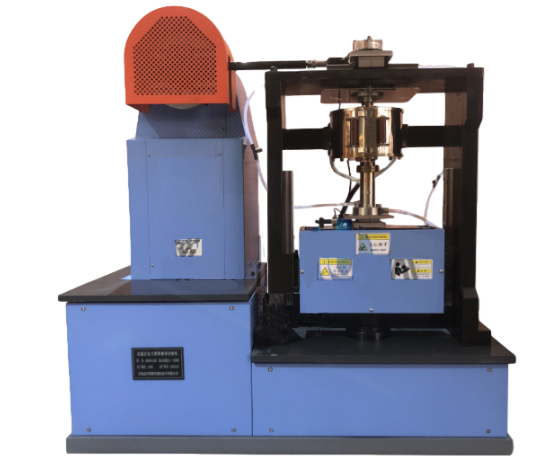

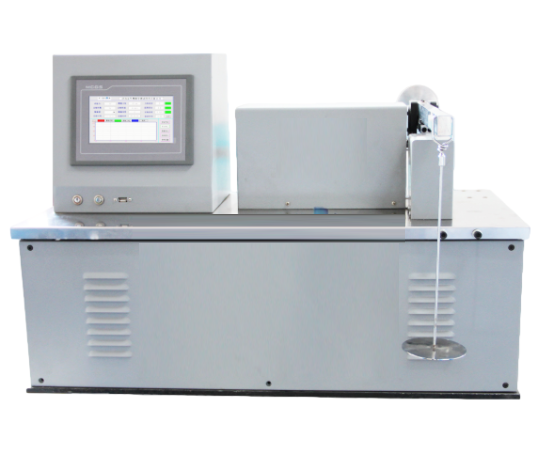

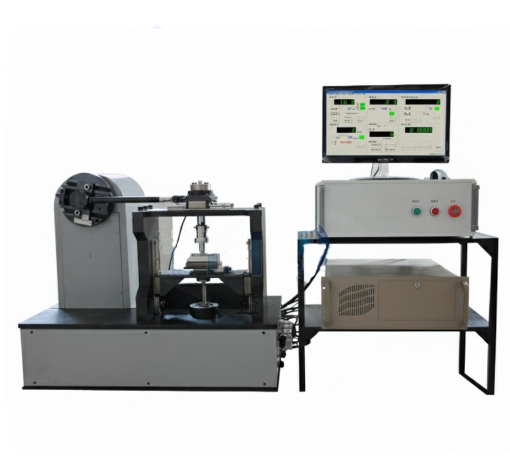

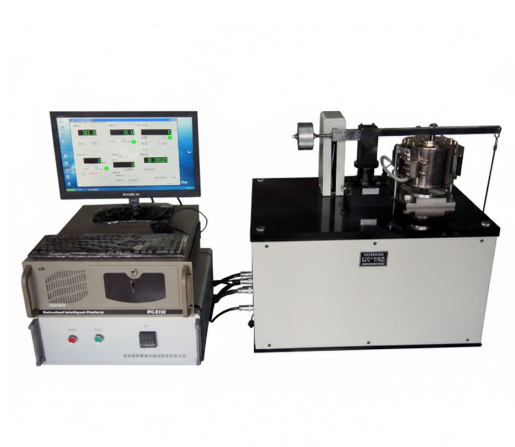

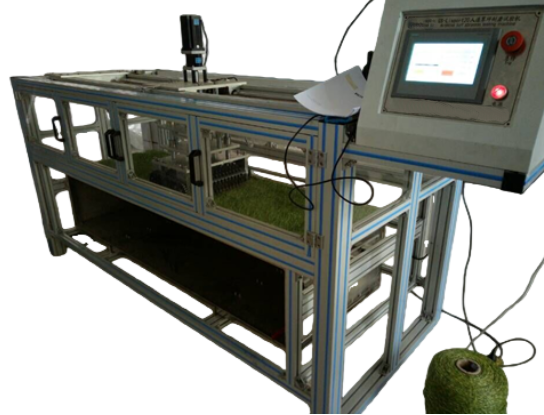

Double-Plate Thermal Conductivity Tester

The Double-Plate Thermal Conductivity Tester is a fully automated, computer-controlled instrument designed for steady-state thermal conductivity measurement. Integrated with a constant-temperature water bath and precision control system, it provides highly stable testing for a wide variety of homogeneous and non-homogeneous materials.

It is used for determining the thermal conductivity of plastics, rubber, glass, fiberboard, EPS/XPS insulation boards, foamed concrete, hollow glass units, wood panels, and other low-thermal-conductivity materials. With optional fixtures, the tester can also measure granular, powdered, loose-fill, and soft materials.

The tester is ideal for insulation-material manufacturers, quality inspection institutions, universities, and research laboratories engaged in heat-transfer research and product development.

