Rolling Bearing Tribometer

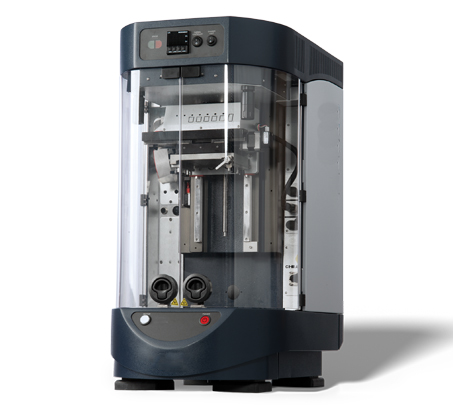

The Rolling Bearing Tribometer is a laboratory test system used to measure friction losses, temperature rise, and dynamic behavior of rolling element bearings under controlled load and speed conditions. The system is suitable for testing a wide range of rolling bearings, including axial-load and heavy-duty taper roller bearings. Two interchangeable test assemblies allow operation under low-load and high-load conditions, enabling accurate friction and durability evaluation across different bearing sizes and load classes.

Application

The Rolling Bearing Tribometer is used for the following applications and test objects:

Friction loss testing of rolling bearings, including radial, thrust, and angular contact bearings

Performance evaluation of taper roller bearings under high axial loads

Lubricant performance testing using oils and greases under controlled temperature conditions

Temperature rise and vibration monitoring of bearings at variable speeds and loads

Bearing design validation and comparative performance analysis

Quality control and durability assessment in bearing manufacturing

Research and teaching applications in tribology and mechanical engineering laboratories

Standards

The system is applicable to testing and evaluation in accordance with the following standards and guidelines:

(1) GB/T 307.1 — Rolling Bearings — Dynamic Performance Test Methods

(2) GB/T 307.2 — Rolling Bearings — Friction and Endurance Test Methods

(3) ISO 15243 — Rolling Bearings — Damage and Failure Terminology

(4) ASTM D7048 — Standard Test Method for Measurement of Bearing Friction and Lubrication Performance

(5) DIN 51819 — Lubrication and Fatigue Testing of Rolling Bearings

(6) ISO 281 — Rolling Bearings — Dynamic Load Ratings and Rating Life

(7) ISO 7628 — Measurement of Mechanical Vibration

Parameters

| Item | Low Load Assembly | High Load Assembly |

|---|---|---|

| Load range | 200 – 10,000 N | 2,000 – 40,000 N |

| Load actuation | Servo-controlled pneumatic bellows | Servo-controlled pneumatic bellows |

| Load feedback | Force transducer | Force transducer |

| Friction torque measurement | In-line torque transducer (10 Nm) | Torque arm with load cell |

| Maximum bearing outer diameter | 60 mm | 180 mm |

| Speed range | 100 – 7,500 rpm | 100 – 7,500 rpm |

| Heating power | 550 W | 550 W |

| Maximum test temperature | 150 °C | 150 °C |

| Temperature sensor | Type K thermocouple | Type K thermocouple |

| Vibration sensor | Piezoelectric, adjustable sensitivity | Piezoelectric, adjustable sensitivity |

| Load reaction path | Main shaft bearing | Bearing housing |

| Control interface | Serial communication | Serial communication |

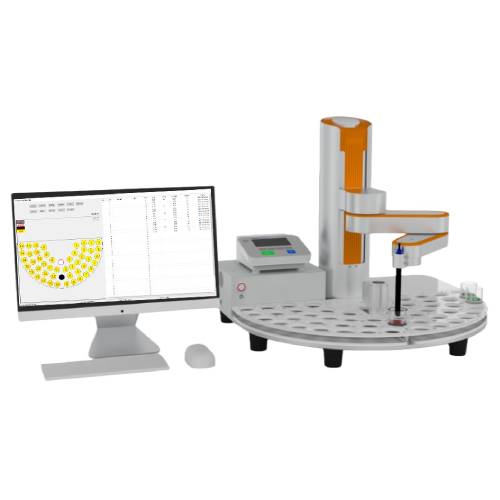

| Software interface | PC-based control and data acquisition | PC-based control and data acquisition |

| Drive motor | AC motor, 4 kW @ 1,500 rpm | AC motor, 4 kW @ 1,500 rpm |

| Power supply | 3-phase industrial supply | 3-phase industrial supply |

Features

(1) Dual load configuration supporting both low-load and high-load bearing tests

(2) High-speed capability up to 7,500 rpm for dynamic friction evaluation

(3) Accurate friction torque measurement using direct torque sensing or torque arm methods

