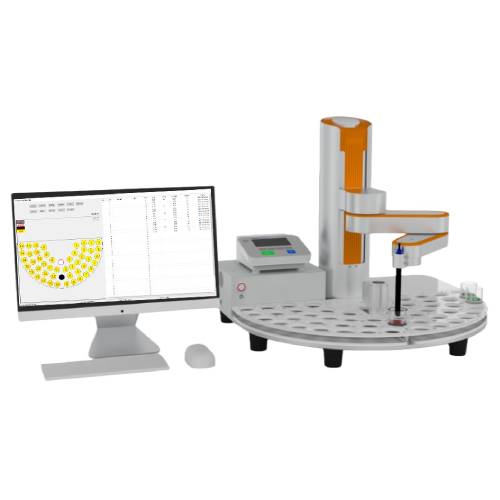

Glove Thermal Insulation Tester

The Glove Thermal Insulation Tester is a precision instrument designed to evaluate the thermal insulation performance of glove materials when exposed to high temperatures. By measuring the temperature rise on the glove surface during controlled contact with a heated brass cylinder, the system provides accurate, repeatable data to assess the protective capabilities of heat-resistant gloves in compliance with international standards.

Application

The tester is primarily used in the following scenarios:

Evaluating thermal resistance of household and industrial gloves

Assessing materials used in automotive, kitchen, and industrial safety gloves

Supporting R&D and quality control departments for heat-protective materials

Ensuring compliance with manufacturing specifications and safety regulations

Standards

The tester complies with and supports testing according to:

BS 6526:2002 – Household Oven Gloves Specification and Test Methods

ISO 12127 – Protective Gloves for Thermal Hazards (Reference Method)

EN 407 – Protective Gloves Against Thermal Risks

ASTM F1060 – Standard Test Method for Thermal Insulation of Materials

ISO 188 – Rubber, Vulcanized or Thermoplastic – Accelerated Ageing and Heat Resistance

Parameters

| Parameter | Specification |

|---|---|

| Sample Size | Diameter 70 mm |

| Temperature Range | Room Temp +5°C to 180°C |

| Temperature Accuracy | ±0.5°C |

| Temperature Resolution | 0.1°C |

| Polyethylene Sample Mounting Plate | 120 × 120 × 25 mm |

| Mounting Plate Sensor Range | 0–260°C, ±0.1% |

| Heating Block Sensor Range | 0–260°C, ±0.1% |

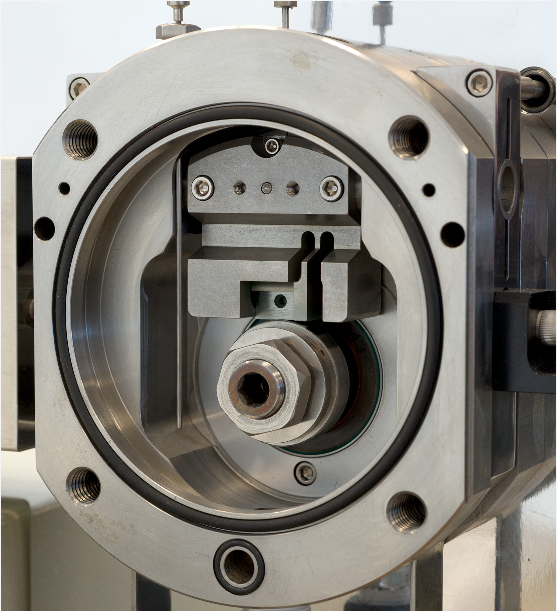

| Brass Cylinder Weight | 3000 ±10 g |

| Brass Cylinder Dimensions | Small end Φ32 ±0.02 mm H20 ±0.05 mm; Large end Φ76 ±0.02 mm H74 ±0.05 mm |

