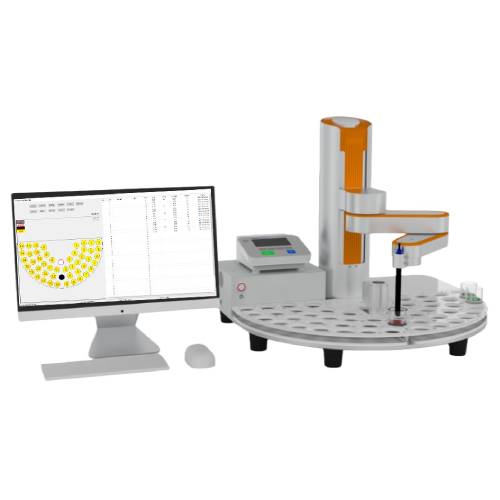

Universal Multifunction Tribology Test Machine

The Universal Multifunction Tribology Test Machine (UMT Series) is a versatile friction and wear testing system designed for comprehensive tribological evaluation in academic, research, and industrial laboratories. You can perform friction, wear, indentation, and scratch tests on a single platform while obtaining high-precision, repeatable, and reliable data.

The system supports extremely low friction coefficient measurement (down to 0.004) and enables rapid generation of Stribeck curves for in-depth lubricant and material performance analysis. Its modular architecture and interchangeable environmental chambers allow you to adapt the system to a wide range of operating conditions while maintaining compliance with major international testing standards.

Application

You can use this system for a wide variety of tribological and material performance evaluations, including:

Fundamental tribology research and surface performance characterization

Friction and wear testing of lubricating oils and greases

Tribological evaluation of metals, ceramics, polymers, composites, and coatings

Indentation and scratch testing for hardness, elastic modulus, and coating adhesion

Friction and wear testing under high temperature, low temperature, humidity, corrosive, and vacuum environments

Standardized testing in universities, research institutes, and industrial R&D laboratories

Typical tested products include lubricants, bearing materials, surface coatings, engineering plastics, ceramic components, and functional thin films.

Standards

The system is compatible with, but not limited to, the following international standards:

(1) ASTM G77 – Block-on-Ring Wear Testing

(2) ASTM G99 – Pin-on-Disk Wear Testing

(3) ASTM G132 – Ball-on-Three-Plate Wear Testing

(4) ASTM G119 – Reciprocating Sliding Wear Testing

(5) ASTM G203 – Reciprocating Wear of Materials

(6) ASTM G204 – Sliding Wear Under Controlled Conditions

(7) ASTM G206 – Oscillatory Wear Testing

(8) ASTM G133 – Linearly Reciprocating Ball-on-Flat Wear Testing

(9) ASTM G174 – Scratch Testing of Materials

(10) ASTM D3702 / ASTM D3704 / ASTM D2981 / ASTM D2509 – Lubricant and Grease Wear and EP Performance

Parameters

Motion Drive Modules

| Drive Type | Typical Applications | Speed / Frequency Range | Torque / Stroke | Applicable Standards |

|---|---|---|---|---|

| Rotary Drive | Ball-on-disk, pin-on-disk, disk-on-disk | 0.1 – 5,000 rpm | Torque up to 5 Nm | ASTM G99, ASTM G132, ASTM D3702 |

| Reciprocating Drive | Ball-on-flat, pin-on-flat, ring-on-sleeve | 0 – 60 Hz (20 Hz @ 25 mm, 40 Hz @ 12.5 mm, 60 Hz @ 2 mm) | Adjustable stroke | ASTM G119, ASTM G203, ASTM G204, ASTM G206 |

| Block-on-Ring Drive | Block-on-ring wear testing | 0.1 – 5,000 rpm | Torque up to 5 Nm | ASTM G77, ASTM D3704, ASTM D2981 |

| Linear Drive | Scratch, indentation, low-speed friction | 0.002 – 10 mm/s | Stroke up to 120 mm | ASTM G174, ASTM G133 |

Sensors and Measurement System

| Sensor Type | Range / Characteristics |

|---|---|

| 2D Force Sensors | Multiple options, measurement range from 1 mN to 2,000 N |

| Acoustic Emission Sensor | Detection of micro-cracks and friction-induced signals |

| Contact Resistance Sensor | Real-time contact state monitoring |

| Micro-Displacement Sensor | High-resolution displacement measurement for scratch and indentation tests |

Power and Interface

| Item | Specification |

|---|---|

| Power Supply | 220 V, single phase, 50/60 Hz |

| Communication Interface | USB connection |

| Control Computer | Standard PC, freely replaceable |

Features

High accuracy and repeatability: You can measure friction coefficients as low as 0.004 with excellent data consistency and rapid Stribeck curve generation.

