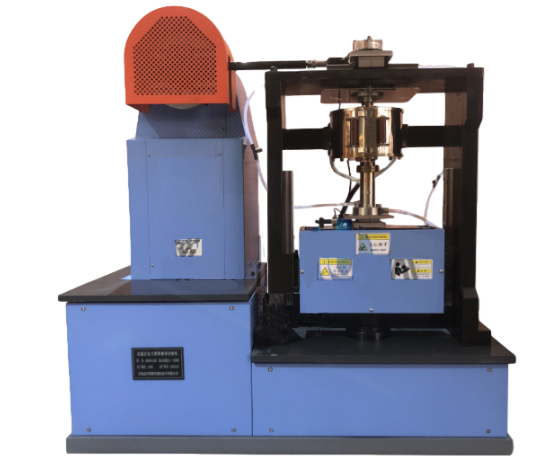

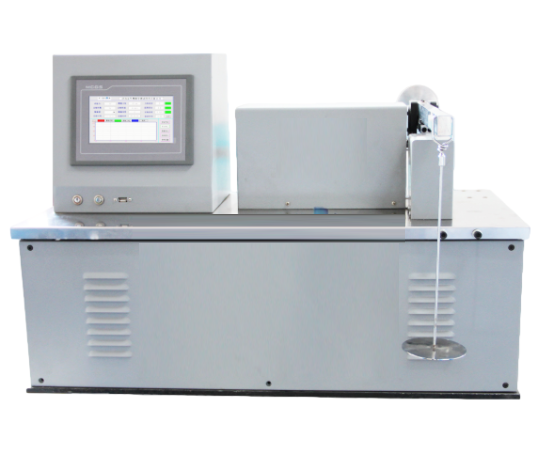

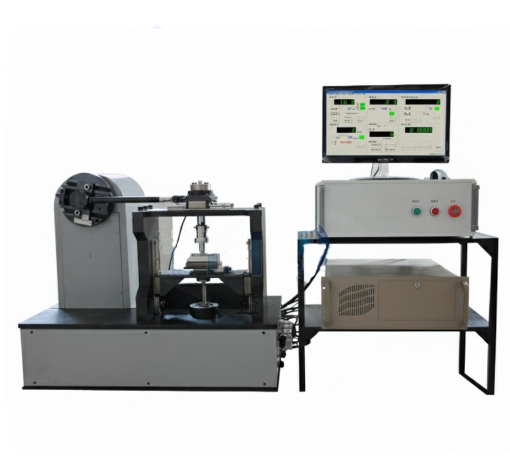

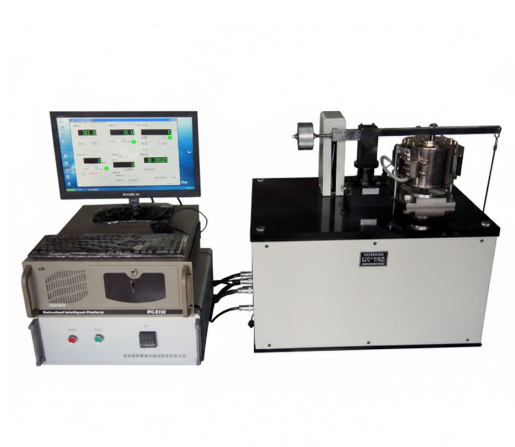

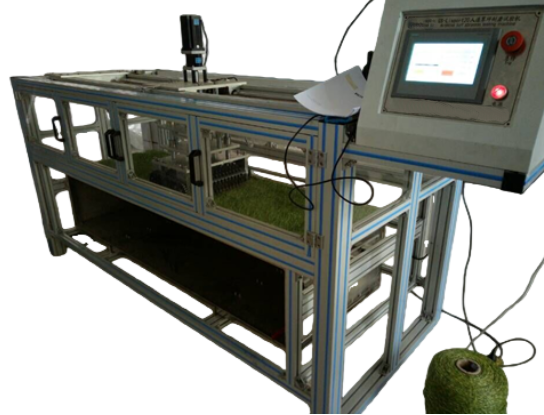

Flatbed Ironing Tester

The Flatbed Ironing Tester is a laboratory-grade instrument designed to simulate real-world ironing conditions for evaluating fabric thermal performance. It assesses crease recovery, heat resistance, dimensional stability, shrinkage behavior, and surface appearance changes. Ideal for quality control, production inspection, and textile R&D, it delivers consistent, repeatable, and standard-compliant test results.

