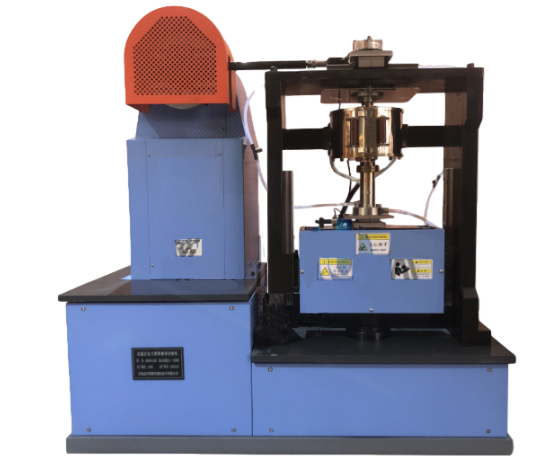

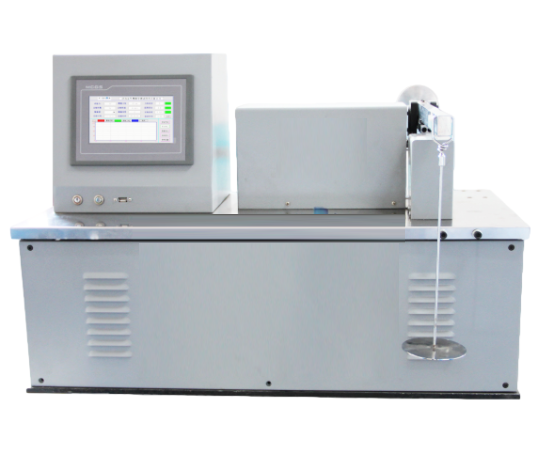

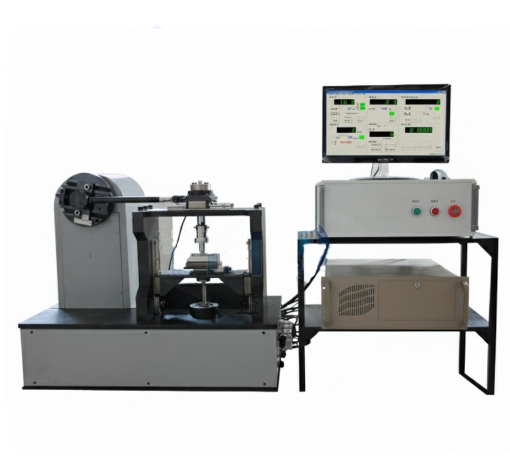

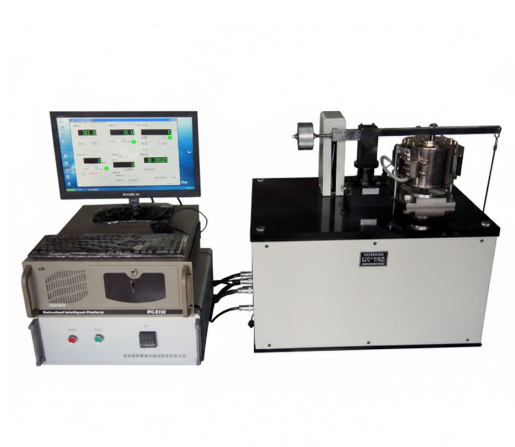

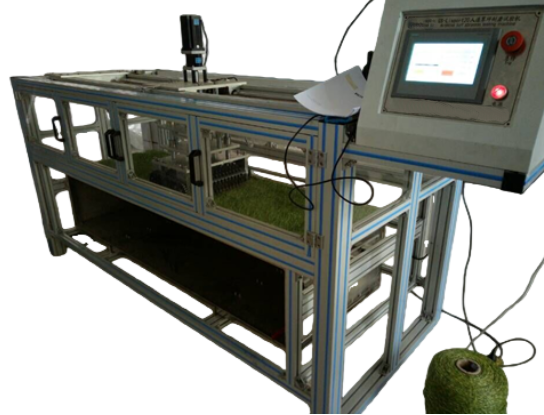

Textile moisture absorption and heat generation performance tester

The Textile Moisture Absorption and Heat Generation Performance Tester is a laboratory instrument designed to evaluate the thermal response of textiles when absorbing moisture. By simulating real-use humidity and airflow conditions, it measures temperature rise, heat-release characteristics, and thermal comfort performance of fabrics, fibers, yarns, and finished garments. It is widely used in the development and quality control of moisture-absorbing and heat-generating functional textiles, including thermal underwear, sportswear, outdoor apparel, bedding materials, and smart temperature-regulating fabrics.

