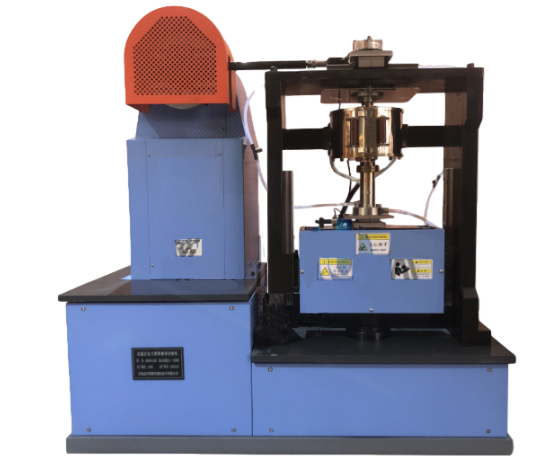

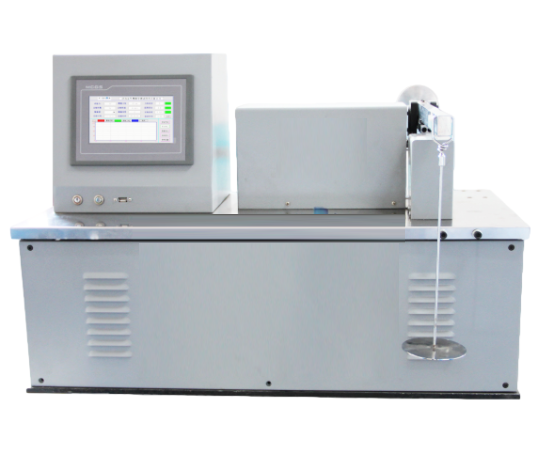

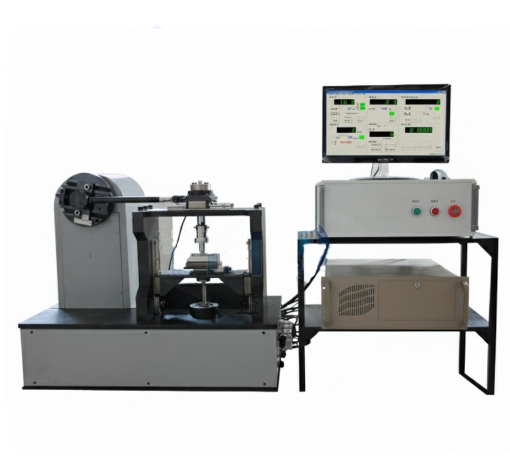

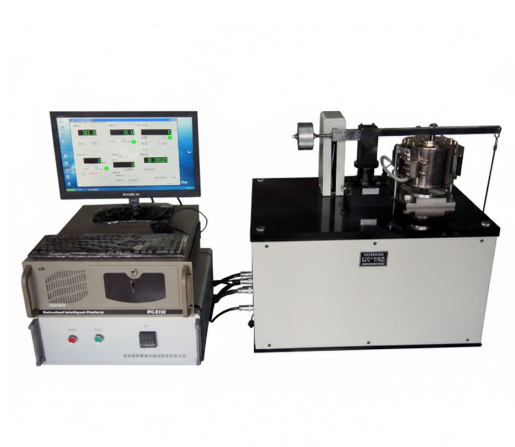

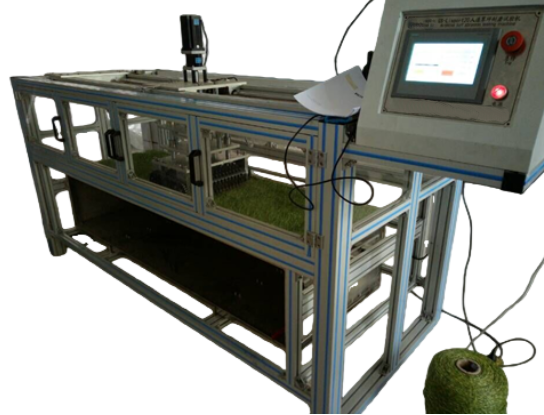

Fiber Oil Extractor

The Fiber Oil Extractor, also known as the Rapid Grease Extraction Apparatus, is designed for rapid and accurate determination of grease or finish content in wool, synthetic fibers, yarns, or fabrics. Using solvent percolation and evaporation, the apparatus delivers fast results suitable for quality control, processing, and research purposes in textile production. Multiple extraction units can operate simultaneously for higher throughput.

