Horizontal & Vertical Burning Tester | GB/T 2408-2008 ANSI/UL94

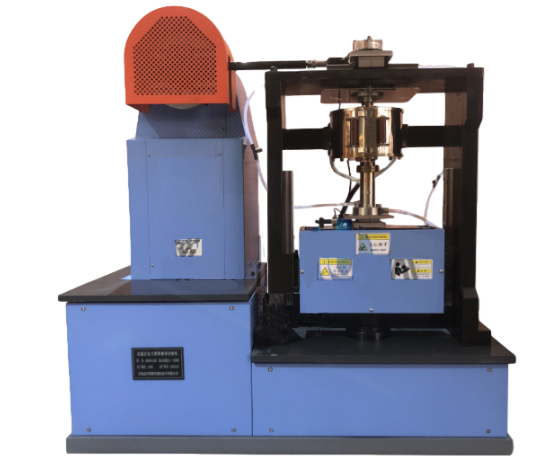

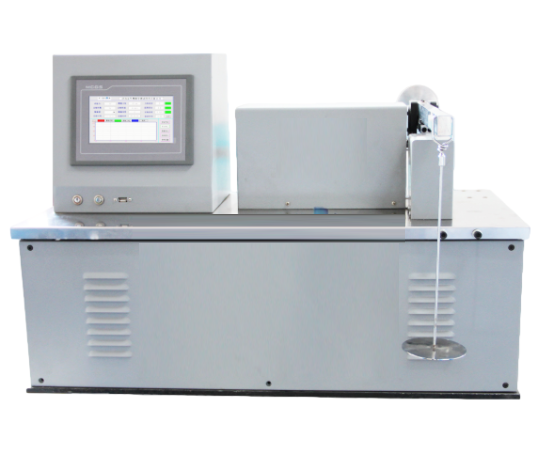

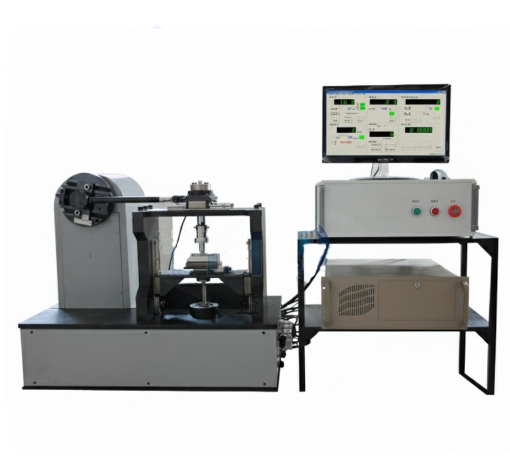

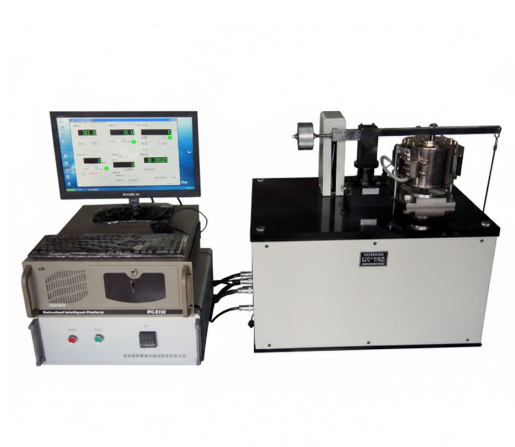

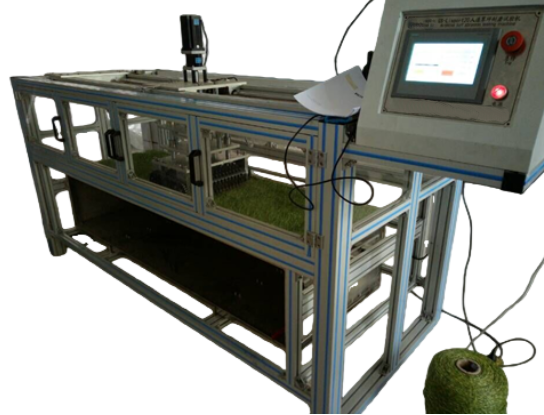

The Horizontal & Vertical Burning Tester is a high-precision laboratory instrument designed to evaluate the combustion performance of plastics and non-metallic materials under horizontal and vertical flame conditions. It is widely used in research, quality control, and industrial testing to assess flame retardancy, safety, and compliance.

Equipped with a PLC-controlled touchscreen interface, this tester automates ignition, flame application, timing, and data recording. It ensures accurate, repeatable, and efficient testing while reducing human error. The device also features adjustable flame height, temperature, and gas flow, making it suitable for a wide range of materials and testing scenarios.

Applications

The Horizontal & Vertical Burning Tester is ideal for:

Plastics and Rubber Industry: Assessing flame retardancy of plastic components, rubber sheets, and non-metallic composites.

Electronics and Electrical Equipment: Testing housings, panels, and insulation materials for UL, IEC, and GJB compliance.

Consumer Products: Evaluating materials used in furniture, toys, household appliances, and automotive interiors.

Research & Development: Material testing in universities, laboratories, and R&D departments.

Quality Control: Ensuring production materials meet fire safety standards before market release.

Standards Compliance

The tester meets international and national fire testing standards, including:

GB/T 2408-2008: Plastics – Horizontal and vertical burning methods

ANSI/UL94-2006: Standard for flammability of plastic materials

GB/T 10707-2008 / GB/T 13488: Rubber combustion performance – Vertical burning method

GJB360B-2009: Electronic and electrical components testing

GB/T 5169.16-2008

IEC 60950-1: Safety of information technology equipment

Product Parameters

| Parameter | Specification |

|---|---|

| Ambient Temperature | Room temperature – 40°C |

| Relative Humidity | ≤75% |

| Power Supply | 220V ±10%, 50Hz, 150W |

| Flame Tube Inner Diameter | 9.5 mm ±0.5 mm |

| Timer Range | 0–999.9 s |

| Flame Application Time | 0–999.9 s (adjustable) |

| After-Flame Time | 0–999.9 s |

| After-Glow Time | 0–999.9 s |

| Combustion Angle | 0°, 20°, 45° selectable |

| Flame Height | 20–130 mm (adjustable) |

| Flame Temperature | 100–1000°C (adjustable) |

| Gas Flow Rate | 0–1000 ml/min (adjustable) |

| Test Chamber Volume | >0.5 m³ (customizable up to 1 m³) |

| Dimensions | 1160 × 600 × 1310 mm (W×D×H) |

| Net Weight | ~100 kg |

| Optional Features | Flame calibration device, gas leak alarm, anti-backflow ventilation system |

FAQ

Q1: What types of materials can be tested?

A1: Plastics, rubber, non-metallic composites, and electrical insulation materials.

Q2: Which standards does this tester comply with?

A2: GB/T 2408-2008, ANSI/UL94-2006, GB/T 10707-2008, GJB360B-2009, GB/T 5169.16-2008, IEC 60950-1.

Q3: Can the flame height, temperature, and gas flow be adjusted?

A3: Yes, all parameters are fully adjustable to meet various testing protocols.

Q4: How does automation improve testing efficiency?

A4: The PLC-controlled touchscreen automates ignition, flame application, timing, and data recording, ensuring repeatable and accurate results.

Q5: Is the device safe for lab operators?

A5: Yes, with automatic flame retraction, optional gas cutoff, anti-backflow ventilation, and optional gas leak alarms, the tester ensures operator safety.

Leave Message Get Price