Application

(1) Apparel fabrics: cotton, polyester, wool, nylon, spandex, and blends for wrinkle recovery, shrinkage, and heat resistance

(2) Home textiles: bedding, upholstery, curtains, and table linens for heat-setting and surface quality evaluation

(3) Industrial fabrics: automotive interiors, filtration materials, and protective garments

(4) Functional textiles: flame-retardant fabrics, coated fabrics, waterproof/breathable laminates

(5) Laminated materials: PU/PVC synthetic leather, soft-touch coatings, printed laminates

(6) Finished fabrics requiring wrinkle-resistant, shrink-resistant, or heat-set performance

(7) Smart and sensitive textiles: wearable electronics or temperature-adaptive fabrics requiring controlled thermal tests

(8) QC laboratories, inspection institutes, textile mills, and educational institutions for process control

(9) Forensic analysis of heat-damaged textiles and garment care research

Compliance Standards

(1) ISO 3795 — Textiles — Determination of the burning behavior of materials used in apparel and furnishings (for functional and flame-retardant fabrics)

(2) ISO 5077 — Textiles — Determination of dimensional change in washing and drying (for shrinkage assessment)

(3) AATCC TM66 — Wrinkle Recovery of Fabrics: Appearance Method

(4) GB/T 3810-2006 — Flat ironing test for textiles

(5) EN 13591 — Textiles — Determination of crease recovery and heat resistance of apparel and household fabrics

Key Features

(1) Realistic ironing simulation: Accurately reproduces domestic and industrial ironing conditions

(2) Multi-function testing: Supports crease recovery, shrinkage, and heat-setting evaluations

(3) Touchscreen control: 7-inch display with programmable test sequences

(4) Stable & repeatable performance: Uniform heating and reliable pressure control

(5) Built-in data logging: Test parameters can be exported for documentation

(6) Enhanced safety system: Overheat protection and interlock safety switch

(7) Low-maintenance design: Easy-clean platform and durable heating system

Technical Parameters

| Parameter | Specification |

|---|---|

| Temperature Range | Ambient +20 °C to 300 °C |

| Heating Rate | 10 °C/min (programmable) |

| Temperature Uniformity | ±2 °C across test area |

| Pressure Control | 0.5–5 kPa adjustable |

| Test Area | 300 × 300 mm heated flatbed |

| Cooling System | Forced-air cooling (30 °C recovery in 5 min) |

| Power Supply | 220 V / 50 Hz, 1.5 kW |

| Dimensions | 600 × 500 × 1200 mm (W×D×H) |

| Weight | 45 kg |

| Control System | 7-inch touchscreen with programmable sequences |

Product Advantages

Accurately simulates real-world ironing conditions for fabrics and laminated materials

Multi-functional testing for wrinkle recovery, shrinkage, heat-setting, and surface evaluation

Programmable sequences and touchscreen interface for easy operation

Uniform heating and reliable pressure control for repeatable results

Built-in data logging for quality control and documentation

Enhanced safety features including overheat protection and interlock system

Low-maintenance design suitable for textile mills, QC labs, and research institutions

FAQ

(1) What is the Flatbed Ironing Tester?

It is a laboratory instrument that simulates ironing to evaluate thermal performance, crease recovery, shrinkage, and surface changes of textiles.

(2) What is this equipment used for?

It is used for assessing wrinkle recovery, heat resistance, dimensional stability, shrinkage behavior, and surface appearance of fabrics, home textiles, industrial textiles, and laminated materials.

(3) What types are available?

Standard flatbed ironing tester with programmable 7-inch touchscreen; optional customized bed size or multi-sample testing available.

(4) What industry problems can it solve?

It helps ensure consistent thermal performance, verify shrinkage and wrinkle resistance, support QC in textile production, and evaluate functional and laminated fabrics.

(5) How is it operated?

Load the sample, set temperature, pressure, and test sequence on the touchscreen, start the test; the system maintains uniform heating, pressure, and records test data automatically.

Leave Message Get Price