(4) Independent load reaction design to protect the main drive shaft under high loads

(5) Integrated temperature and vibration monitoring for comprehensive bearing condition analysis

(6) Compatibility with circulating lubrication systems for oil temperature control and cooling

(7) Flexible bearing fixture design allowing testing of different bearing types and sizes

Accessories

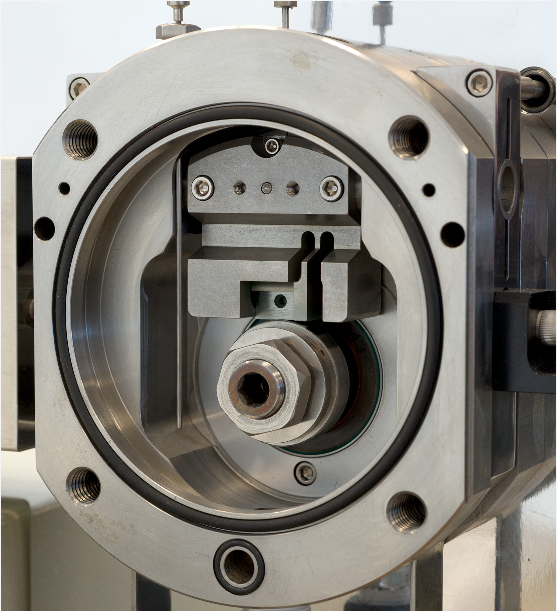

(1) Low-load bearing test assembly with self-aligning lubricant reservoir

(2) High-load bearing test assembly with reinforced bearing housing

(3) Pneumatic load actuation system with force feedback

(4) Lubrication circulation module with heating and cooling capability

(5) Bearing mounting fixtures for different bearing geometries

(6) Temperature and vibration sensors

(7) PC-based control and data acquisition software

Test Procedures

(1) Install the test bearing into the appropriate test assembly and ensure correct alignment

(2) Fill the lubricant reservoir and activate the lubrication circulation system

(3) Set test parameters including speed, load, temperature, and test duration

(4) Gradually apply the specified load using the pneumatic loading system

(5) Start the drive motor and stabilize the test conditions

(6) Record friction torque, temperature, vibration, and rotational speed continuously

(7) Monitor test conditions and stop the test if abnormal vibration or temperature rise occurs

(8) After test completion, unload the bearing and perform post-test inspection and data analysis

Maintenance Information

Regularly clean the lubricant reservoir, bearing fixtures, and seals to prevent contamination.

Inspect pneumatic components, sensors, and electrical connections periodically.

Verify calibration of torque, force, temperature, and vibration sensors at defined intervals.

Ensure proper lubrication of moving components and replace worn seals or fittings when necessary.

Disconnect electrical and pneumatic supplies before maintenance operations.

FAQ

(1) What is this product?

It is a laboratory tribometer designed to measure friction losses and operating behavior of rolling element bearings under controlled load, speed, and lubrication conditions.

(2) What is this product used for?

It is used to evaluate bearing friction, temperature rise, vibration response, and durability for research, product development, and quality control purposes.

(3) Why is this product important?

It provides quantitative data on bearing efficiency and operating stability, which is critical for optimizing bearing design, lubricant selection, and service life.

(4) What industries is this product suitable for?

It is suitable for bearing manufacturing, automotive engineering, industrial machinery, energy equipment, aerospace research, and academic laboratories.

(5) What types of this product are available?

The system supports interchangeable low-load and high-load test assemblies to accommodate different bearing sizes and load requirements.

Leave Message Get Price