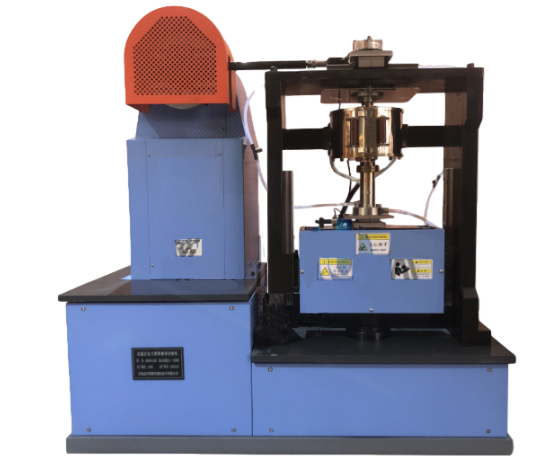

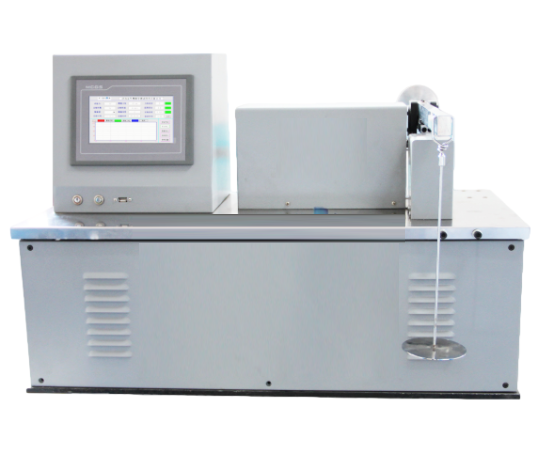

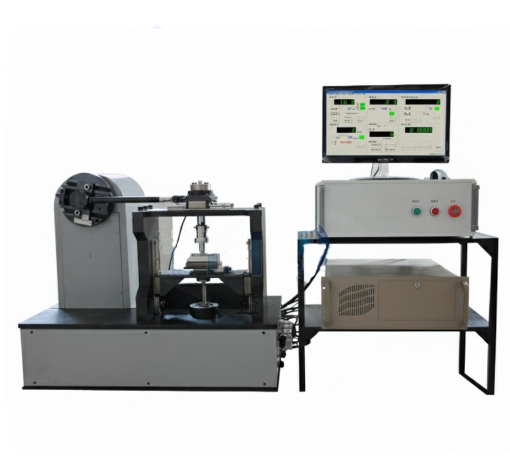

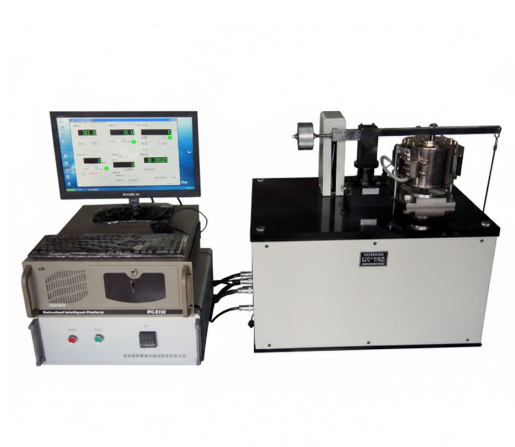

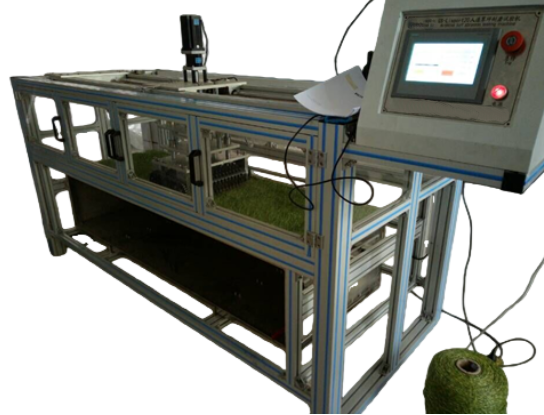

Surface Flame Spread Test Apparatus

The Surface Flame Spread Test Apparatus is a high-precision instrument designed for evaluating the lateral flame propagation of materials. It is primarily used in compliance with BS 6853 series railway fire safety standards and BS 476-7 for building materials. This apparatus enables you to determine flame spread ratings based on flame extension length and propagation speed. With an advanced water-cooled sample holder, calibrated radiation panel, and digital flux sensors, you can perform controlled laboratory tests on wall, ceiling, and surface materials to ensure compliance with international fire safety regulations.

