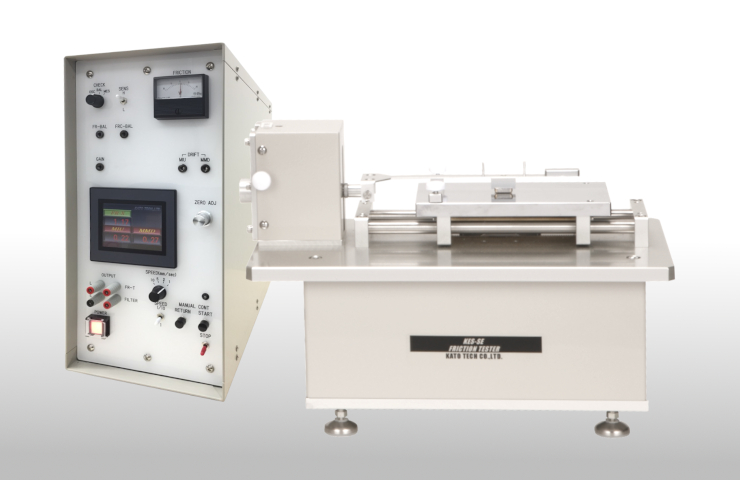

Scott Flex Tester

1. Product Introduction & Applications

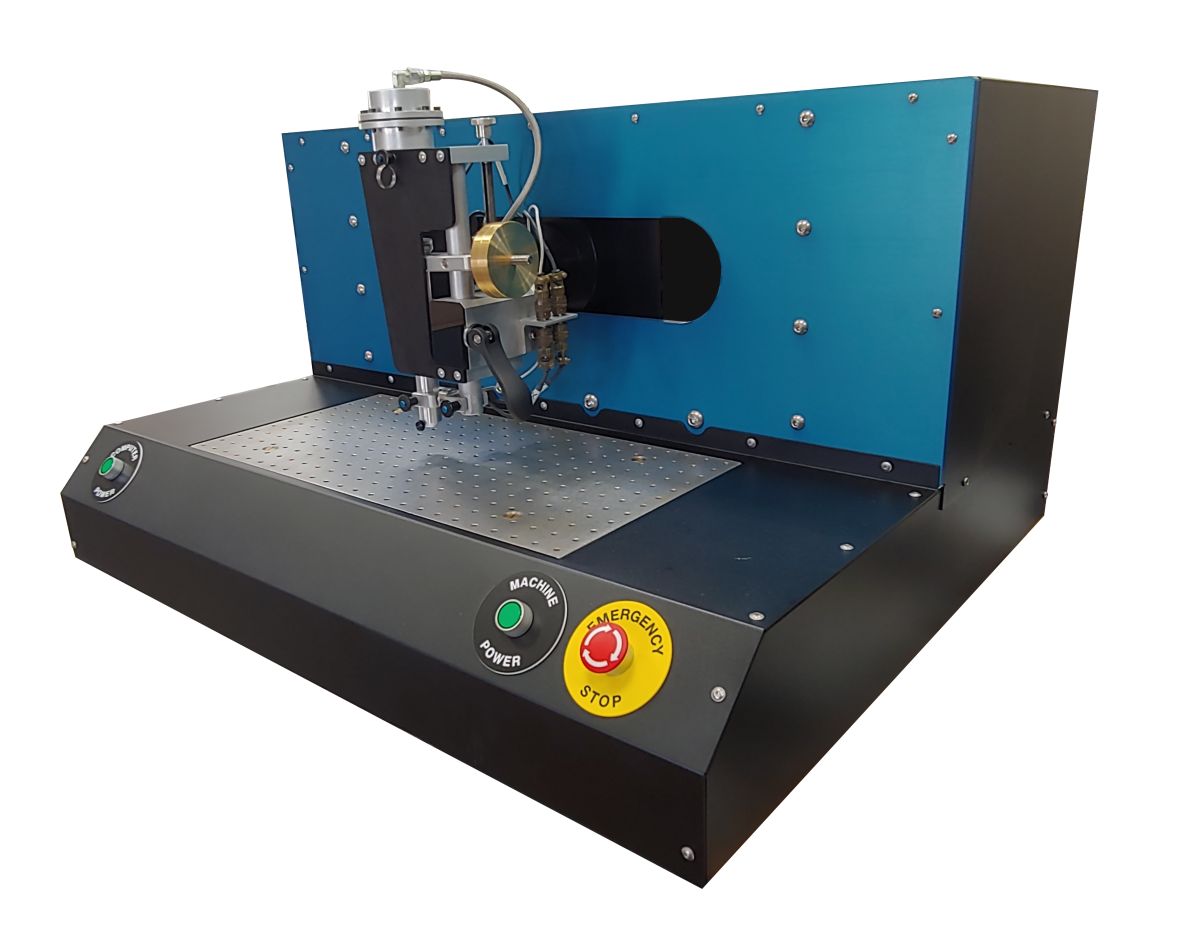

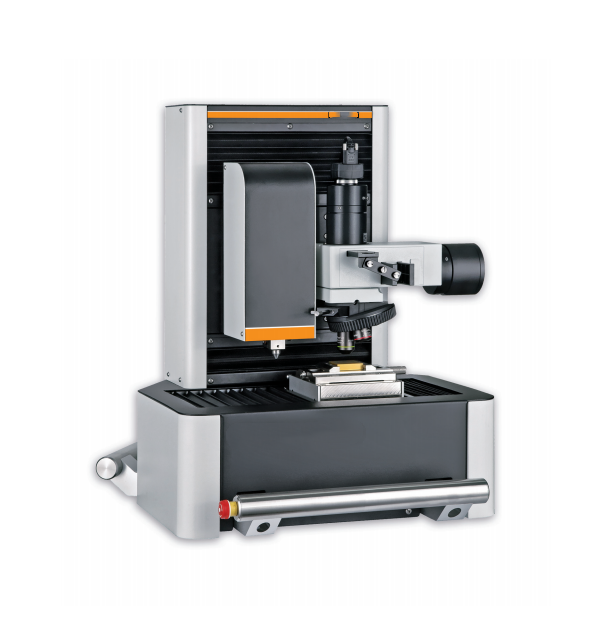

The Scott Flex Tester is designed to evaluate the resistance of flexible materials to repeated back-and-forth bending or kneading. It is widely used in quality control, research, and material development to assess durability and fatigue performance.

Key Applications:

Testing natural and artificial leather for flexing and kneading resistance.

Assessing woven fabrics and other flexible sheet materials.

Determining cycles to failure or material degradation after a set number of flexing cycles.

Supporting R&D for material durability and product development.

Working Principle:

One end of the sample is fixed in the left fixture, the other end in the right fixture. The tester applies a specified stroke, pressure, and number of cycles to flex the material. After testing, the degree of damage or wear is evaluated objectively.

2. Conformity Standards

The Scott Flex Tester meets national and international standards for flexing and kneading resistance:

GB/T 8948-2008 — Leather flexing resistance test

JIS L1096 — Standard methods for leather testing

K6404 / ASO M403 — Industry-specific flexing/abrasion test standards

These standards ensure reproducible, reliable, and globally recognized test results.

