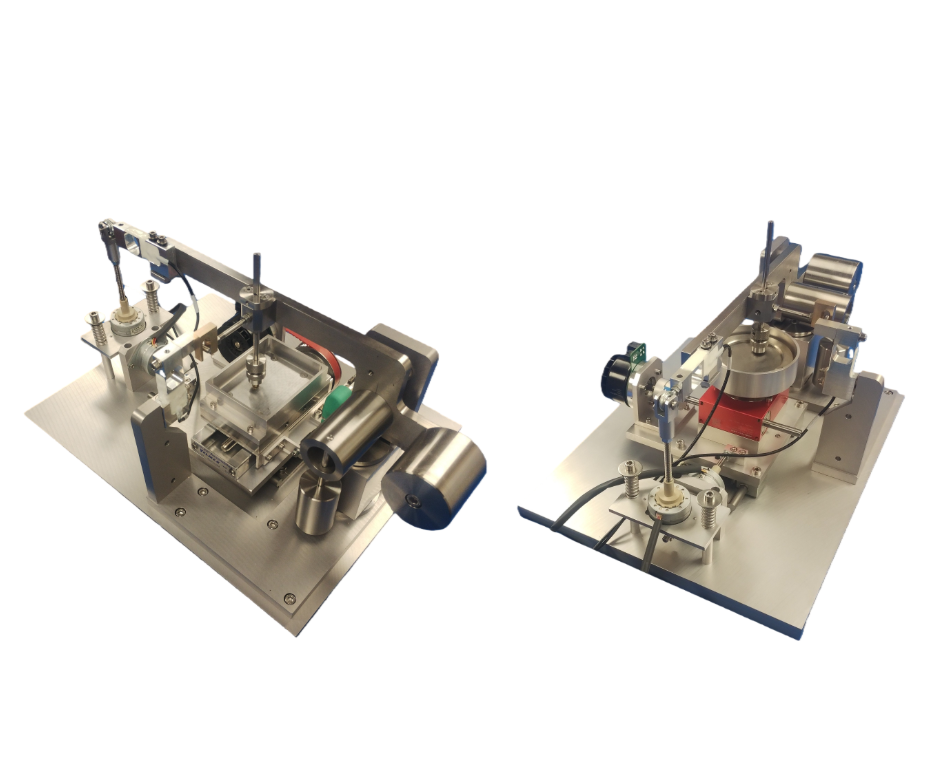

Multi-Axis Tribometer

The Multi-Axis Tribometer is a versatile tribological testing device for studying friction and wear of materials under low to medium load conditions. It supports multiple contact configurations including pin- or ball-on-rotating-disc and pin- or ball-on-plate reciprocating tests. With a lateral indexing function, the device allows continuous exposure of fresh wear surfaces, making it suitable for fundamental tribology research and various standardized test methods.

Application

You can use this tribometer for:

Friction and wear testing of metals, polymers, rubbers, and composite materials.

Pin/ball-on-disc rotational wear tests.

Pin/ball-on-plate reciprocating wear tests.

Studying friction behavior of elastomers and rubber materials.

Evaluating the influence of lubricants on friction, wear, and stick-slip behavior.

Investigating start-up friction and dwell time effects in polymers.

Friction studies on surface coatings and functional thin films.

Simulating friction characteristics of cosmetics or skin-contact materials.

Basic tribology research in teaching and scientific laboratories.

Standards

You can perform tests in accordance with:

ASTM G119 – Guide for Wear Testing.

ASTM G99 – Pin/ball-on-disc friction and wear test.

ASTM G132 – Pin-on-disc wear test with indexing function.

DIN 50324 – Pin-on-disc friction and wear testing.