Application

The Surface Flame Spread Test Apparatus is suitable for a wide range of applications:

Building Materials Testing: Evaluate flame spread on wall and ceiling surfaces according to BS 476-7.

Railway Vehicle Materials: Conduct fire resistance and smoke toxicity evaluations in accordance with BS 6853.

Interior Materials: Assess flame spread for plastics, composites, and surface coatings using ISO 5658-1/2 and ASTM E162 standards.

Laboratory Research: Determine critical heat flux, lateral flame extension, and flame propagation characteristics under controlled conditions.

Recommended test products include wall panels, ceiling boards, interior panels, decorative laminates, plastics, and other surface materials used in public or transport environments.

Standards

The apparatus supports compliance with the following international standards:

GB/T 8624‑2012 – Classification of combustion performance of building materials

GB/T 27904‑2011 – Flame spread performance test methods for interior decoration materials

GB/T 2406.2‑2009 – Plastics burning performance test, vertical burning method

GB/T 2408‑2008 – Plastics burning performance test, horizontal burning method

ISO 5658‑1 – Fire spread index of building materials, small flame spread test, Part 1

ISO 5658‑2 – Fire spread index of building materials, small flame spread test, Part 2

ISO 5660‑2 – Heat release rate, smoke production, and mass loss, Part 2: Flame spread test method

ISO 5660‑4 – Heat release rate, smoke production, and mass loss, Part 4: Automotive interior materials

ASTM E162 – Surface flammability characteristics of materials (Flame Spread Index, FSI)

ASTM E648 – Assessment of carpet material flame spread

UL 94 – Plastic material flammability testing (Vertical and Horizontal Burning)

BS 476‑6:1989 + A1:2009 – Fire tests on building materials, Part 6: Small flame spread test

BS 6853:1999 – Railway vehicle material flame spread, smoke density, and toxicity evaluation

Parameters

| Parameter Category | Details |

|---|---|

| Dimensions | 1760 × 1450 × 2130 mm |

| Weight | 678 kg |

| Radiation Panel | 850 × 850 mm |

| Power Supply | 220V, 50Hz, 10A |

| Operating Temp | 10°C – 35°C |

| Gas Requirements | Industrial propane, compressed air |

Features

Large Radiation Panel: 850 × 850 mm with reinforced structural support.

Vertical Sample Holder: Includes standard scale markings to measure flame spread distance and critical heat flux.

Water-Cooled System: Prevents sample holder damage during long-duration high-temperature testing.

Small Flame Ignition: Uses electric spark ignition for consistent flame application.

Automatic Safety Cut-Off: High-temperature sensors shut off gas supply if the radiation panel extinguishes.

Calibrated Heat Flux Sensors: Traceable to NIST for accurate radiation flux measurement.

Digital Control Box: Allows adjustment of gas and air flow with digital display of radiation flux.

PLC & HMI Integration: Displays all test parameters for real-time monitoring and control.

Accessories

Water-cooled sample holder

Calibrated porous panel

Heat flux sensors

Electric spark ignition system

PLC & HMI control system

Gas and air flow regulation valves

Safety interlock devices

Test Procedures

Ensure a minimum of 5 meters of clear space around the installation area.

Connect the apparatus to 220V, 50Hz, 10A power supply.

Supply industrial propane and compressed air to the system.

Mount the test sample vertically on the water-cooled holder.

Adjust the radiation panel and calibrate heat flux sensors.

Ignite the sample using the small flame ignition system.

Monitor flame spread distance and propagation speed using the scale markings and digital sensors.

Record data for critical heat flux and flame spread classification.

After testing, shut off gas and air supply and allow the apparatus to cool before sample removal.

FAQ

1. What is this product?

The Surface Flame Spread Test Apparatus is a laboratory instrument used to evaluate the lateral flame propagation of materials for building and railway safety compliance.

2. What is it used for?

It measures flame spread distance, propagation speed, and critical heat flux to classify materials according to international fire safety standards.

3. How does it work?

The sample is exposed to a small flame and controlled radiant heat. Heat flux sensors and a scale-marked holder monitor flame extension to determine the material’s flame spread rating.

4. Why is it important?

Understanding surface flame propagation is critical for preventing fire hazards in buildings, railway vehicles, and interior materials, ensuring safety and compliance with international standards.

5. Which industries is it suitable for?

This apparatus is ideal for the building materials, railway, automotive interior, and laboratory research sectors.

Leave Message Get Price