What is the difference between conical and parallel twin-screw extruders?

Similarities:

Both feature a conveying mechanism that forces plastic forward, excellent mixing, plasticizing, and dehydration capabilities, and offer essentially the same adaptability to materials and plastic product molding processes.

What is a twin-screw extruder?

Twin-screw extruders represent a technology. Twin-screw extruders are an advanced version of screw extruders. These machines are used in a variety of industries, including food, plastics, and rubber. Twin-screw extruders use two parallel-rotating screws to melt, shape, and mix materials. This differs from the operation of conical twin-screw extruders, which rotate in a single direction. A significant advantage of twin-screw extruders over single-screw extruders is their increased mixing capacity and improved control of process parameters, making them widely applicable in polymer processing, compounding, and extrusion technologies. Twin-screw extruders are widely used due to their wide range of processable materials and excellent control over processing conditions.

Working Principle

Twin-screw extruders are advanced machines used to manufacture a variety of plastic films, sheets, and other extruded products. A twin-screw extruder consists of two intermeshing screws within a rotating barrel, which controls the kneading, melting, and shaping of the polymer material. The basic operating principle of a twin-screw extruder can be simplified as follows:

Feeding: Polymer feed in the form of pellets or powder is fed into the extruder through a hopper. The rotating screw then propels the material toward the processing zone.

Melting and Mixing: The material to be processed is conveyed through the barrel, which contains a melting zone equipped with a heating element. The screw rotates along the barrel, mixing the molten polymer and raising its temperature. The kneading and interlocking action of the screws allows for any mechanical movement that achieves the desired composition and complete melting of all polymer components.

Pressure Buildup: Due to the continuous rotation and interaction of the screws, a cavity is formed within the screws. It can be noted that the pressure of the molten polymer during its shaping process is released through a continuous pressure relief channel, which continuously expands. This means that the applied pressure ensures a uniform distribution of the mixed material.

Shaping and Cooling: The heated end of the barrel forces the extruded polymer through a die, where it solidifies and forms the desired shape. Air or water cooling is used to cool and solidify the extrudate.

Advantages

Improved Melt Quality: The conical extruder head helps generate higher pressure inside the extruder, resulting in better melt quality and increased processing capacity, highlighting the uniqueness of the conical screw design compared to parallel screw systems. This feature is particularly beneficial for materials that can only be extruded at high pressures.

Wide Melt Product Range: The reduced diameter of the conical twin screw increases the extruder's melting capacity. Therefore, longer conical twin screws can produce a wide range of materials with varying melt viscosities.

Reduced Blade Wear: The conical twin screw design incorporates a self-cleaning feature, resulting in a uniform and clean extrudate. This minimizes the potential for material degradation, thereby improving product quality.

Inserted Material Properties: The adaptability of the conical twin screw allows for unique properties to be developed for the inserted material. For example, by controlling various processing parameters and modifying the screw configuration, products with desired characteristics and performance attributes can be extruded.

Applications in Various Industries: Conical twin-screw extruders are used in the packaging and construction industries, as well as the automotive industry. This type of extruder is versatile and can be used to extrude a wide variety of products.

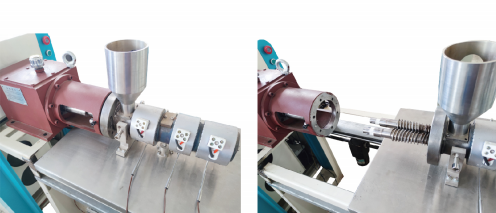

Parallel Twin-Screw Extruder

Due to the limited center-to-center distance between the two screws, the space available in the transmission gearbox for the radial and thrust bearings supporting the two output shafts, as well as the associated transmission gears, is very limited. Despite the designers' meticulous planning, they were unable to overcome the bearing load capacity, the small module and diameter of the gears, and the small tail diameter of the two screws, resulting in poor torque resistance.

Low output torque and poor load resistance are significant drawbacks of parallel twin-screw extruders. However, the flexibility of the aspect ratio is an advantage of parallel twin-screws. The aspect ratio can be increased or decreased to suit the requirements of plastic processing, depending on the molding conditions. This expands the parallel twin-screw's application range, something that conical twin-screw extruders struggle to achieve.

