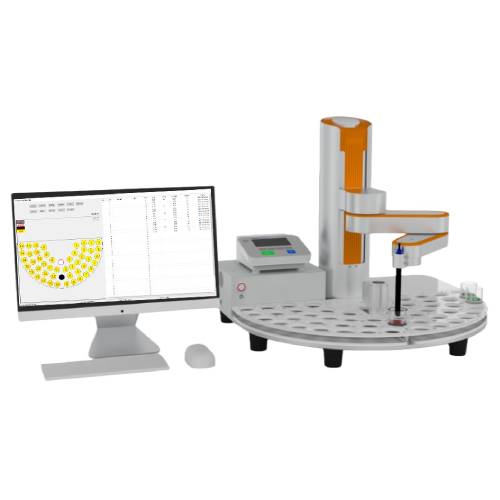

Micro-Scale Abrasion Tester

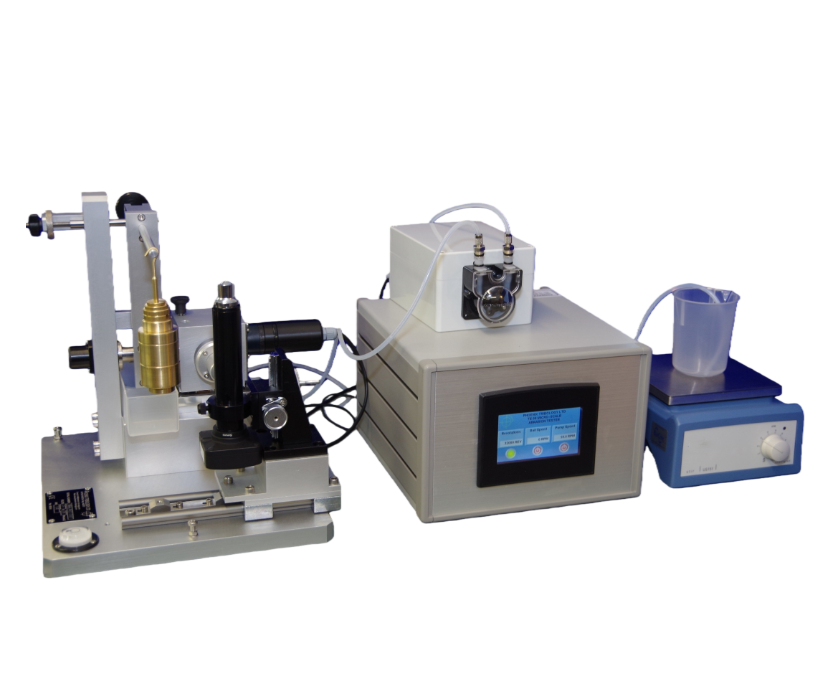

The Micro-Scale Abrasion Tester is a laboratory instrument used to evaluate abrasive wear behavior of hard coatings, soft coatings, and monolithic materials using a controlled ball-on-plate contact configuration. You can use this system to determine wear coefficients under micro-abrasion conditions and to generate controlled wear craters for accurate coating thickness measurement. The tester provides precise control of load, rotational speed, and test cycles, ensuring repeatable and standardized wear testing results.

Application

You can use this tester in the following application scenarios and test objects:

Coating wear resistance evaluation: PVD coatings, CVD coatings, thermal spray coatings, ceramic coatings

Coating thickness determination: thin film and functional coatings on metal or ceramic substrates

Material research: ceramics, metals, polymers, and surface-treated materials

Tribology studies: micro-scale abrasive wear mechanism analysis

Quality control: coating consistency verification and process validation

Academic and research laboratories: teaching experiments and wear modeling studies

Standards

BS EN 1071-6 — Advanced Technical Ceramics – Methods of Test for Ceramic Coatings – Determination of Abrasion Resistance by Micro-Abrasion Wear Test

