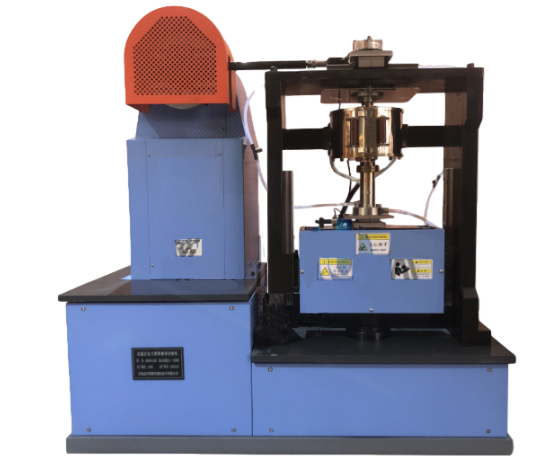

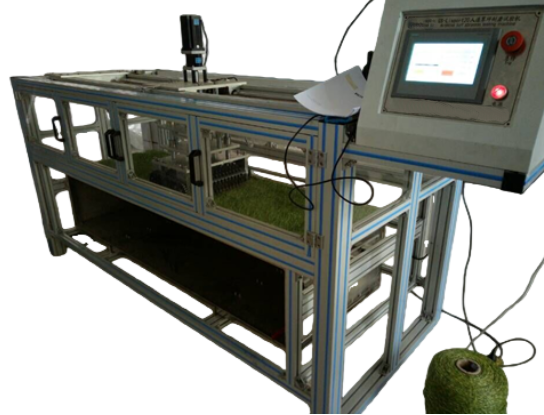

Steel Structure Fireproof Coating Testing Furnace

The Fire Resistance and Thermal Insulation Efficiency Test Furnace is a specialized testing instrument designed to evaluate the thermal insulation efficiency and fire resistance rating of steel structure fireproof coatings. The device is developed in accordance with GB14907-2018 Fireproof Coatings for Steel Structures and GB/T 9978-2008 requirements. It provides accurate, repeatable measurements for both indoor and outdoor fireproof coatings.

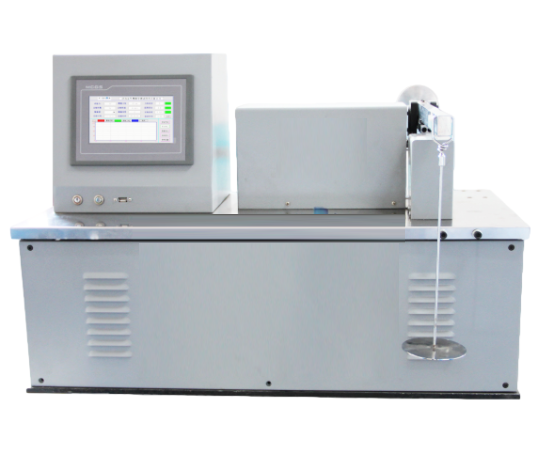

The system features a fully automatic testing process, touchscreen control, high-precision temperature management, and comprehensive data storage capabilities. All temperature deviations remain well within the limits specified by national standards.

Application

This test furnace is used in coating laboratories, building material research institutes, steel structure engineering companies, fireproof coating manufacturers, and quality inspection departments. It is applicable to thermal insulation efficiency testing, fire resistance rating verification, material development, production quality control, and certification evaluation for steel structure fireproof coatings. The equipment provides reliable data for assessing coating performance under simulated fire exposure conditions.

