Multi-Purpose Friction and Wear Tester

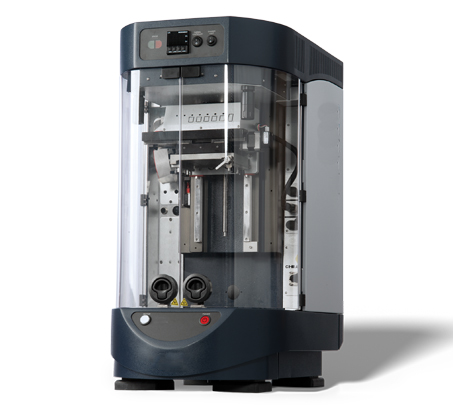

The Multi-Purpose Friction and Wear Tester is a laboratory testing system designed to evaluate friction behavior and wear performance of engineering materials under controlled contact, load, speed, and temperature conditions. You can use this instrument to conduct standardized and comparative tribological testing by simulating rolling, sliding, and mixed lubrication conditions commonly encountered in industrial applications.

Application

You can apply this tester in the following testing scenarios and product evaluations:

Bearing and transmission components: rolling bearings, sliding bearings, gear elements, and rollers

Mechanical parts: shafts, seals, valves, cams, bushings, and cylindrical components

Material research: metals, polymers, elastomers, ceramics, and composite materials

Lubricant evaluation: oils and greases under controlled temperature and load conditions

Surface engineering studies: coatings, heat-treated surfaces, and surface-modified materials

Academic and industrial laboratories: tribology research, teaching experiments, and method validation

Quality control and process optimization: material comparison, wear resistance verification, and durability assessment

Standards

GB/T 3960 — Method for Friction Testing of Metals

GB/T 3961 — Method for Wear Performance Testing of Materials

ASTM G77 — Block-on-Ring Wear Testing Method

ASTM G99 — Ball-on-Disk Wear Testing Method

ISO 7148-2 — Plain Bearings and Lubrication Friction Testing

DIN 50324 — Standard Methods for Friction and Wear Testing

Parameters

| Item | Specification |

|---|---|

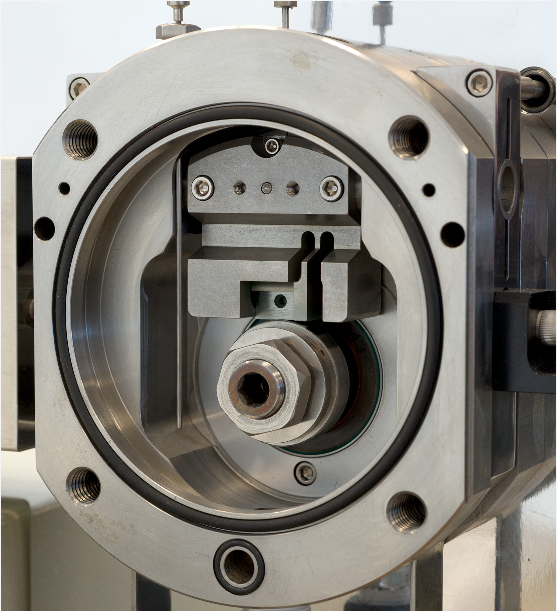

| Contact geometry | Crossed cylinder / Ball-on-cylinder / Block-on-ring / Double roller |

