Application of Multi-functional Scratch Resistance Tester T108

A manufacturer of interior components supplies plastic trims, coated decorative panels, and textile materials to multiple OEM customers. The company operates an internal materials laboratory responsible for abrasion resistance, scratch resistance, and surface durability verification of incoming materials and finished products.

Testing activities must comply with international and automotive industry standards such as ISO 1518, ASTM F2496, and GME 60248, while also supporting internal quality control and research and development.

Challenges Faced by the Customer

Prior to equipment upgrade, the customer experienced several technical and operational challenges:

(1) Existing abrasion testers offered limited adjustment of stroke length, speed, and load, making it difficult to simulate real service conditions for different interior components;

(2) Single-station testing resulted in low laboratory efficiency and increased test turnaround time;

(3) Inconsistent load application led to poor repeatability of scratch and abrasion test results;

(4) Manual control and limited programmability increased the risk of operator-dependent variation;

(5) The laboratory required a single testing platform capable of accommodating different abrasive heads and test methods to support multiple standards.

Implemented Solution

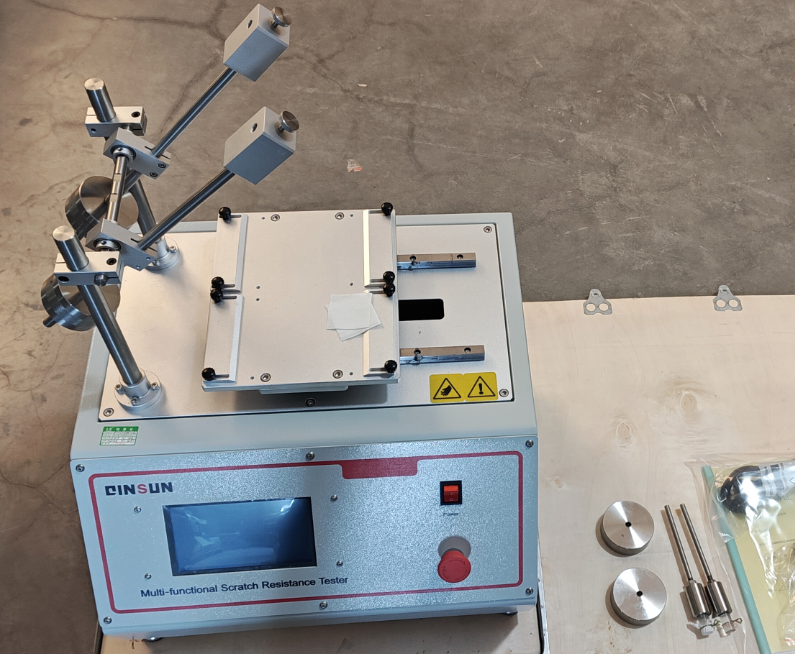

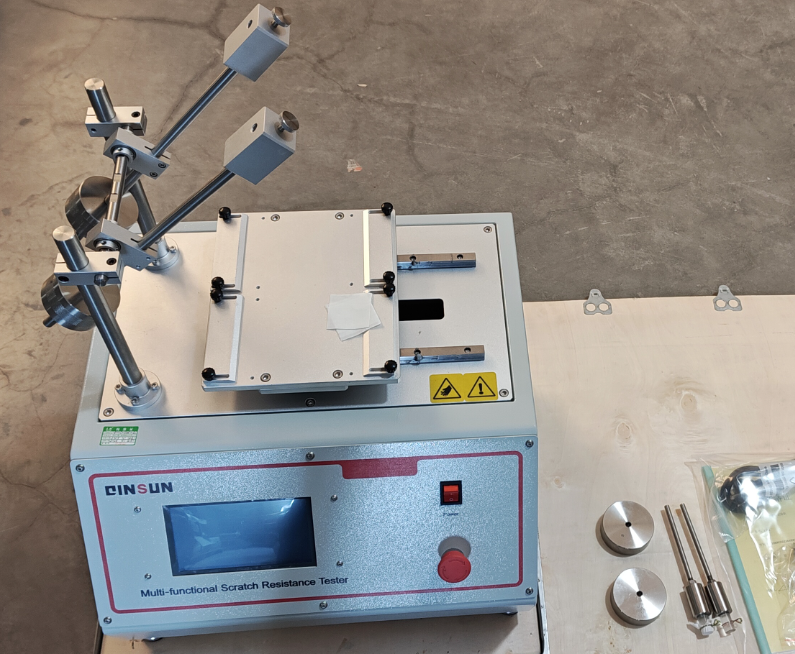

To address these issues, the customer introduced the Multi-functional Scratch Resistance Tester (Reciprocating Abrasion Tester) as a core instrument for surface durability evaluation.

The tester uses a controlled reciprocating motion with adjustable stroke range and speed, combined with a lever balance load application system. By programming test parameters through the LCD control system, the laboratory was able to standardize abrasion and scratch testing procedures for plastics, coatings, and textile materials in accordance with relevant international and automotive standards.

Product Advantages in Application

(1) Wide Parameter Adjustability

The adjustable stroke range (6–120 mm) and stepless speed control (1–100 cycles/min) allow simulation of various real-use friction conditions across different materials.

(2) Stable and Accurate Load Control

The lever balance load application principle ensures consistent and repeatable force during testing, improving result reliability.

(3) High Testing Efficiency

Dual independent workstations enable simultaneous testing of two specimens, significantly reducing total test time.

(4) Programmable Control System

The LCD-based control system allows precise setting of speed, test cycles, and parameters, minimizing operator influence and improving repeatability.

(5) Multi-standard Compatibility

Interchangeable friction heads and abrasive media support compliance with ISO, ASTM, and automotive industry standards on a single platform.

Application Results

After implementation, the customer achieved measurable improvements:

(1) Improved consistency and repeatability of scratch and abrasion test results;

(2) Increased laboratory throughput due to dual-station operation;

(3) Reduced operator-dependent variation through programmable testing;

(4) Enhanced capability to support OEM audits and standard compliance testing;

(5) More efficient material evaluation during product development and quality control stages.

Customer Feedback

“The multi-functional scratch resistance tester provides stable motion, accurate load control, and excellent repeatability. The dual-station design and programmable control significantly improved our testing efficiency. The system fully meets our requirements for ISO, ASTM, and automotive standard compliance and has become a key instrument in our materials laboratory.”

Leave Message Get Price