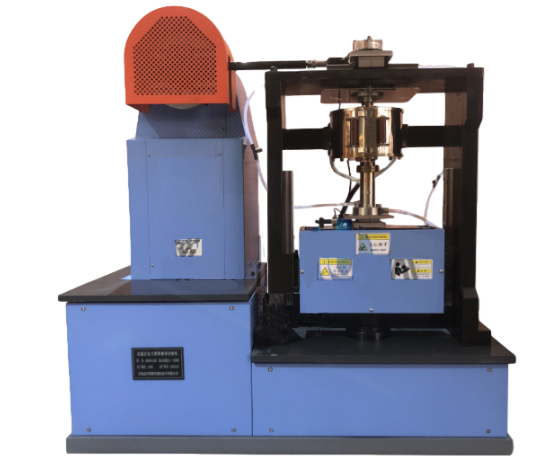

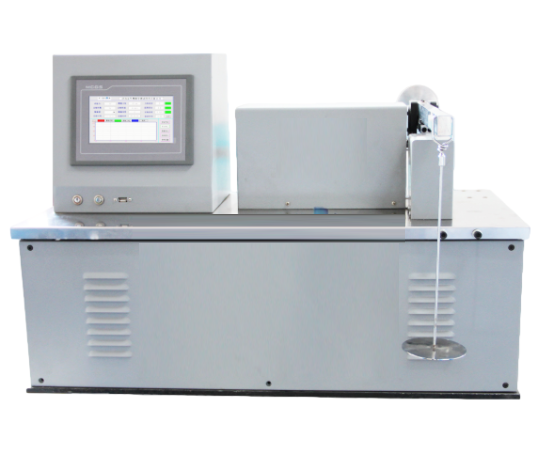

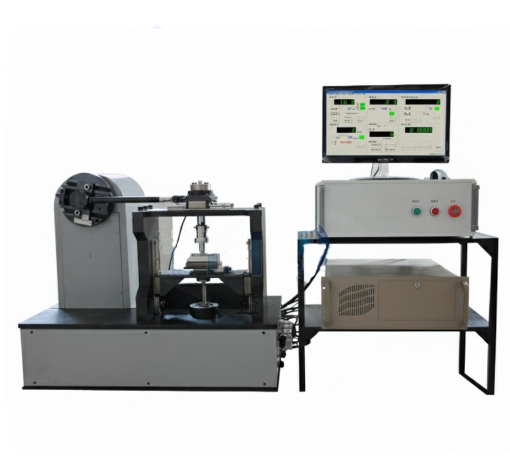

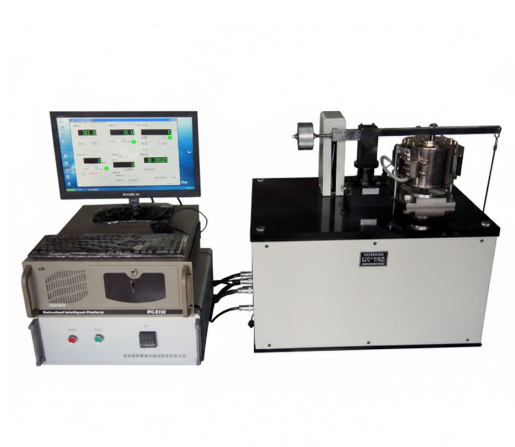

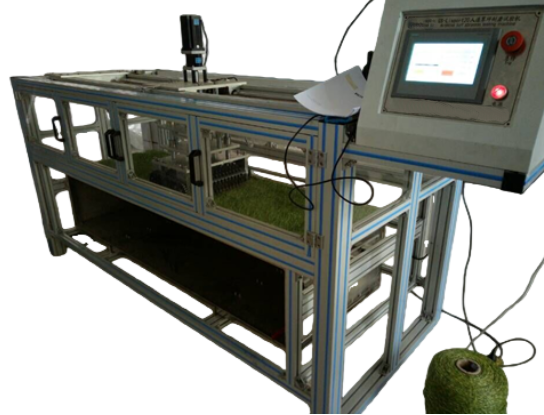

OSU Rate of Heat Release Apparatus

The OSU Rate of Heat Release Apparatus is a precision instrument designed to measure the heat release rate (HRR) of materials, primarily for aerospace applications. Originally developed by Smith at Ohio State University in 1972. this apparatus has become an FAA-approved testing instrument for evaluating the combustion behavior of aircraft materials. You can use it to accurately determine heat release rates, flame spread, and smoke generation in compliance with international aviation safety standards, including FAR Part 25 Appendix F Part IV, Airbus AITM 2.0006. and Boeing BSS 7322. Its stainless-steel combustion chamber, PID-controlled heating system, and advanced data acquisition software enable reliable, reproducible results in a controlled laboratory environment.