Application Scenarios

(1) Wool processing plants: determining grease content in wool tops, combed slivers, and raw wool batches

(2) Synthetic fiber production lines: monitoring finishing oil content in polyester, nylon, acrylic, and blended fibers

(3) Yarn production: quality control for finished yarns and spun fibers

(4) Textile laboratories: research and development of fiber treatments, lubricants, and finishing processes

(5) Fabric testing: analyzing fabrics after disintegration into yarn for grease or finish content

(6) Educational institutions: practical training in fiber analysis and quality control procedures

(7) Comparative evaluation: assessing different fiber batches, supplier lots, or treated fibers for consistent oil content

Compliance Standards

(1) Edana Method ERT 155 — Determination of grease or finish content in wool and synthetic fibers

(2) ISO 139 — Wool: Determination of grease content

(3) ASTM D6140 — Standard Test Method for Grease and Oil Content in Wool

(4) Relevant textile QC practices for synthetic and blended fibers

Key Features

(1) Multi-unit design allows 1, 2, or 3 extraction units for simultaneous testing

(2) Simple percolation principle ensures rapid and reliable oil extraction

(3) Temperature-controlled hot-plate provides consistent solvent evaporation

(4) Adjustable plunger and weight system ensures uniform packing and pressure in the extraction tube

(5) Suitable for wool, synthetic fibers, yarns, and fabrics (after disintegration into yarn)

(6) Durable and easy-to-operate pedestal, extraction tube, plunger, cotton plug, tray, and hot-plate

Technical Parameters

| Parameter | Specification |

|---|---|

| Temperature Range | Ambient – 250 °C |

| Temperature Accuracy | ±1 °C |

| Timing Range | 1–9999 min |

| Number of Specimens | 3 simultaneous |

| Solvent Types | Petroleum ether, ether, dichloromethane |

| Loading Mode | Weighted plunger system |

| Extraction Tube Size | Standard tube for fiber, yarn, or sliver |

| Outer Dimensions (L×W×H) | 170 × 170 × 380 mm |

| Weight | 4.4 kg |

| Power Supply | AC 220V, 720 W |

| Power Dissipation | ≥175 W |

Product Advantages

Rapid and accurate determination of grease or finish content in fibers and yarns

Multi-unit design improves laboratory throughput and efficiency

Temperature-controlled hot-plate ensures consistent extraction conditions

Adjustable plunger system guarantees uniform packing and pressure

Versatile for wool, synthetic fibers, yarns, and disintegrated fabrics

Simple operation and durable construction suitable for labs and educational institutions

FAQ

(1) What is the Fiber Oil Extractor?

It is a laboratory instrument used to determine the grease or finish content in wool, synthetic fibers, yarns, and fabrics.

(2) What is this equipment used for?

It is used for fiber quality control, monitoring finishing oil content, and evaluating fiber treatment processes in production and research labs.

(3) What types are available?

Single, double, or triple extraction unit configurations for different throughput requirements.

(4) What industry problems can it solve?

Ensures accurate measurement of grease or finish content, supports QC in wool and synthetic fiber production, and assists in R&D of fiber finishing processes.

(5) How is it operated?

Load fiber or yarn into the extraction tube, apply weighted plunger, run solvent percolation on the temperature-controlled hot-plate, then evaporate solvent and read grease content.

Leave Message Get Price