Parameters

Base Unit

| Parameter | Specification |

|---|---|

| Contact Configuration | Ball-on-flat / Pin-on-flat / Custom samples |

| Normal Load Range | 0.1 – 100 N |

| Load Measurement | Strain gauge force sensor |

| Friction Force Range | 0 – 50 N |

| Friction Measurement | Strain gauge force sensor |

| Humidity Measurement | 10 – 90 % RH |

| Drive Motor | Brushless DC servo, 200 W |

| Loading Actuator | Linear actuator, 12 V DC, 100 N |

| Indexing Actuator | Linear actuator, 12 V DC, 100 N |

| Interface | USB serial interface |

| Control Software | Proprietary control software |

| Installation | Benchtop |

| Protection | Transparent safety shield |

P-Indexed Pin-on-Disc Module

| Parameter | Specification |

|---|---|

| Contact Configuration | Ball-on-disc / Pin-on-disc |

| Disc Diameter | 100 mm |

| Track Radius | 0 – 40 mm |

| Lateral Feed Speed | 10 mm/min |

| Disc Speed | 0 – 300 rpm |

| Maximum Sliding Velocity | 1 m/s |

R-Indexed Reciprocating Module

| Parameter | Specification |

|---|---|

| Contact Configuration | Ball-on-plate / Plate-on-plate / Plate-on-hemisphere |

| Max Reciprocating Velocity | 10 mm/s |

| Max Stroke | 50 mm |

| Max Lateral Velocity | 1 mm/s |

| Max Lateral Travel | 30 mm |

| Temperature Range | Ambient – 100°C |

| Dwell Time | 0 – 8 hours |

| Temperature Sensor | Type J thermocouple |

| Heating Power | 150 W |

H High-Temperature Non-Indexed Pin-on-Disc Module

| Parameter | Specification |

|---|---|

| Disc Diameter | 75 mm |

| Track Radius | 0 – 35 mm |

| Temperature Range | Ambient – 500°C |

R/C Cooling Module

| Parameter | Specification |

|---|---|

| Minimum Temperature | −15°C (ambient water cooling) |

| Minimum Temperature | −30°C (chiller water/ethylene glycol) |

Features

(1) Multi-axis, multi-module configuration covers both rotational and reciprocating tests.

(2) Indexing function allows continuous exposure of fresh wear surfaces, meeting ASTM G132 requirements.

(3) Electric loading system supports pre-test dwell time settings.

(4) Force-decoupled structure measures only tangential friction force, avoiding normal load interference.

(5) Stable friction measurements for elastomers and large-deformation samples.

(6) Modular design allows quick change of test configurations.

(7) Supports temperature and humidity monitoring and controlled environmental tests.

(8) Automatic data recording with export in .csv or .tsv format.

Accessories

(1) /P Indexed Pin-on-Disc Module

(2) /R Indexed Reciprocating Module

(3) /H High-Temperature Pin-on-Disc Module

(4) /R/S Stick-Slip Test Adapter

(5) /R/R Rubber Friction Test Fixture

(6) /R/C Cooling Module

(7) Test samples – Pin / Ball (user-supplied)

(8) Test samples – Disc / Plate (user-supplied)

Test Procedures

Principle:

The tribometer applies precise normal loads using electric linear actuators. Pins or balls are mounted on gimbal-supported beams and contact rotating discs or reciprocating plates. Friction is independently measured by strain sensors to avoid interference from normal loads. Lateral indexing shifts the contact area during the test, exposing fresh surfaces for multi-track or spiral wear paths, yielding reproducible and stable wear data.

Operation:

(1) Select the module according to the test type and install properly.

(2) Mount samples ensuring proper alignment and fixation.

(3) Set normal load and verify sensor zero.

(4) For elastomer tests, set appropriate dwell time.

(5) Confirm temperature control system stability for high- or low-temperature tests.

(6) Verify lateral travel and speed for indexing tests.

(7) Do not open protective shield during testing.

Experimental Workflow:

ASTM G99 Pin-on-Disc Test

(1) Mount pin/ball and disc samples.

(2) Set track radius and disc speed.

(3) Apply load and configure test duration.

(4) Start the test and record friction data.

(5) Analyze wear after test completion.

ASTM G132 Indexed Wear Test

(1) Set indexing step and feed speed.

(2) Perform multi-track continuous wear loading.

(3) Ensure pins contact fresh surfaces throughout the test.

(4) Record friction coefficient variation across the tracks.

Maintenance Information

(1) Inspect linear actuators and force sensors regularly.

(2) Clean modules and samples to prevent contamination.

(3) Verify temperature control, heating, and cooling modules before high/low temperature tests.

(4) Check indexing mechanism for smooth operation.

(5) Store modular accessories properly to avoid damage.

FAQ

(1) What is this product?

It is a multi-axis tribometer for studying friction and wear under low to medium load conditions.

(2) What is this product used for?

You can perform rotational and reciprocating wear tests on metals, polymers, rubbers, and coatings with precise control and indexing.

(3) How does this product work?

Pins or balls contact discs or plates under controlled load, friction is measured by strain sensors, and indexing exposes fresh wear surfaces for reproducible results.

(4) Why is this product important?

It enables accurate, repeatable tribological testing across multiple materials and environmental conditions.

Leave Message Get Price