Application

(1) Measurement of thermal conductivity in building insulation materials such as XPS, EPS, PU foam boards, phenolic foam, mineral wool, glass wool, rock wool, VIP panels, and other energy-efficient materials.

(2) Evaluation of plastics and elastomers including PP, PE, PVC, ABS, nylon, rubber sheets, and polymer composites.

(3) Testing of wood-based panels such as plywood, MDF, particleboard, fiberboard, bamboo panels, and WPC materials.

(4) Measurement of thermal resistance in architectural glass products including laminated glass, insulated glass units, and energy-saving glazing structures.

(5) Testing of lightweight foamed materials such as foamed concrete, foamed gypsum, foamed glass, and wall-panel core insulation.

(6) Evaluation of composite materials such as aluminum-plastic composites, glass-fiber boards, PU sandwich panels, honeycomb panels, and SIP insulation panels.

(7) Measurement of granular and loose-fill insulation such as perlite, vermiculite, fiber fill, and other backfill insulation materials using dedicated fixtures.

(8) Testing of textile and flexible thermal-insulation materials including insulation felts, padding materials, multilayer protective textiles, and flame-retardant fabrics.

(9) Testing of automotive thermal-management materials such as headliner insulation, engine heat shields, door-panel insulation, and interior sound-thermal composites.

(10) Evaluation of insulation components in household appliances including refrigerators, freezers, ovens, water heaters, and air-conditioning systems.

(11) Testing of packaging insulation such as cold-chain containers, foam insulation boxes, and temperature-controlled delivery packaging.

(12) Evaluation of thermal-management materials in energy storage systems such as battery insulation pads, thermal barriers, and phase-change composite materials.

(13) Research applications for advanced low-thermal-conductivity materials including aerogels, nano-insulation products, and high-performance foams.

(14) Testing of aerospace and transportation materials such as composite sandwich panels, lightweight insulation cores, and cabin thermal-insulation structures.

(15) Measurement of thermal performance in industrial insulation products such as pipeline insulation, furnace insulation boards, refractory panels, and lightweight refractory bricks.

Compliance Standards

Chinese Standards

GB/T 10294-2008 Steady-State Thermal Resistance and Related Properties

GB/T 3399-1982 Plastics — Thermal Conductivity Test — Guarded Hot Plate Method

GB/T 10801.1-2002 EPS Thermal Insulation Products

GB/T 10801.2-2002 XPS Thermal Insulation Products

GB/T 3139-2005 Thermal Conductivity of Fiber-Reinforced Plastics

GB/T 17794-2008 Flexible Elastomeric Insulation Products

International Standards

ISO 8302 Thermal Insulation — Determination of Steady-State Thermal Resistance

ISO 2582 Thermal Insulation — Measurement of Thermal Conductivity

ASTM C177 Standard Test Method for Steady-State Heat Flux Measurements

ASTM C518 Standard Test Method Using Heat Flow Meter Apparatus

ASTM C1113 Hot-Surface Thermal Conductivity of Refractories

EN 12667 Thermal Performance of Building Materials — Guarded Hot Plate Method

EN 12939 Thermal Conductivity of Thick Thermal Insulation Products

Technical Parameters

| Parameter | Specification |

|---|---|

| Operation Mode | Fully automatic |

| Specimen Size | 300 mm × 300 mm × (5–40) mm |

| Surface Flatness Requirement | 0.1 mm |

| Thermal Conductivity Range | 0.001–2.000 W/(m·K) |

| Accuracy | ±3% |

| Repeatability | ±1% |

| Temperature Resolution | 0.01°C |

| Temperature Control Accuracy | 0.05°C |

| Standard Specimen Thickness | 25 mm |

| Applicable Specimen Thickness | 5–40 mm |

| Thermal Resistance Requirement | ≥0.1 (m²·K)/W |

| Clamping Force | ≤2.5 kPa |

| Power Supply | 220V ±10%, 50Hz, 2.5 kW |

| Weight | 260 kg |

| Dimensions | 1100 mm × 1500 mm × 1500 mm |

FAQ

(1) What types of samples can this tester measure?

It supports solid boards, composites, glass, wood, polymers, foams, textiles, and granular or loose materials with optional fixtures.

(2) What is the recommended specimen thickness?

The standard thickness is 25 mm, and the tester supports specimens from 5 mm to 40 mm.

(3) Can the tester measure ultra-low thermal-conductivity materials?

Yes. With a lower limit of 0.001 W/(m·K), it accurately measures aerogels, nano-insulation materials, and advanced foams.

(4) Is the temperature system fully automated?

The tester integrates a computer-controlled water-bath system with high-precision PID control for stable, long-term operation.

(5) Which industries commonly use this tester?

Insulation-material production, construction materials, automotive, aerospace, household appliances, laboratories, universities, and quality-inspection agencies.

Leave Message Get Price