Parameters

| Item | Specification |

|---|---|

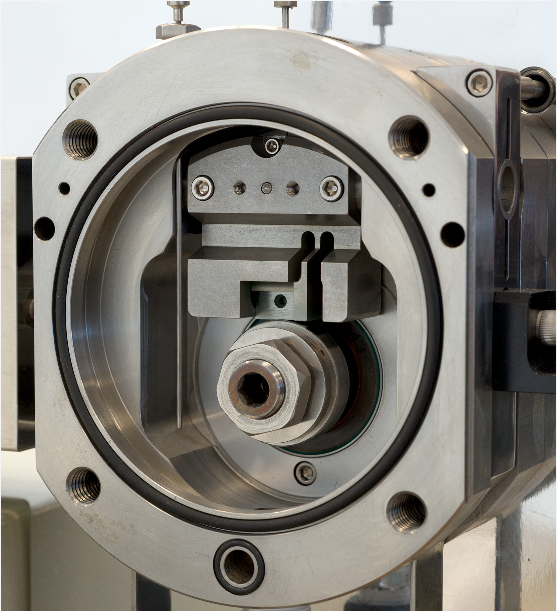

| Contact configuration | Ball-on-plate |

| Ball diameter | 25 mm |

| Ball speed range | 30 – 150 rpm |

| Load range | 0.05 – 5 N |

| Abrasive supply | Slurry-fed |

| Slurry feed rate | Up to 60 ml/hour |

| Load application | Counterbalanced beam with pivot |

| Speed control | Manual set-point via touch interface |

| Cycle measurement | Integrated revolution counter |

| Wear observation | Integrated digital microscope |

| Camera resolution | 5 MP CMOS USB camera |

| Optical magnification | ×3 and ×5 |

| Power supply | 220/240 V, single phase, 50 Hz, 120 W or 110/120 V, single phase, 60 Hz, 120 W |

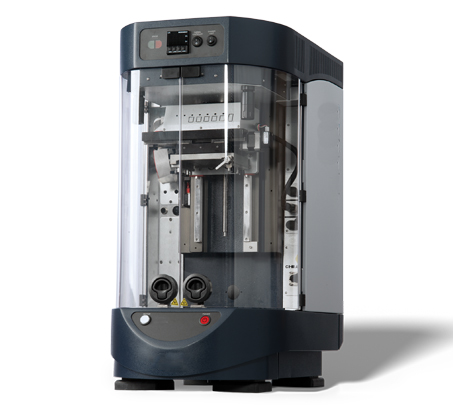

| Installation type | Bench-mounted |

| Machine dimensions | 720 × 440 × 570 mm |

| Cabinet dimensions | 530 × 420 × 320 mm |

| Net weight | 25 kg |

| Gross weight | 50 kg |

Features

Precisely defined normal load independent of friction conditions

Clamped ball design ensures accurate speed and cycle control

Wide load range without the need for changing ball sizes

Stable and repeatable abrasive slurry delivery using a peristaltic pump

Integrated digital microscope enables in-situ crater measurement

Suitable for both wear coefficient calculation and coating thickness determination

Compact bench-mounted design for laboratory environments

Accessories

(1) Standard ball specimen (25 mm diameter)

(2) Abrasive slurry delivery system

(3) Peristaltic pump with tubing

(4) Digital microscope with USB camera

(5) Waste slurry collection tray

(6) Optional laboratory magnetic stirrer for slurry agitation

(7) Optional line-contact adapter for block-on-ring configuration

Test Procedures

(1) Prepare and clean the coated or bulk material specimen

(2) Mount the specimen securely on the counterbalanced beam

(3) Install the ball specimen in the rotating shaft

(4) Set the desired load, rotational speed, and number of cycles

(5) Prepare and supply abrasive slurry to the contact zone

(6) Start the test and monitor operating parameters

(7) Periodically stop the test and observe wear craters using the digital microscope

(8) Record crater dimensions and calculate wear coefficient or coating thickness

Maintenance Information

You should regularly clean the ball, specimen holder, slurry feed lines, and waste tray to prevent contamination.

Inspect bearings, shafts, and pivot points for smooth operation.

Check the peristaltic pump tubing for wear and replace when necessary.

Calibrate speed control and optical measurement systems periodically.

Disconnect power before performing maintenance or component replacement.

FAQ

(1) What is this product?

It is a laboratory wear testing instrument used to evaluate micro-scale abrasive wear and coating thickness.

(2) What is this product used for?

You use it to determine wear coefficients of coatings and materials and to measure coating thickness through controlled crater formation.

(3) What is the working principle of this product?

A rotating ball abrades the specimen surface in the presence of an abrasive slurry, producing a measurable wear crater under a precisely controlled load.

(4) Why is this product important?

It provides a low-cost, accurate, and repeatable method for assessing coating durability and thickness without destructive sectioning.

(5) Which industries is this product suitable for?

It is suitable for surface engineering, ceramics, materials research, coating manufacturing, quality control, and academic research laboratories.

Leave Message Get Price