| Sensor Detection Point | 2.5 mm ±0.05 mm from cylinder base |

| Cylinder Drop Speed | 25 mm/s (adjustable 1–60 mm/s) |

| Cylinder Return Speed | 25 mm/s (adjustable 1–60 mm/s) |

| Distance from Cylinder to Sample | 100 mm ±0.5 mm |

| Polyethylene Protective Plate | 200 × 250 × 15 mm |

| Protective Plate Distance to Sample Surface | 50 mm |

| Protective Plate Movement Speed | 80 mm/s |

| Time Measurement Range | 0–99999.9 s |

| Power Supply | AC 220V, 50Hz |

| Dimensions (L×W×H) | 540 × 380 × 500 mm |

| Total Weight | 40 kg |

Features

Color touchscreen with Chinese/English interface and menu-driven operation

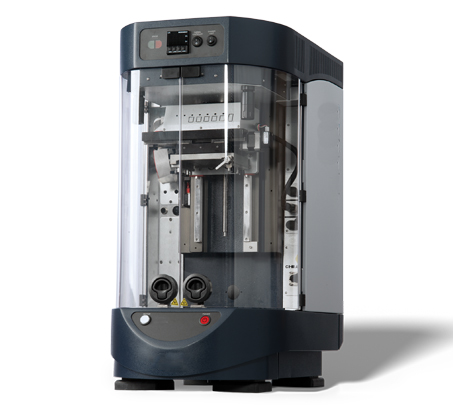

Core control via STMicroelectronics 32-bit multifunction mainboard with 16-bit high-precision AD temperature acquisition

Servo motor and servo controller for precise motion control

Real-time data display on connected PC, with automatic curve plotting

Automatic generation of test reports

Brass cylinder drops under gravity for controlled contact

Automatic cylinder return mechanism

Automatic movement and return of thermal protective plate

High-precision Omega sensors and transmitters for accurate temperature measurement

Accessories

Heated brass cylinder with sensor

Polyethylene sample mounting plate

Thermal protective plate

Servo motor and controller

Touchscreen HMI interface

PC interface for curve display and data logging

Temperature sensors and transmitters

Test Procedures

Preparation

Sample Preparation: Fix the glove onto the test fixture, ensuring the sample diameter meets the standard (typically 70 mm).

Equipment Check: Verify power supply, sensors, and heating elements are functioning properly.

Operation

Place Sample: Position the glove on the polyethylene mounting plate equipped with thermocouples connected to the temperature recording device.

Heating Test: Lower the preheated brass cylinder onto the sample and measure the temperature rise over a set duration.

Record Data: Monitor and record the glove’s internal temperature in real-time to calculate thermal insulation performance.

Precautions

Safety: Ensure operators maintain a safe distance from high-temperature components to prevent burns.

Equipment Maintenance: Regularly inspect sensors and heating devices to maintain test accuracy and reliability.

Maintenance Information

Clean thermocouples, sensors, and brass surfaces regularly to prevent measurement errors.

Inspect servo motors and moving parts monthly for smooth operation.

Verify calibration of sensors periodically to ensure accurate temperature readings.

Check the HMI and PC interface functionality to maintain data integrity.

Ensure protective plates and cylinders move freely without obstruction.

FAQs

1. What is the purpose of the Glove Thermal Insulation Tester?

The Glove Thermal Insulation Tester is a precision instrument designed to evaluate the thermal insulation performance of gloves when exposed to high temperatures. By using a heated brass cylinder and accurate temperature sensors, it measures how fast the glove surface temperature rises. The data collected is repeatable and reliable, allowing manufacturers and R&D teams to assess the protective capabilities of heat-resistant gloves in household, industrial, automotive, and kitchen applications. This helps ensure compliance with international standards and safety regulations.

2. How does the tester operate to measure glove thermal insulation?

The test involves placing a glove sample on a polyethylene mounting plate equipped with thermocouples. A preheated brass cylinder is then dropped onto the sample under controlled gravity, and the temperature rise is recorded in real time. The system uses high-precision Omega sensors and transmitters to measure temperatures accurately. The cylinder automatically returns, and the thermal protective plate moves to maintain safety. Real-time data display and automatic curve plotting on a connected PC allow operators to generate detailed test reports for evaluation.

3. Which gloves and materials can be tested with this system?

The tester is suitable for evaluating household oven gloves, industrial gloves, automotive gloves, and kitchen gloves. It can assess materials used in heat-protective applications across various industries, supporting both R&D and quality control departments. By simulating real thermal exposure, it ensures that gloves meet required manufacturing specifications, verify thermal resistance, and comply with international standards such as EN 407. ISO 12127. and ASTM F1060.

4. What features make this tester precise and reliable?

The system uses a combination of a servo-controlled brass cylinder, high-precision Omega sensors, and a 32-bit multifunction mainboard for accurate motion and temperature control. Real-time data acquisition, automatic curve plotting, and test report generation improve operational efficiency. The system also includes automatic cylinder return, protective plate movement, and a touchscreen HMI interface with Chinese/English menus. These features ensure precise, repeatable measurements while maintaining operator safety.

Leave Message Get Price