3. Technical Parameters

| Parameter | Specification |

|---|---|

| Specimen Load | 200 – 2000 g (brick-to-brick) |

| Clamp Width | 45 mm |

| Clamp Spacing | ~50 mm (adjustable) |

| Test Speed | 120 times/min |

| Test Stroke | ~60 mm (adjustable) |

| Power Supply | 220 V, 50 Hz |

| Machine Dimensions (W×D×H) | 450 × 370 × 500 mm |

| Machine Weight | 60 kg |

Additional Configuration:

Standard specimen laser cutter

Product manual and CNAS-accredited calibration report

4. FAQ

Q1: What materials can be tested?

A1: Natural leather, artificial leather, woven fabrics, and other flexible sheet materials.

Q2: Can the test stroke and number of cycles be adjusted?

A2: Yes, both the flexing stroke and number of cycles can be precisely set according to testing requirements.

Q3: How is the applied pressure controlled?

A3: The tester allows setting an appropriate pressure on the sample during testing, ensuring consistent and reproducible results.

Q4: How is damage assessed?

A4: After a set number of flexing cycles, the sample is visually inspected and evaluated for cracking, deformation, or other material damage.

Q5: Is this tester suitable for high-throughput testing?

A5: Yes, it can include multiple testing stations to evaluate several samples simultaneously, improving efficiency.

Leave Message Get Price