Application Scenarios

(1) Functional thermal underwear: evaluating moisture-induced heat generation and thermal comfort

(2) Sportswear and outdoor performance fabrics: testing fibers, yarns, and finished garments for thermal response under sweat or humidity

(3) Fiber and yarn development: assessing hygroscopic-exothermic treatments on raw fibers and spun yarns

(4) Fabrics with moisture-activated heat generation: testing treated fabrics for winter clothing, jackets, and thermal layers

(5) Winter apparel and insulation materials: measuring thermal comfort of coats, down jackets, quilted garments, and ski wear

(6) Bedding and home textiles: evaluating quilts, blankets, mattress toppers, pillow fillings, and mattress fabrics

(7) Medical textiles: testing hospital gowns, patient bedding, and temperature-regulating medical fabrics

(8) Smart textiles and temperature-adaptive fabrics: assessing heat generation for wearable electronics, adaptive sportswear, and intelligent fabrics

(9) Research and teaching: providing reliable data for textile engineering labs, R&D of functional fabrics, and academic experiments

(10) Quality control: manufacturers and inspection institutes use it to ensure consistent thermal performance of moisture-absorbing and heat-generating textiles

Standards

(1) GB/T 29866-2013 — Test method for moisture absorption and heat generation performance of textiles

(2) FZ/T 73036-2010 — Moisture absorption and heat-generating thermal underwear standard

(3) ISO 18625 — Textiles — Determination of heat generated during wetting of fabrics

(4) ASTM F1868 — Standard Test Method for Thermal and Evaporative Resistance of Clothing Materials

(5) EN 31092 — Clothing — Physiological effects — Measurement of thermal resistance and water-vapour resistance under steady-state conditions

(6) ISO 11092 — Textiles — Physiological effects — Measurement of thermal and water-vapour resistance under steady-state conditions

(7) AATCC TM195 — Test Method for Evaluation of Thermal Absorption of Fabrics

Key Features

(1) High-precision thermal measurement: Fast-response sensors accurately capture temperature rise during moisture absorption

(2) Controlled environmental simulation: Stable control of humidity, airflow, and temperature ensures repeatable test conditions

(3) Multi-sample testing: Supports multi-channel testing (e.g., 4 channels) to improve laboratory efficiency

(4) Stable and uniform chamber design: Optimized airflow and thermal insulation maintain consistent environmental conditions

(5) User-friendly operation: Digital display, programmable test time, and intuitive interface ensure easy operation

Technical Parameters

| Parameter | Specification |

|---|---|

| Temperature Rise Range | 0–100 °C |

| Temperature Resolution | 0.01 °C |

| Temperature Fluctuation | ≤ ±0.5 °C |

| Relative Humidity Range | 30%–90% ± 3% |

| Air Velocity | 0.3–0.5 m/s (adjustable) |

| Test Time Range | 0 min 01 s – 99 min 59 s |

| Time Resolution | 1 second |

| Detection Channels | 4 channels |

| Chamber Size | 350 × 300 × 400 mm (W×D×H) |

| Chamber Material | Stainless steel with thermal insulation |

| Environmental Control System | Heating, humidification, refrigeration, air circulation |

| Power Supply | AC 220V / 50Hz |

Product Advantages

High-precision sensors ensure accurate measurement of temperature rise during moisture absorption

Stable environmental control for humidity, airflow, and temperature ensures repeatable testing

Multi-channel testing improves laboratory efficiency and throughput

Optimized chamber design ensures uniform thermal and humidity conditions

Intuitive digital interface simplifies operation and test programming

Provides essential data for product development, quality control, and R&D

FAQ

(1) What is this tester?

It is a laboratory instrument for measuring the thermal response of textiles during moisture absorption.

(2) What is this equipment used for?

It evaluates temperature rise, heat-release characteristics, and thermal comfort of fabrics, fibers, yarns, and finished garments.

(3) What types are available?

Standard 4-channel tester; custom configurations may be available depending on laboratory requirements.

(4) What industry problems can it solve?

It helps assess functional textile performance, optimize product design, verify quality of moisture-absorbing and heat-generating fabrics, and support research and development of thermal comfort textiles.

(5) How is it operated?

Load samples, set test time, airflow, temperature, and humidity parameters, and start the test; the system automatically controls the environment and records temperature changes.

Leave Message Get Price