Seatbelt Fabric Pilling Tester

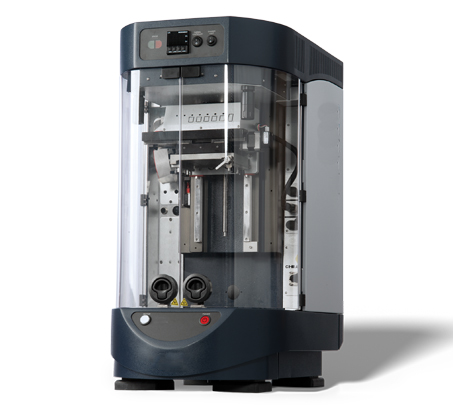

The Seatbelt Fabric Pilling Tester is designed to simulate the pilling and wear of garments caused by seatbelt friction. It is suitable for testing the frictional effects of seatbelts on textiles and evaluating the pilling changes of garments under realistic seatbelt use conditions. The system allows adjustable test speed, automated counting, and precise simulation of human movement to ensure reproducible and accurate pilling assessment.

Application

Simulating pilling and wear on garments caused by seatbelt friction

Friction testing of seatbelts against textile materials

Evaluating garment durability under realistic seatbelt use conditions

Textile performance testing in automotive and apparel industries

R&D and quality control laboratories for garments and safety equipment

Technical Parameters

| Parameter | Specification |

|---|---|

| Swing Speed | 5–60 swings/min, adjustable |

| Swing Count | 1–99,999, programmable |

| Machine Weight | 100 kg |

| Power Supply | AC 220 V, 500 W |

| Control Interface | Color touch screen, user-friendly operation |

| Drive | Servo motor for stable and reliable rotation |

Features

User-friendly control: Color touch screen with intuitive human-machine interface

Automated testing: One-button start, automatic counting, and automatic stop after test completion

Realistic simulation: Microcontroller-based control accurately simulates human movement frequency and swing times

Adjustable speed: Test speed can be varied to evaluate different effects on textile samples

Stable operation: High-precision servo motor ensures smooth and reliable rotation

Accurate pilling assessment: Simulates real-life seatbelt friction on garments for reproducible results

Test Procedures

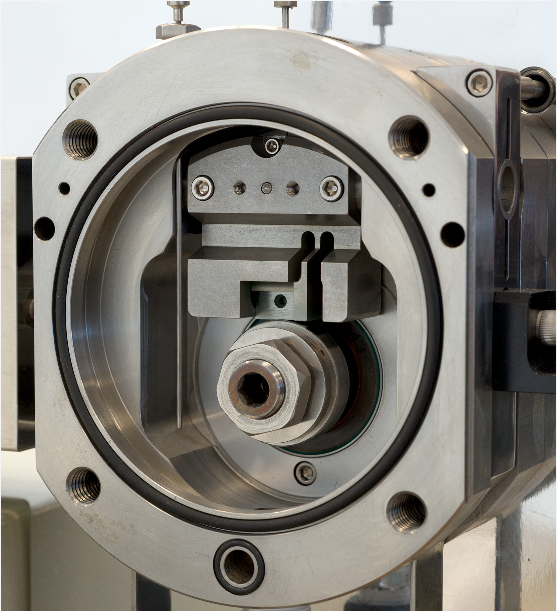

Sample Preparation: Secure textile samples onto the polyurethane tube inside the drum.

Simulation Setup: Configure swing speed and number of swings according to test requirements.

Testing: Start the machine; the system automatically performs the swinging motion while counting cycles.

Observation: After completing the set number of swings, remove the samples and compare them with standard reference samples to evaluate the pilling grade.

Data Recording: Record swing speed, number of cycles, and sample evaluation results.

Maintenance Information

Regularly clean the drum, polyurethane tube, and safety covers

Check servo motor and electronic control system for proper operation

Inspect and calibrate the touch screen and counting system periodically

Ensure power supply stability and avoid overloading

Replace worn or damaged components to maintain accuracy

FAQ

1. What is this product?

A testing machine that simulates garment pilling caused by seatbelt friction.

2. What is this product used for?

To evaluate textile pilling and frictional wear caused by seatbelt contact under realistic usage conditions.

3. Why is this product important?

Ensures accurate, reproducible simulation of seatbelt friction for quality control and R&D of garments and automotive textiles.

4. What industries is this product suitable for?

Automotive apparel, textile testing labs, garment R&D, and quality control laboratories.

5. What types of this product are available?

Seatbelt pilling testers with adjustable swing speed, programmable cycles, color touch screen, and servo motor drive.

Leave Message Get Price