Application

The OSU Rate of Heat Release Apparatus is widely used in the following areas:

Aerospace Material Testing: Assess heat release, flame spread, and smoke generation of aircraft cabin materials according to FAA, Airbus, and Boeing standards.

Aircraft Interior Compliance: Evaluate materials for FAR Part 25 Appendix F Part IV, ensuring cabin safety during fire scenarios.

Material Research & Development: Determine thermal degradation and combustion characteristics of plastics, composites, and coatings for aerospace applications.

Fire Safety Laboratory Testing: Integrate HRR data with flame spread and smoke density evaluations to support fire safety certification.

Typical test materials include aircraft cabin panels, interior plastics, textiles, laminates, and composite materials.

Standards

The apparatus supports compliance with the following standards:

BSS 7322 – Aerospace materials flame spread, smoke density, and toxicity evaluation.

AITM 2.0006 – Aerospace materials flame spread and smoke generation measurement.

FAR Part 25 Appendix F Part IV – Aircraft cabin material flame spread and smoke toxicity requirements.

GB/T 27904‑2011 – Flame spread performance of interior decoration materials (can be combined with HRR testing).

GB 8624‑2012 – Classification of combustion performance of building materials and products (can be combined with HRR results).

Parameters

| Parameter Category | Details |

|---|---|

| Dimensions | 760 mm (W) × 1850 mm (H) × 850 mm (D) |

| Weight | 218 kg |

| Combustion Chamber | Stainless steel with high-temperature glass viewing window |

| Heat Radiation Source | 4 Glowbar heating rods, up to 35 kW/m² flux |

| Temperature Control | 2 independent PID controllers |

| Power Supply | 220 V, 35 A |

| Operating Temperature | 10°C – 35°C |

| Combustion Gas | Methane |

| Auxiliary Gas | Constant temperature and flow air supply |

Features

Stainless-steel combustion chamber with high-temperature observation window.

Four Glowbar heating rods providing up to 35 kW/m² radiant heat flux.

Dual PID temperature controllers for precise heat regulation.

Fully automatic pneumatic sample feeding and shielded door system.

Upper stationary burner and movable lower burner for flexible testing.

Rotor flow meters for controlling upper and lower burner gas flow.

Movable T-shaped calibration burner and flow controller for system calibration.

Mass flow controllers automatically applied to thermopile calibration.

Water-cooled heat flux sensors for accurate measurement of irradiated heat.

Airflow temperature control system for constant temperature and flow within the test chamber.

Orifice flow meters to monitor flow rate and pressure entering the test chamber.

Integrated data acquisition system and standard HRR testing software.

Accessories

Water-cooled heat flux sensors

Pneumatic sample feeder and shielded door

Upper and lower burners with flow control

T-shaped calibration burner

Rotor and mass flow controllers

PID temperature controllers

Data acquisition hardware and HRR software

Test Procedures

Ensure installation space allows safe operation and access.

Connect the apparatus to a 220 V, 35 A power supply.

Provide constant-temperature, constant-flow auxiliary gas.

Connect methane as the combustion gas supply.

Mount the test sample in the combustion chamber.

Adjust Glowbar heating rods and set PID controllers to desired heat flux.

Activate the automatic sample feeder and shielded door system.

Ignite the sample and upper/lower burners.

Monitor heat release rate, temperature, and gas flow using the software interface.

Record data for HRR, flame spread, and smoke generation.

After testing, shut off gas supply and allow the chamber to cool before sample removal.

FAQ

1. What is this product?

The OSU Rate of Heat Release Apparatus is a laboratory instrument designed to measure heat release rates, flame spread, and smoke generation of materials, primarily for aerospace applications.

2. What is it used for?

It evaluates the combustion performance of aircraft materials, ensuring compliance with FAA, Airbus, and Boeing fire safety standards.

3. How does it work?

The instrument exposes the material to controlled radiant heat using Glowbar heating rods. Heat flux sensors, temperature controllers, and burners measure the heat release rate and flame spread under precise airflow and temperature conditions.

4. Why is it important?

Accurate HRR measurements are critical for aircraft cabin fire safety, helping to prevent catastrophic incidents and ensuring compliance with international aviation standards.

5. Which industries is it suitable for?

It is suitable for aerospace, aircraft interior material manufacturing, fire safety laboratories, and R&D centers evaluating thermal and combustion properties of materials.

Leave Message Get Price