FAR Part 25 Appendix F Part VI, Airbus AITM 2.0053. Boeing BSS 7365. MH/T 6042‑2006. and relevant national standards.

Standards

This tester conforms to the following national and international standards:

GB/T 27904‑2011 — Test method for flame spread of interior decoration materials

GB/T 25207‑2010 — Classification of combustion performance of building decorative materials

GB 8624‑2012 — Classification of burning behavior of building materials and products

GB/T 16172‑2007 — Determination of heat release rate and total heat release of building materials and products (Cone Calorimeter Method)

BSS 7365 — UK aerospace standard for combustion and smoke density of aerospace composite and interior materials

AITM 2.0053 — European aerospace industry method for heat release rate and smoke evaluation

FAR Part 25 Appendix F Part VI — FAA regulatory requirement for flame propagation, smoke density, and toxicity in civil aircraft cabin materials

Parameters

| Parameter | Specification |

|---|---|

| Dimensions | 1220 × 570 × 520 mm; 1200 × 1150 × 1350 mm; 800 × 800 × 400 mm |

| Weight | 185 kg |

| Thermal Radiation Source | 400 VAC, 3-phase electric heating plate, PID control, ±0.1°C accuracy |

| Radiation Strip Width | 76 mm, six strips, operational up to 704°C |

| Sample Angle | 30° relative to horizontal plane |

| Ignition System | Axially symmetric propane burner, 0.15 mm nozzle |

| Burner Height | Flame at least 51 mm above sample plane |

| Flame Spread Measurement | Laser pointer for accurate monitoring |

| Thermocouple Placement | Back wall 279 mm, right wall 292 mm, below radiation plate 51 mm, ±2°C accuracy |

| Heat Flux Range | ≥60 kW/m², with self-circulating cooling water |

| Heat Flux Mounting | Steel plate 3.2 mm thick, with 3 × 25.4 mm insertion holes |

| Sample Holders | Standard and short versions (for hook-and-loop tests) |

| Data Acquisition | Computer and printer, automatic test timing ±0.1 s |

Features

Enclosed test chamber: Includes integrated chimney and controlled radiation environment.

Precision thermal radiation source: PID-controlled electric heating plate ensures uniform, stable heat flux.

Automated sample handling: Pneumatic sliding drawer allows easy sample insertion and removal.

Accurate ignition and flame monitoring: Propane burner with laser pointer ensures precise flame spread measurement.

Thermocouple monitoring: Accurately records sample and chamber temperatures at multiple points.

High-performance heat flux system: Measures critical heat flux for ignition and flame propagation.

Data acquisition and automation: Test time, flame spread, and other parameters are recorded automatically and with high precision.

Safety and repeatability: Controlled combustion and automated monitoring ensure consistent and safe testing conditions.

Accessories

Enclosed radiation test chamber with integrated chimney

3-phase electric heating plate with PID temperature control

Pneumatic sliding drawer for sample insertion and removal

Propane burner with 0.15 mm nozzle

Laser pointer for flame spread measurement

Thermocouples and mounting accessories

Water-cooled heat flux measurement system

Standard and short sample holders

Computer and printer with data acquisition system

Test Procedures

Install the sample in the test chamber using the pneumatic drawer and proper sample holder.

Connect the propane supply and compressed air system.

Activate the radiation source to achieve the desired thermal flux and preheat the sample.

Ignite the sample using the propane burner positioned 51 mm above the sample plane.

Monitor flame spread using the laser pointer and record temperature, heat flux, and ignition parameters via the data acquisition system.

Test duration is automatically recorded and ends at the set time or upon completion of flame propagation.

After testing, remove the sample and inspect the chamber for maintenance and cleaning.

FAQ

1. What is this product?

It is a flame spread tester specifically designed for thermal and acoustic insulation materials, allowing you to measure critical heat flux and flame propagation.

2. What is it used for?

You can use it to evaluate flame spread, ignition characteristics, and thermal performance of insulation materials, particularly for aerospace and civil aviation applications.

3. How does it work?

A controlled thermal radiation source heats the sample, which is ignited using a propane burner. Thermocouples, laser monitoring, and data acquisition record flame spread, temperature, and heat flux.

4. Why is it important?

This instrument ensures that thermal and acoustic insulation materials meet aviation and fire safety standards, providing reliable, repeatable, and safe testing conditions.

5. Which industries is it suitable for?

Aerospace, civil aviation, insulation material development, fire safety research, and quality control laboratories.

Leave Message Get Price