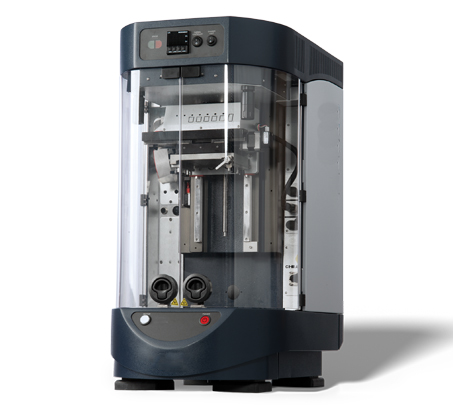

Twist Compression Tester

The Twist Compression Tester is a laboratory tribology instrument designed to evaluate friction behavior and adhesive wear properties of materials under combined axial compressive load and relative torsional motion. You use this system to perform standardized tests under dry or lubricated conditions in accordance with ASTM G223, enabling reliable comparison of material friction coefficients, friction torque, and adhesive wear performance.

Application

You can use the Twist Compression Tester for the following applications and test materials:

(1) Friction and adhesive wear evaluation of metallic materials such as carbon steels, stainless steels, non-ferrous alloys, and structural alloys.

(2) Performance assessment of surface-engineered materials including hardened layers, coated surfaces, and treated contact pairs.

(3) Tribological testing of bearing materials, sealing materials, and mechanical contact components.

(4) Comparative studies of dry versus lubricated friction behavior.

(5) Adhesive wear mechanism investigation under high contact pressure.

(6) Material screening during component design and development.

(7) Research and teaching in tribology laboratories and academic institutions.

(8) Quality evaluation and consistency verification in industrial testing laboratories.

Standards

ASTM G223 – Standard Test Method for Measuring Friction and Adhesive Wear Properties of Lubricated and Nonlubricated Materials Using the Twist Compression Test

Parameters

| Parameter | Specification |

|---|---|

| Hollow Cylinder Specimen | 25 mm outer diameter, 3 mm wall thickness |

| Flat Specimen | 40 × 40 mm, 3 mm thickness (variable) |

| Load Range | 1.5 – 50 kN |

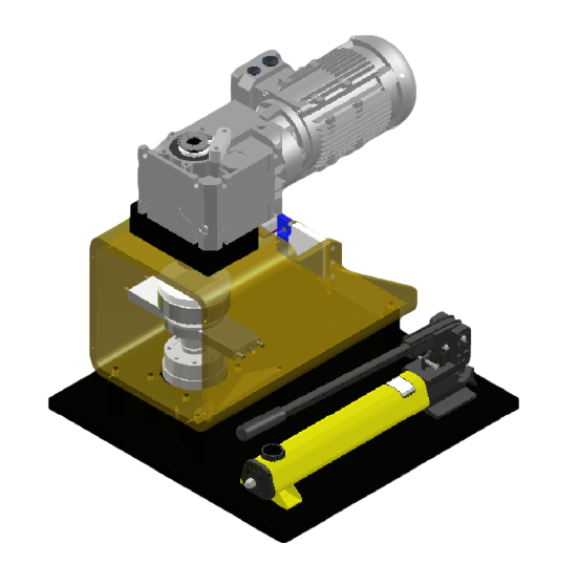

| Loading Method | Hydraulic |

| Load Measurement | Load cell |

| Load Control | Manual |

| Friction Measurement | Force transducer |

| Test Temperature | Ambient |

| Lubrication | Manual |

| Rotational Speed | 0 – 37.4 rpm |

| Motor Type | Three-phase AC gear motor |

| Motor Power | 2.6 kW |

| Maximum Output Torque | 630 Nm |

| Control and Data Acquisition | Touch-screen PLC |

| Data Export | USB storage |

Features

(1) Test geometry and loading configuration fully comply with ASTM G223 requirements.

(2) High-rigidity machine frame minimizes structural deflection under high axial loads.

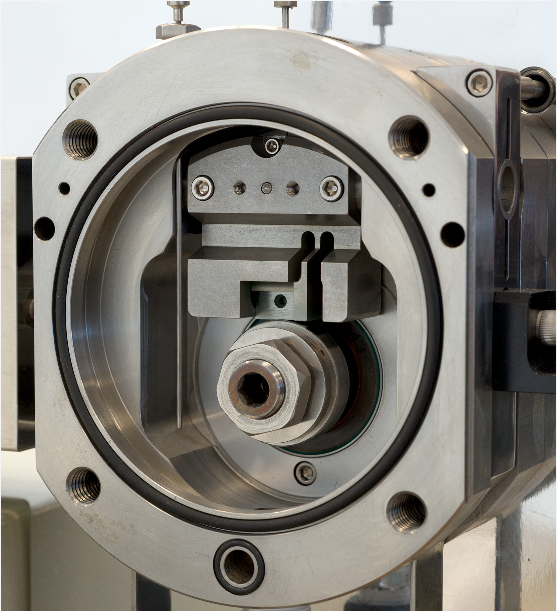

(3) Self-aligning specimen mounting ensures concentric and horizontal contact surfaces.

(4) High-torque, low-speed drive system supports stable testing at high contact pressures.

(5) Direct friction torque measurement using a reaction arm and force transducer.

(6) Manual hydraulic loading allows precise and stable axial force application.

(7) Touch-screen PLC control provides intuitive operation and reliable data acquisition.

(8) USB data export enables efficient post-test analysis and documentation.

Accessories

(1) Hydraulic pump and cylinder assembly

(2) Hollow cylinder specimen fixture compliant with ASTM G223

(3) Flat specimen fixture with adjustable thickness support

(4) Friction torque reaction arm assembly

(5) Load cell for axial force measurement

(6) Lubricants selected according to test requirements

Test Procedures

During testing, you clamp a hollow cylindrical specimen against a flat specimen under an axial compressive load applied by the hydraulic system. The upper specimen is rotated at a controlled low speed by the gear motor, while the lower specimen is torque-reaction mounted.

Friction at the contact interface generates a reaction torque, which is transferred through a lever arm to a force transducer. You use this signal to calculate friction torque and friction coefficient. By analyzing surface damage and material transfer after testing, you evaluate adhesive wear behavior under combined compression and torsion.

Maintenance Information

(1) Regularly inspect the hydraulic system for leaks and pressure stability.

(2) Keep specimen fixtures clean to ensure proper alignment and contact conditions.

(3) Verify load cell and force transducer calibration at scheduled intervals.

(4) Check reaction arm movement to ensure it is free from obstruction.

(5) Inspect electrical connections and PLC operation periodically.

(6) Do not exceed the rated load or maximum output torque during operation.

FAQ

(1) What is this product?

It is a tribology testing machine used to measure friction and adhesive wear under combined axial compression and torsional motion.

(2) What is this product used for?

You use it to evaluate and compare friction coefficients, friction torque, and adhesive wear performance of materials under dry or lubricated conditions.

(3) What is the working principle of this product?

A hollow cylinder specimen is compressed against a flat specimen while one specimen rotates, and the resulting friction torque is measured through a reaction arm and force transducer.

(4) Why is this product important?

It provides standardized, repeatable data for understanding material behavior under high contact pressure and combined loading conditions.

(5) Which industries is this product suitable for?

It is suitable for mechanical engineering, materials science, automotive components, energy equipment, aerospace research, academic laboratories, and industrial testing facilities.

Leave Message Get Price