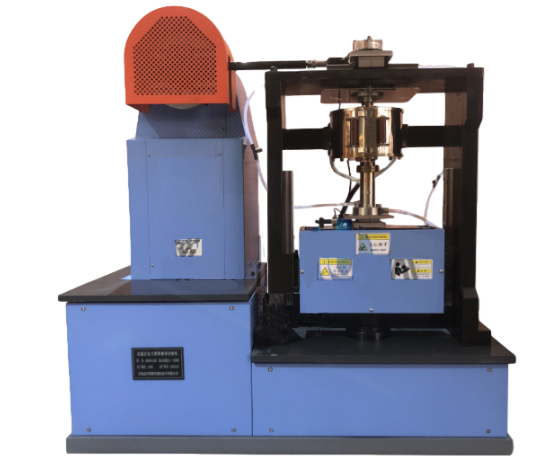

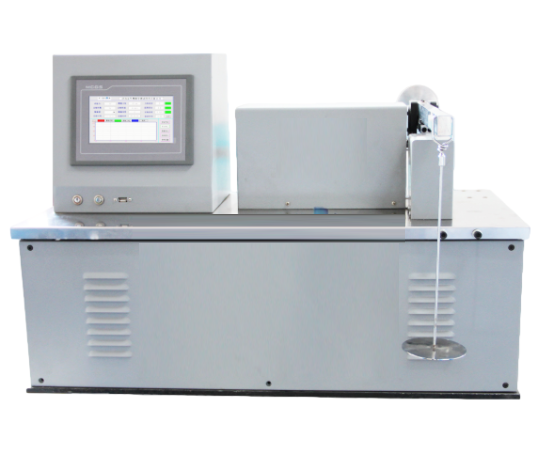

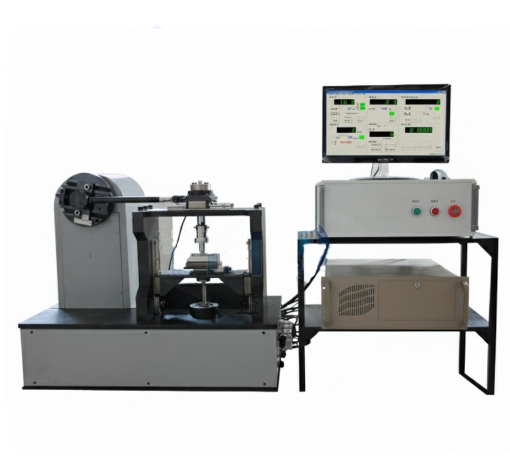

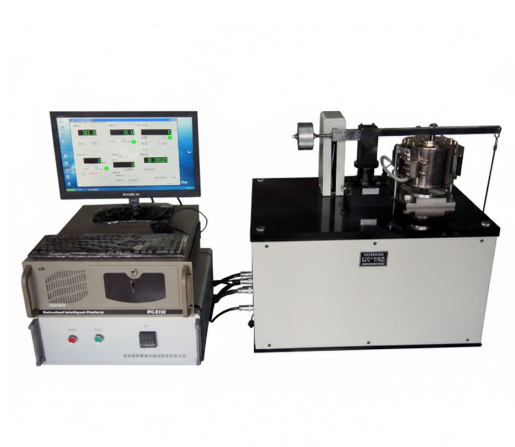

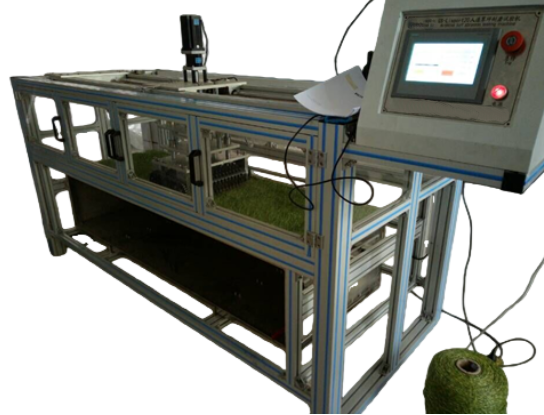

Cone Calorimeter Tester | ISO 5660, ASTM E1354

The Cone Calorimeter Tester is one of the most important bench-scale instruments in modern fire testing. Heat release rate is the core indicator for evaluating the fire behavior of materials and products. Conventional methods made this parameter difficult to measure; however, with the development of oxygen consumption calorimetry, it is now possible to accurately determine the heat released during combustion.

The Cone Calorimeter Tester provides a controlled environment for measuring heat release rate, mass loss, smoke production and other key combustion properties. The system supports all major international standards, and its modular structure allows laboratories to purchase required components first—such as heat release or smoke generation modules—and expand later into a fully configured system. This flexibility is one of the major advantages of the instrument.

