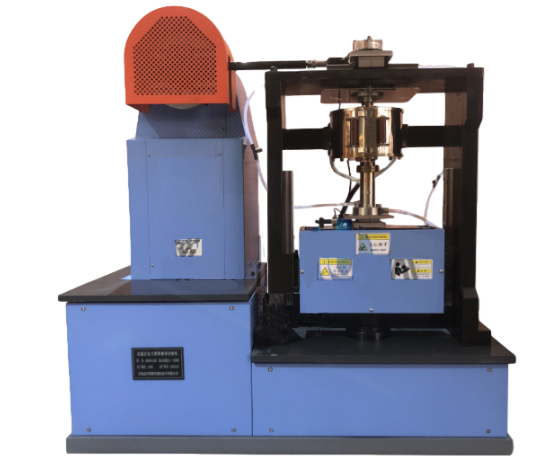

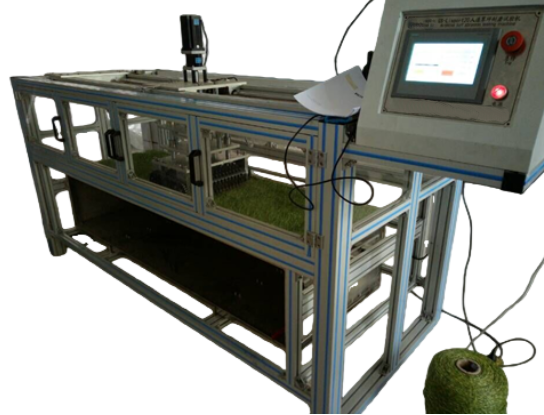

Automotive Interior Material Vertical Combustion Tester

The Automotive Interior Vertical Flame Test Apparatus is specially designed for evaluating the vertical flame characteristics of automotive interior materials in compliance with national standard GB 32086-2015. It is suitable for M3-class vehicles carrying more than 22 passengers, specifically for interior curtains, sunshades, and other hanging materials. The apparatus provides precise, repeatable measurements to ensure materials meet stringent fire safety requirements. This equipment is not suitable for buses with standing passengers.

Application Scenarios

This instrument is widely used in the automotive industry to assess the fire safety of interior hanging materials. Typical applications include:

Automotive interior safety testing

Evaluates the vertical flame spread of curtains, sunshades, and decorative hanging materials in M3-class passenger vehicles.

Quality control for interior components

Ensures all batches of interior materials meet national flame-retardant requirements before vehicle assembly.

Material development and certification

Assists manufacturers in developing new fabrics and composites with enhanced vertical flame resistance.

Regulatory compliance testing

Supports automotive OEMs in fulfilling GB 32086-2015 and European Union directives related to fire safety of specific interior materials.

Standards Compliance

Design Standard: GB 32086-2015 – Vertical flame characteristics of specific automotive interior materials

Other Standards: EU Automotive Directive 95/28/EC – Vertical flame testing of interior materials

Technical Specifications

| Item | Specification |

|---|---|

| Control System | PLC + 7-inch touchscreen |

| Ignition | Automatic Bunsen burner ignition |

| Flame Application Angle | Default 30°, optional 45° |

| Flame Height | Adjustable from 10 mm to 100 mm |

| Flame Application Time | 0.1–999.9 s, presettable, automatic timing |

| Timer Resolution | 0.1 s |

| Sample Fixture | Frame height 560 mm; parallel rods spaced 150 mm with 2 mm diameter fixing pins; positioning pillars 2 mm diameter, 20 mm height |

| Pressure Plate | U-shaped, 1 mm ±0.1 mm thick, holes to match fixture pins |

| Ventilation Hood | Cold-rolled steel, electrostatic spray coating; volume 20–110× sample fixture volume; optional airflow 0.10–0.30 m/s |

| Burner Location | Below sample, along vertical centerline; nozzle 0.18 ±0.03 mm diameter; distance from nozzle to flame tip 40 mm ±2 mm |

| Gas Type | Industrial propane, butane, or liquefied petroleum gas (user-supplied) |

| Lighting | 2 × 20 W LED spotlights |

| Touchscreen Display | 7-inch TFT, 800 × 480 resolution; RS232, CMOS/TTL interfaces; 1 GB storage; M3+FPGA architecture for zero startup time |

| Power Supply | 220 V AC ±15%, 500 W |

| Safety Features | Automatic flame retraction, real-time monitoring, robust ventilation |

FAQ

1. What materials can be tested with this apparatus?

Hanging interior fabrics, curtains, and sunshades used in M3-class passenger vehicles. It is not suitable for standing passenger buses.

2. Can the flame angle and height be adjusted?

Yes, the default flame angle is 30°, with an optional 45° setting. Flame height is continuously adjustable between 10 mm and 100 mm.

3. How is timing controlled?

Flame application and after-flame durations are automatically timed with a resolution of 0.1 s, and all data can be recorded via the touchscreen interface.

4. What type of gas is required?

Industrial propane, butane, or liquefied petroleum gas can be used. Gas supply and connections must be provided by the user.

5. Can I observe the sample during the test?

Yes, the sample is fixed on a front-facing fixture aligned with the viewing window, allowing clear observation of flame behavior during testing.

Leave Message Get Price