| Center distance | 60 mm |

| Roller diameter | 60 mm |

| Sliding specimen | 12.7 mm ball, roller, or block |

| Speed range | 30 – 850 rpm |

| Maximum sliding speed | 4.7 m/s |

| Slip ratio settings | 0.00%, 3.33%, 5.00%, 10.00%, 15.00%, 20.00% |

| Maximum friction force | 130 N |

| Friction force measurement | Strain gauge sensor |

| Load range | 50 – 750 N |

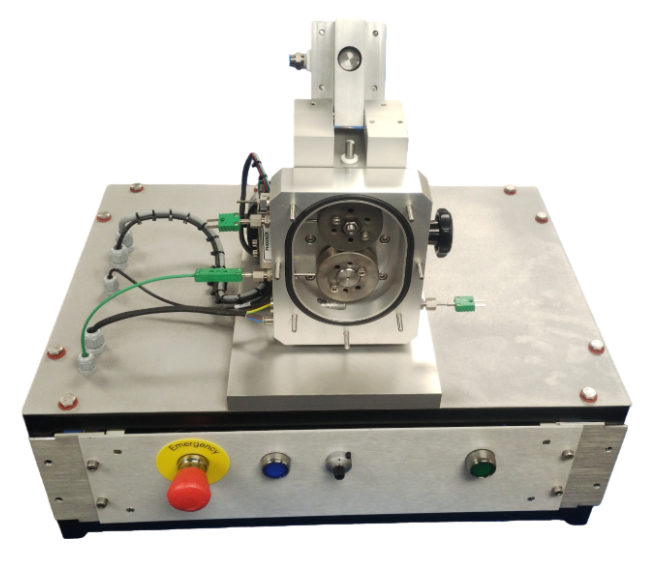

| Load actuator | Pneumatic cylinder |

| Load control | Precision pressure regulator |

| Load measurement | Pressure sensor |

| Test chamber temperature | Ambient to 150 °C |

| Heating power | 150 W |

| Temperature sensor | Type K thermocouple |

| Motor | Brushless DC servo motor, 200 W |

| Control mode | Speed, temperature, and test duration automatic; load manual |

| Measured parameters | Speed, load, friction force, temperature, revolutions, time, sliding distance, friction coefficient |

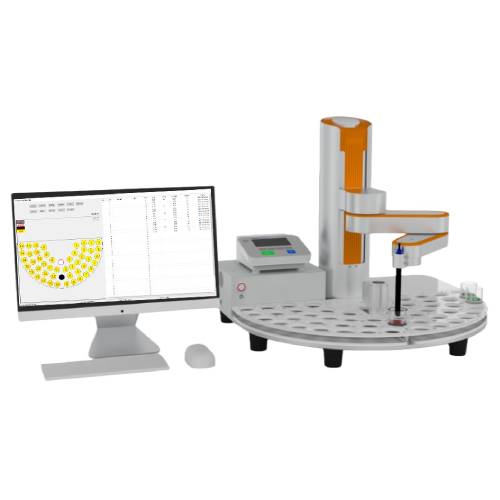

| Software interface | USB communication module |

| Power supply | 220/240 V, single phase, 50 Hz, 1.2 kW or 110/120 V, single phase, 60 Hz, 1.2 kW |

Features

Multiple contact geometries allow you to perform a wide range of tribological tests on one platform

High-precision friction force measurement ensures reliable and repeatable results

Fixed slip ratio options enable controlled simulation of rolling–sliding contact conditions

Pneumatic loading provides stable force application with fast response

Sealed and heated test chamber supports both lubricated and dry friction testing

Quick specimen replacement supports metals, polymers, elastomers, and ceramics

Integrated data acquisition enables continuous monitoring and automated testing workflows

Accessories

(1) Roller specimens with selectable material options

(2) Ball specimens with standard diameter

(3) Block specimens for block-on-ring testing

(4) Block-on-ring fixture compatible with ASTM requirements

(5) Pneumatic loading assembly with pressure regulator

(6) Heated test chamber with temperature sensor

(7) Data acquisition and control software

Test Procedures

(1) Prepare and clean all test specimens before installation

(2) Install specimens securely using the appropriate fixture

(3) Set rotational speed, slip ratio, test duration, and temperature

(4) Adjust pneumatic pressure to apply the required normal load

(5) Start the test and monitor friction force and temperature in real time

(6) Stop the test after the preset duration and safely unload the specimen

(7) Measure wear and analyze recorded data according to the selected standard

Maintenance Information

You should regularly clean the test chamber, fixtures, and specimen holders to avoid contamination.

Inspect pneumatic lines and pressure regulators for leaks and stability.

Calibrate friction and load sensors periodically to maintain measurement accuracy.

Ensure proper lubrication and cooling of moving components where required.

Disconnect power and air supply before performing maintenance or specimen replacement.

FAQ

(1) What is this product?

It is a laboratory instrument used to measure friction forces and wear behavior between contacting materials under controlled mechanical and thermal conditions.

(2) What is this product used for?

You use it to evaluate friction coefficients, wear rates, and surface durability of materials, components, and lubricants.

(3) What is the working principle of this product?

The system applies a controlled normal load and relative motion between test specimens while measuring friction force and related parameters in real time.

(4) Why is this product important?

It helps you understand material performance, optimize component design, improve lubrication selection, and reduce wear-related failures.

(5) Which industries is this product suitable for?

It is suitable for automotive, aerospace, machinery manufacturing, materials research, lubrication development, quality control, and academic research laboratories.

Leave Message Get Price