Applications

The Cone Calorimeter Tester is widely used in laboratories, certification bodies and research institutes for evaluating the fire performance of a broad range of materials and end-use products. Typical application scenarios include:

(1) Building materials

Assessment of insulation boards, wall panels, flooring materials, façade cladding, fireproof coatings and structural components to determine heat release, mass loss and smoke generation.

(2) Transportation interiors

Testing of materials used in aircraft, trains, ships and automobiles, including seat cushions, cabin panels, composites and decorative laminates, to evaluate compliance with fire safety regulations.

(3) Polymeric materials and composites

Combustion analysis of plastics, rubber, carbon-fiber composites, epoxy laminates, foams, and fiber-reinforced materials, supporting material development and quality control.

(4) Textiles and flexible materials

Evaluation of upholstery fabrics, curtains, carpets, nonwovens and other textile products to determine ignition characteristics and smoke release behavior.

(5) Electrical and electronic products

Testing of housings, circuit board substrates, cable insulation and other components to understand their thermal decomposition and flammability risks.

(6) Research and product development

Used in universities and R&D centers for studying combustion mechanisms, optimizing material formulations, and improving fire safety performance.

Standards Compliance

The Cone Calorimeter Tester fully complies with the following national and international standards:

GB/T 16172-2007

Test Method for Heat Release Rate of Building Materials

ISO 5660

Reaction-to-fire tests — Heat release, smoke production and mass loss rate

ASTM E 1354

Standard Test Method for Heat and Visible Smoke Release Rates Using an Oxygen Consumption Calorimeter

ASTM E 1474

Standard Test Method for Determining the Heat Release Rate of Upholstered Furniture Components or Composites

ASTM E 1740

Standard Test Method for Determining the Heat Release Rate of Low Heat Release Rate Materials

ASTM F 1550

Standard Test Method for Determining the Combustion Dynamics of Materials

ASTM D 6113

Standard Test Method for Using a Cone Calorimeter to Determine Fire-Test-Response Characteristics of Materials

NFPA 264

Standard Method for Heat and Visible Smoke Release Rates for Materials and Products

CAN/ULC-S135

Standard Method of Fire Test of Heat Release Rate of Building Materials

BS 476 Part 15

Fire Tests on Building Materials and Structures — Method for Measuring the Rate of Heat Release

System Configuration (Complete Setup)

Cone Heater

230 V, 5000 W heater mounted inside a truncated cone, providing up to 100 kW/m² radiant heat.

Horizontal/Vertical Sample Holder

Holds 100 mm × 100 mm specimens up to 50 mm thick.

Temperature Control

Three Type-K thermocouples with PID controllers for precise regulation.

Shutter Mechanism

Protects the specimen before testing, ensuring stable initial mass and preventing premature ignition.

Load Cell

High-precision mass measurement with 0.01 g resolution and mechanical overload protection.

Spark Igniter

10 kV ignition system with automatic positioning and safety interlock.

Exhaust System

Stainless steel hood, sampling probe, adjustable exhaust fan (0–50 g/s), and orifice flow meter.

Gas Sampling Train

Includes particulate filter, cold trap, pump, drying column and flow controller.

Oxygen Analyzer

Paramagnetic O₂ analyzer with 0–25% measurement range.

Smoke Density Measurement

Helium-neon laser system with primary and secondary photodetectors, including ND filters.

Heat Flux Meter

Used for calibrating irradiance to the specimen surface.

Burner Calibration System

Uses 99.5% methane for heat release calibration.

Data Acquisition System

High-speed DAQ with 22-bit resolution, 250 channels/s scanning, and 50,000-point memory.

Control & Analysis Software

Windows-based interface supporting:

Instrument control

Calibration management

Real-time monitoring

Standard-compliant data reporting

Multi-test averaging

FDMS data format

CSV exporting

Optional Configurations

CO and CO₂ measurement (NDIR analyzers)

HCl gas analysis with heated sampling lines

Controlled-atmosphere testing for low-oxygen environments

Mass loss calorimeter

FTIR toxicity analysis system

Operator protection door

FAQ

(1) What is the main purpose of the Cone Calorimeter Tester?

It measures heat release rate, mass loss, smoke production and combustion characteristics, which are essential parameters for evaluating fire safety.

(2) Why is heat release rate important?

Heat release rate directly determines how fast a fire grows. It is one of the most reliable indicators of material fire hazard.

(3) What types of materials can be tested?

Building products, plastics, foams, composites, textiles, wood products, cables and many other combustible materials.

(4) What specimen size is required?

Standard samples are 100 mm × 100 mm, with thickness up to 50 mm.

(5) Can the system be upgraded later?

Yes. Laboratories often start with heat release modules and later add smoke measurement, toxicity, or gas analysis components.

(6) Does it support both horizontal and vertical testing?

The system supports both orientations to match different standards and material types.

(7) How is the exhaust calibrated?

Using a methane burner and an orifice flow meter to establish accurate heat release measurement.

Leave Message Get Price