Standards Compliance

(1) GB14907-2018 Fireproof Coatings for Steel Structures

(2) GB/T 9978-2008 Fire-Resistance Tests—Elements of Building Construction

Product Features

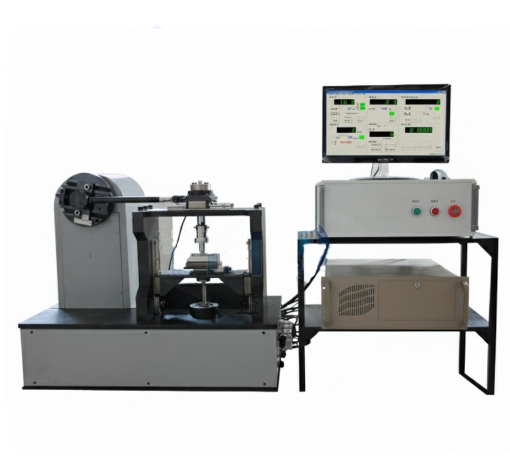

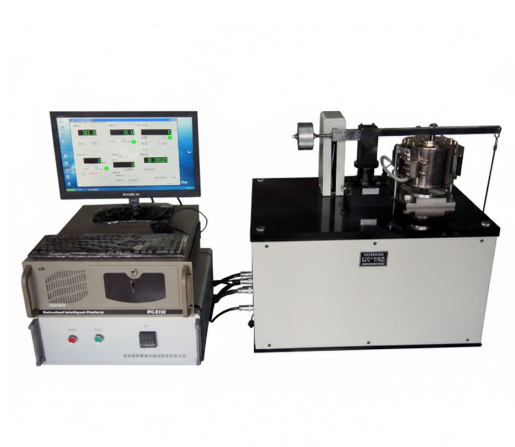

(1) Touchscreen and PC dual control; supports wireless connection. One computer can control multiple devices, and each device can connect to multiple computers.

(2) Automatic elimination of faulty thermocouples to ensure test accuracy.

(3) Fully automated test operation process from heating to cooling.

(4) Automatic plotting of temperature curves and pressure curves in real time.

(5) Automatic cooling and exhaust after test completion; anti-power-off protection mode prevents unexpected shutdown damage.

(6) Auto-ignition function in case of flameout during testing.

(7) Automatic stop when the preset temperature is reached.

(8) Storage capacity of more than 100 sets of test data.

(9) Temperature accuracy exceeds national standard requirements.

Technical Parameters

| Parameter | Unit | Value |

|---|---|---|

| Working voltage | V | AC 220 ±10%, 50 Hz |

| Power consumption | kW | 3 |

| Furnace pressure measurement range | Pa | 0–100 |

| Furnace pressure control | Pa | 20 ±3 |

| Airflow range | m³/min | 0–50 |

| Airflow accuracy | m³/min | ≤ ±0.5 |

| Fuel | – | 0# or -10# diesel |

| Test temperature programs | ℃ | 60 min: RT–925°C 120 min: RT–1050°C 180 min: RT–1115°C 240 min: RT–1150°C 300 min: RT–1180°C 360 min: RT–1210°C |

| Furnace thermocouples | pcs | 4 |

| Back-fire thermocouples | pcs | 2 |

| Back-fire temperature accuracy | ℃ | ±4 |

| Temperature control mode | – | Average control or independent control optional |

| Temperature sensors | – | Armored K-type thermocouples, Class II |

| Heating method | – | Fully automatic spray burner |

| Data storage | sets | ≥100 |

| Timing range | min | 0–360 |

| Timing accuracy | – | High-precision digital timing |

| Specimen size | mm | 500 × 500 × 6 |

| External dimensions | m | 1.6 × 1.6 × 1.6 |

Operation and Maintenance Information

(1) Supports touchscreen and PC control for easy operation and remote monitoring.

(2) Automatic heating, timing, real-time data display, and cooling ensure stable and efficient testing.

(3) Thermocouples and burner system should be regularly inspected to maintain measurement accuracy.

(4) Automatic exhaust cooling activates after the test to ensure safe operation.

(5) Regular calibration of temperature and pressure sensors is recommended for optimal performance.

(6) Maintain clean airflow passages and burner components to ensure consistent combustion and stable furnace pressure.

Leave Message Get Price