Applications

Parallel twin-screw extruders are widely used in plasticizing and molding. In this context, the mixing screw effectively completes the task of thoroughly mixing all materials into a homogeneous, miscible mixture. This further enables them to be used in various plastics processes, including the manufacture of PVC pipe. A suitable self-locking mechanism allows the extruder to control parameters, including temperature, thereby improving production efficiency.

By improving heat transfer and controlling the extrusion process, parallel twin-screw extruders enable manufacturers to produce consistently high-quality and high-performance PVC pipe suitable for a wide range of applications.

Conical vs. Parallel Twin-Screw Extruder Comparison

| Comparison | Conical Twin-Screw Extruder | Parallel Twin-Screw Extruder |

|---|---|---|

| Screw Geometry | The screw diameter tapers gradually from the feed section to the extrusion section, forming a tapered shape. | The screw maintains a consistent diameter throughout its entire length, creating a cylindrical shape. |

| Structural Strength and Torque | The large screw tail diameter provides high torsional strength, high output torque, and strong load-bearing capacity. | Due to limited drive box space, a small screw tail diameter results in poor torsional strength, low output torque, and significant load-bearing capacity drawbacks. |

| Long-Term Flexibility | The length-to-diameter ratio is difficult to adjust, resulting in limited flexibility. | The ability to adjust the length-to-diameter ratio to meet process requirements offers advantages in flexibility and expands the range of applications. |

| Performance | Excellent self-cleaning properties, enabling higher die pressures and excellent melt quality, making it suitable for high-pressure extrusion. | Strong mixing capacity, excellent heat transfer and control, and more uniform mixing. |

| Applicable Materials | This product can process a wide range of materials with widely varying melt viscosities, offering a wide range of applications. | It is particularly well-suited for complex formulations and materials requiring highly uniform mixing.。 |

| Main Applications | It is widely used in the packaging, construction, automotive, and other industries. | It is particularly well-suited for the production of plastic products such as PVC pipes, which require thorough plasticization and mixing. |

FAQ

Q1: What is the difference between parallel twin-screw extruders and conical twin-screw extruders?

A: The primary difference between parallel twin-screw extruders and conical twin-screw extruders lies in the screw configuration. Conical twin-screw extruders consist of two twisted screws, each narrower at the top than at the bottom, facing the barrel where the raw material is placed. This is a design feature of parallel twin-screw extruders. It can affect the shape and direction of the extrudate, as well as the efficiency of the performance.

Q2: What is the difference in screw section length between parallel twin-screw extruders and conical twin-screw extruders?

A: In parallel-screw extruders, screws with a constant diameter are typically used. On the other hand, in a turbo or conical twin-screw extruder, the screw's length may be affected by its tapered shape, which tapers gradually from a small diameter to a large diameter. This contrasts with the design of a parallel twin-screw extruder, which processes uniform cross-sectional shapes and forms.

Q3: What role do the two shafts of a conical twin-screw extruder play in operation?

A: The two shafts of a conical twin-screw extruder provide ample mixing and shearing of the material as it passes through the extruder. Due to its two screw shafts, the conical design offers a unique approach to handling materials with varying properties, thus contributing to the mixing and compounding of materials during plastics processing.

Q4: What are the advantages of a twin-screw extruder over a single-screw extruder?

A: Twin-screw extruders, as well as separable parallel and conical screw types, offer enhanced mixing, shearing, and compounding compared to single-screw configurations. They offer relatively better and more efficient material handling, making them more useful for processing complex mixtures and when the specific properties of a particular material are crucial.

Q5: How does the screw diameter ratio affect the operation of a parallel twin-screw extruder?

A: Regarding shear and folding, the screw diameter ratio of a parallel twin-screw extruder is a crucial factor. As the diameter ratio increases, the area available for mixing also increases; thus, the extruder's mixing and compounding characteristics can be further improved, making it suitable for high-volume applications.

2025-10-23 13:27