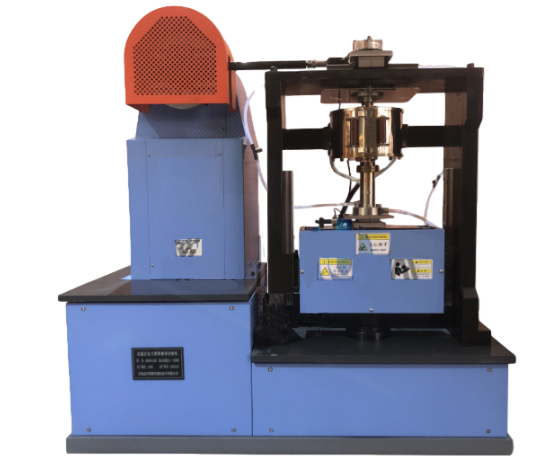

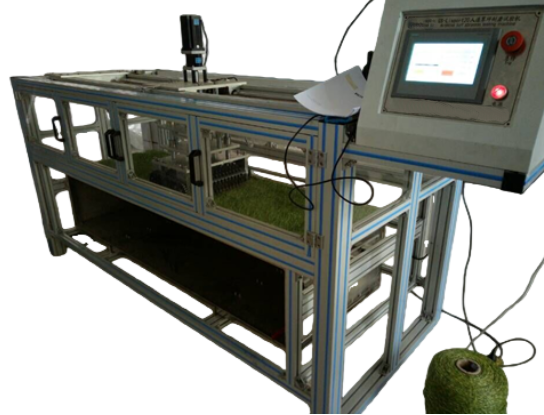

IEC 60112 Electronic Tracking Index Tester

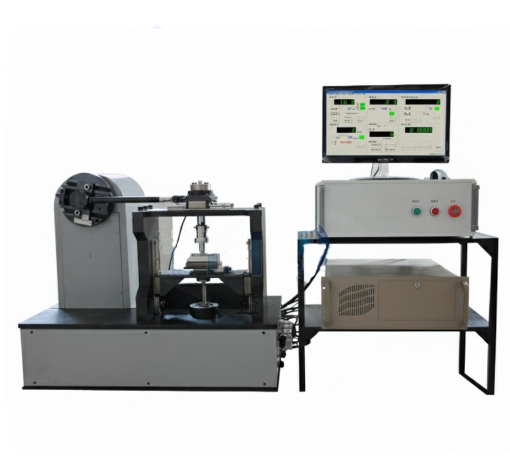

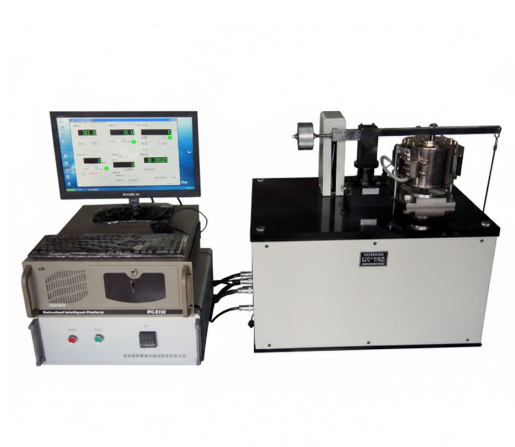

The Electronic Tracking Index Tester is designed for evaluating the electrical tracking resistance of solid insulating materials. It measures the Comparative Tracking Index (CTI) and Proof Tracking Index (PTI) in accordance with DIN EN 60112 and DIN EN 60695-2 standards. The instrument delivers accurate, repeatable, and safe testing of insulation surfaces under controlled electrolyte droplet conditions.

