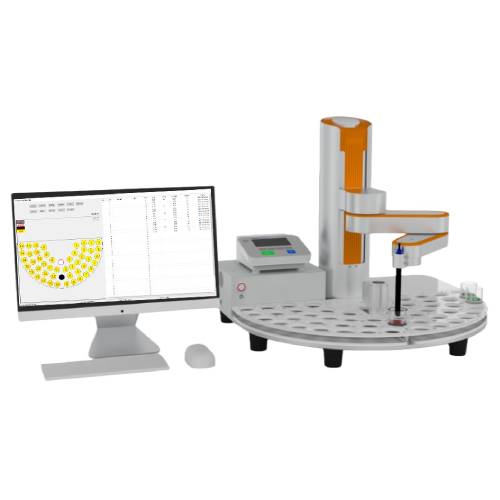

Gas Jet Erosion Rig

The Gas Jet Erosion Rig is a laboratory testing system designed to evaluate erosion wear behavior of materials and coatings subjected to high-velocity particle-laden gas flow. You use this equipment to simulate solid particle impact erosion under controlled conditions by adjusting particle velocity, mass flow rate, impingement angle, and specimen orientation. It is suitable for standardized testing and comparative analysis of metals, ceramics, polymers, and coated surfaces.

Application

You can apply the Gas Jet Erosion Rig in the following scenarios and material evaluations:

(1) Erosion resistance testing of metallic materials, ceramics, polymers, and composite materials.

(2) Performance evaluation of hard and soft coatings, including wear-resistant and protective coatings.

(3) Aerospace component erosion testing, such as turbine blades and structural parts.

(4) Wind energy component evaluation, including erosion of wind turbine blades.

(5) Industrial equipment and pipeline erosion assessment under particle-laden gas flow.

(6) Automotive coating durability and surface protection studies.

(7) Academic research and teaching in material erosion and wear mechanisms.

(8) Quality control, process optimization, and service life assessment of coated components.

Standards

You can conduct erosion tests in accordance with the following international standards:

(1) ASTM G76 – Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets

(2) DIN 50332 – Erosion Testing by Particle Jet Method

(3) ISO 20567-1 – Paints and Varnishes – Determination of Stone-Chip Resistance – Part 1

(4) ISO 20567-2 – Paints and Varnishes – Determination of Stone-Chip Resistance – Part 2

Parameters

| Parameter | Specification |

|---|---|

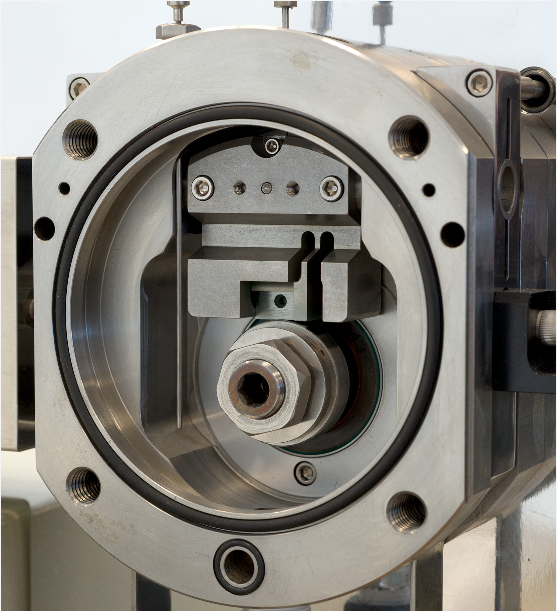

| Particle Nozzle | Inner diameter 4.7 mm, length 300 mm, stainless steel |

| Nozzle Height Adjustment | Adjustable nozzle-to-specimen distance |

| Specimen Holder | Tiltable, specimen size 50 × 50 mm |

| Particle Velocity (Standard Mode) | 25 – 80 m/s at 1.5 bar |

| Particle Velocity (Enhanced Mode) | Up to 120 m/s at 4 bar |

| Particle Mass Flow Rate | 0.2 – 2 g/min |

| Gas Heating | Optional, up to 100°C |

| Power Supply | 220/240 V, single phase, 50 Hz, 1.5 kW |

| Compressed Air (Standard Mode) | 1.5 bar, 3.5 cfm |

| Compressed Air (Enhanced Mode) | 4 bar |

| Installation Dimensions | 1000 × 1200 × 400 mm |

| Installation Type | Floor-standing |

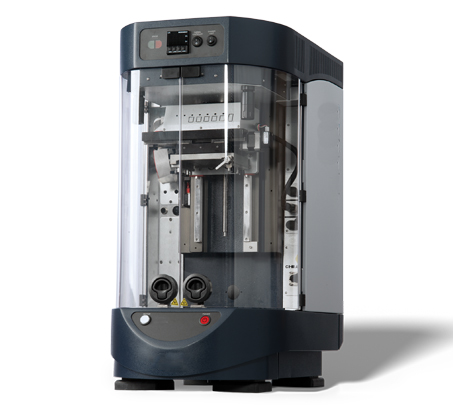

Features

(1) Large-diameter nozzle design reduces localized drilling effects and is suitable for coating and bulk material testing.

(2) Low operating pressure improves operational safety and reduces system wear.

(3) Adjustable nozzle position and tiltable specimen holder allow precise control of impact angle.

(4) Stable particle mass flow control using a grooved rotating disc combined with Venturi feeding.

(5) Suitable for a wide range of test materials and particle types.

(6) Modular construction enables quick replacement of nozzle, specimen holder, and heating unit.

(7) Optional gas heating supports erosion testing under elevated temperature conditions.

(8) Robust enclosure improves operator safety and test repeatability.

Accessories

(1) Adjustable stainless steel nozzle assembly

(2) Tiltable specimen clamping fixture for 50 × 50 mm specimens

(3) Particle feeding system with grooved disc and Venturi injector

(4) Abrasive particles selected according to test requirements

(5) Optional gas flow heating unit

(6) Compressed air connection components

(7) Safety enclosure for particle containment

Test Procedures

During testing, you accelerate solid particles using a compressed gas stream and direct them toward the specimen surface through a calibrated nozzle. The particles impact the specimen at a defined velocity and angle, producing controlled erosion wear.

You regulate erosion conditions by adjusting gas pressure, particle flow rate, nozzle distance, specimen tilt angle, and optional gas temperature. After testing, erosion wear is evaluated by mass loss measurement or surface morphology analysis to determine erosion rate and material performance.

Maintenance Information

(1) Regularly inspect the nozzle for wear or blockage and replace if necessary.

(2) Keep the particle feeding system clean to ensure stable mass flow.

(3) Verify compressed air quality to prevent moisture or contamination.

(4) Check seals, hoses, and fittings for leaks before operation.

(5) Inspect safety enclosure integrity to prevent particle escape.

(6) Calibrate particle flow and pressure settings periodically according to test standards.

FAQ

(1) What is this product?

It is a laboratory erosion testing system used to evaluate material and coating resistance to solid particle impact.

(2) What is this product used for?

You use it to simulate particle erosion under controlled gas flow conditions and compare erosion performance of different materials and coatings.

(3) What is the working principle of this product?

Solid particles are accelerated by compressed gas and directed through a nozzle to impact the specimen surface, producing erosion wear that can be quantified.

(4) Why is this product important?

It provides standardized and repeatable erosion data that supports material selection, coating development, and service life prediction.

(5) Which industries is this product suitable for?

It is suitable for aerospace, wind energy, automotive, industrial equipment, coatings development, academic research, and materials testing laboratories.

Leave Message Get Price