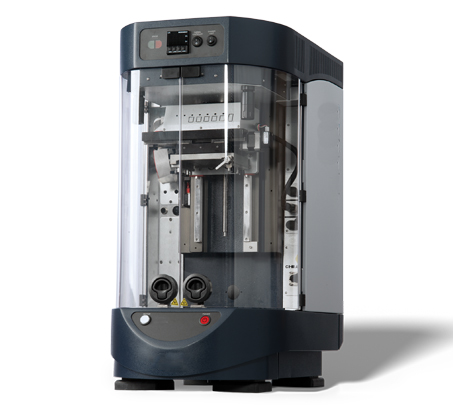

Belt Abrasion Tester

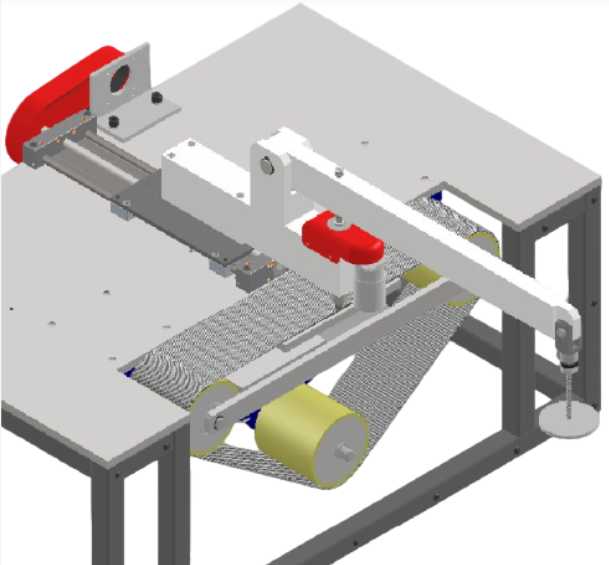

The Belt Abrasion Tester is a laboratory testing instrument designed to evaluate the abrasive wear resistance of materials under controlled three-body abrasion conditions. You use a rotating pin pressed against a continuously moving abrasive belt under a constant dead-weight load, while both the pin rotation and belt speed are precisely controlled. An indexing linear slide ensures that the pin continuously contacts fresh abrasive material, providing repeatable and comparable wear results in accordance with ASTM G132.

Application

You can apply this tester in abrasive wear evaluation for the following materials and test scenarios:

(1) Abrasion resistance testing of metallic materials such as steels, non-ferrous alloys, powder metallurgy parts, and hard alloys.

(2) Wear performance evaluation of engineering ceramics and wear-resistant ceramic components.

(3) Abrasive wear testing of polymers, rubbers, engineering plastics, and composite materials.

(4) Performance comparison of surface-engineered materials including thermal spray coatings, PVD/CVD coatings, and protective wear coatings.

(5) Material screening and formulation comparison during product development.

(6) Quality control and consistency verification for industrial components.

(7) Research studies in tribology laboratories and academic institutions.

(8) Comparative testing between reference pins and test specimens under identical abrasive conditions.

Standards

ASTM G132 – Standard Test Method for Pin Abrasion Testing

Parameters

| Parameter | Specification |

|---|---|

| Pin Diameter | 2 – 10 mm |

| Pin Rotational Speed | 15 – 50 rpm |

| Maximum Load | 200 N (dead-weight loading) |

| Nominal Contact Pressure | 1 – 2.5 MPa |

| Sliding Speed | 10 – 100 m/s |

| Wear Path Length | 4 – 10 m |

| Belt Width | 100 mm |

| Belt Length | 1,200 – 2,000 mm |

| Standard Abrasive | 150-grit garnet |

| Optional Abrasives | 80 – 220 grit |

| Belt Drive | DC geared motor |

| Pin Drive | DC geared motor |

| Indexing Drive | AC servo motor |

| Test Temperature | Ambient |

| Control System | Touch-screen PLC |

Features

(1) Rotating pin-on-rotating belt configuration realistically simulates abrasive cutting and ploughing mechanisms.

(2) Dead-weight loading provides stable and repeatable normal force without control fluctuations.

(3) Indexing linear slide continuously exposes fresh abrasive surfaces, preventing wear track overlap.

(4) Independent control of pin rotation speed and belt sliding speed improves test flexibility.

(5) Low-cogging servo indexing drive ensures accurate and smooth pin positioning.

(6) PLC-based control system reduces operator influence and improves repeatability.

(7) Parallel wear tracks enable direct comparison between test pins and reference pins.

(8) Fully compliant with ASTM G132 requirements for standardized abrasive wear testing.

Accessories

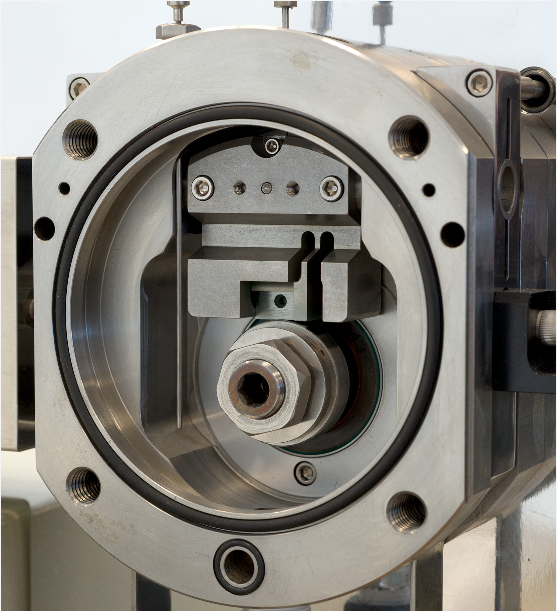

(1) Pin holding fixture for 2–10 mm diameter pins

(2) Indexing linear slide assembly

(3) Abrasive belts, 150-grit garnet

(4) Optional abrasive belts, 80–220 grit

(5) Reference pin for comparative testing

(6) Test pins in different material types

Test Procedures

During testing, you press a rotating pin against a continuously moving abrasive belt under a constant dead-weight load. The belt is driven by a DC motor, while the pin rotates simultaneously to maintain uniform contact conditions.

A motorized indexing slide gradually moves the pin laterally across the belt width, ensuring that each wear pass occurs on unused abrasive material. This maintains consistent wear severity throughout the test and avoids track overlap.

After testing, you evaluate material wear by measuring mass loss, dimensional change, wear rate, and wear track profile.

Maintenance Information

(1) Inspect abrasive belt condition before each test and replace worn belts promptly.

(2) Clean pin holders and belt rollers regularly to prevent debris accumulation.

(3) Verify dead-weight loading components for free movement and correct alignment.

(4) Check indexing slide smoothness and recalibrate if lateral motion becomes uneven.

(5) Periodically inspect motors and electrical connections to ensure stable operation.

FAQ

(1) What is this product?

It is a laboratory abrasive wear testing machine that evaluates material wear resistance using a rotating pin against a moving abrasive belt.

(2) What is this product used for?

You use it to compare abrasive wear performance of metals, ceramics, polymers, and coatings under controlled and standardized conditions.

(3) How does this product work?

A rotating pin is pressed against a moving abrasive belt under constant load, while an indexing mechanism ensures contact with fresh abrasive material throughout the test.

(4) Why is this product important?

It provides repeatable, comparable, and standard-compliant abrasive wear data that supports material selection, product development, and quality control.

(5) Which industries is this product suitable for?

It is suitable for materials research, surface engineering, automotive components, mining and machinery, academic research, and industrial quality laboratories.

Leave Message Get Price