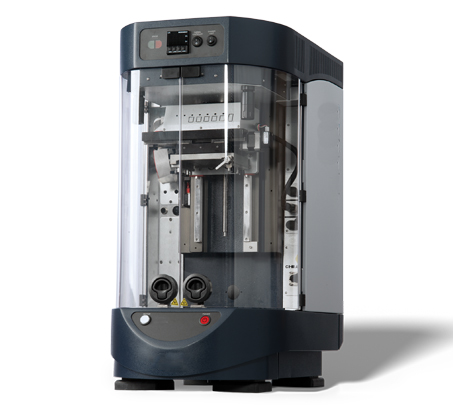

Modular configuration: Four motion drive modules and multiple environmental chambers allow hundreds of test configurations on a single platform.

Fast module recognition and replacement: Automatic identification enables module changes within 1–3 minutes.

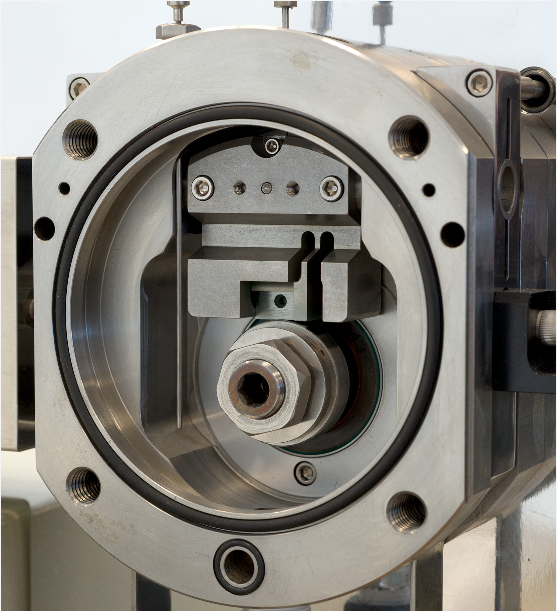

Multi-environment capability: Testing is possible under lubricated, high-temperature, low-temperature, humid, corrosive, and vacuum conditions.

Multi-sensor integration: You can simultaneously measure friction force, acoustic emission, contact resistance, and displacement with high precision.

Accessories

(1) Rotary test module for ball-on-disk and pin-on-disk configurations

(2) Reciprocating test module for ball-on-flat and pin-on-flat testing

(3) Block-on-ring test module

(4) Linear test module for scratch and indentation testing

(5) Interchangeable environmental chambers for lubrication, temperature, humidity, corrosion, and vacuum

(6) Two-dimensional force sensors

(7) Acoustic emission sensor

(8) Contact resistance sensor

(9) Micro-displacement sensor

Test Procedures

(1) Select the appropriate motion drive module and environmental chamber based on your test requirements.

(2) Install the specimens and verify proper alignment and fixture stability.

(3) Calibrate force, displacement, and auxiliary sensors as required.

(4) Set test parameters including load, speed or frequency, stroke, temperature, and environmental conditions.

(5) Start the test and monitor friction force, friction coefficient, and environmental data in real time.

(6) Upon completion, gradually unload the system, stop motion, and remove the specimens for post-test analysis.

Maintenance Information

You should periodically inspect and calibrate force and displacement sensors to maintain measurement accuracy. Motion modules and fixtures should be cleaned after testing, especially following lubricated or corrosive experiments. Environmental chambers should be checked for sealing integrity, heating elements, and temperature control performance. Regular software updates and system diagnostics are recommended to ensure long-term stability and reliability.

FAQ

(1) What is this product?

This product is a multifunction tribology test machine designed to measure friction, wear, indentation, and scratch behavior of materials under controlled mechanical and environmental conditions.

(2) What is this product used for?

You use it to evaluate material surface performance, lubricant behavior, coating durability, and wear mechanisms in laboratory research and industrial development.

(3) How does this product work?

The system applies controlled motion, load, and environmental conditions through modular drive units while integrated sensors measure friction force, wear-related signals, and displacement in real time.

(4) Why is this product important?

It allows you to obtain repeatable, standardized, and high-resolution tribological data that supports material selection, lubricant formulation, and product reliability improvement.

(5) What industries is this product suitable for?

It is suitable for automotive, aerospace, mechanical engineering, materials science, surface coating, lubricant development, and academic research laboratories.

Leave Message Get Price