Application Scenarios

(1) Electrical insulation materials testing: evaluating PTI and CTI of plastics, ceramics, and composite insulating materials

(2) Electronic component manufacturing: assessing insulation resistance and surface tracking of switchgear, connectors, and PCB substrates

(3) Cable and wire industry: testing solid insulation on wires, cables, and coated conductors

(4) Transformer and motor components: evaluating insulating parts for tracking resistance under high voltage stress

(5) Research and development laboratories: developing new polymer composites, epoxy resins, and insulating materials

(6) Educational institutions: teaching high-voltage testing methods, insulation safety, and CTI/PTI measurement principles

(7) QC and inspection laboratories: routine verification of insulation performance for compliance with international standards

Compliance Standards

(1) DIN EN 60112 — Method for determining the Comparative Tracking Index (CTI) of solid insulating materials

(2) DIN EN 60695-2 — Fire hazard testing — Part 2: Test methods for tracking and surface resistance

(3) IEC 60112 — Electrical insulating materials — Determination of tracking resistance

(4) Relevant ISO and national standards for electrical insulation safety testing

Key Features

(1) Measures Comparative Tracking Index (CTI) and Proof Tracking Index (PTI)

(2) Adjustable test voltage, current, extinguishing time, droplet size, and droplet count

(3) R.M.S display of current and voltage for precise monitoring

(4) Automatic droplet interval: 30 seconds per droplet

(5) Safe testing environment with controlled electrolyte application between platinum electrodes

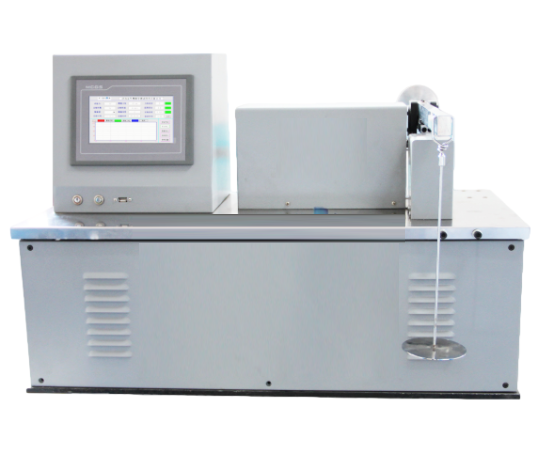

(6) Compact control and test units for laboratory placement

(7) Includes essential accessories: platinum electrodes, droppers, and glass test plate

Technical Parameters

| Parameter | Specification |

|---|---|

| Test Target | CTI / PTI |

| Test Voltage | 0–600 V (adjustable) |

| Test Current | Adjustable |

| Droplet Interval | 30 seconds |

| Droplet Size | Adjustable |

| Droplet Count | Adjustable (typically 50 droplets per sample) |

| Units Dimensions (W×H×L) | Control Unit: 610 × 305 × 600 mm; Test Unit: 610 × 550 × 450 mm |

| Weight | Approx. 27 kg |

| Power Supply | 230 V |

| Accessories | Platinum electrodes, droppers, glass test plate |

Product Advantages

Accurate measurement of CTI and PTI for solid insulating materials

Adjustable testing parameters allow simulation of real-world insulation stress conditions

R.M.S monitoring ensures precise voltage and current tracking

Safe and reliable droplet-based testing method

Compact design suitable for laboratory or production QC environments

Essential for insulation development, quality control, and standard compliance

FAQ

(1) What is the Electronic Tracking Index Tester?

It is a precision instrument for determining the Comparative Tracking Index (CTI) and Proof Tracking Index (PTI) of solid insulating materials.

(2) What is this equipment used for?

It is used to evaluate electrical insulation resistance and surface tracking characteristics of plastics, ceramics, wires, cables, and polymer composites.

(3) What types are available?

Standard laboratory units with adjustable voltage and droplet control; optional configurations for higher voltage or multiple sample testing available.

(4) What industry problems can it solve?

Ensures insulation materials meet safety standards, prevents electrical failures due to tracking, and verifies material suitability for high-voltage applications.

(5) How is it operated?

Place the sample on the glass test plate, adjust test voltage and droplet parameters, start automatic droplet application, and record the highest voltage at which no tracking failure occurs (CTI/PTI).

Leave Message Get Price