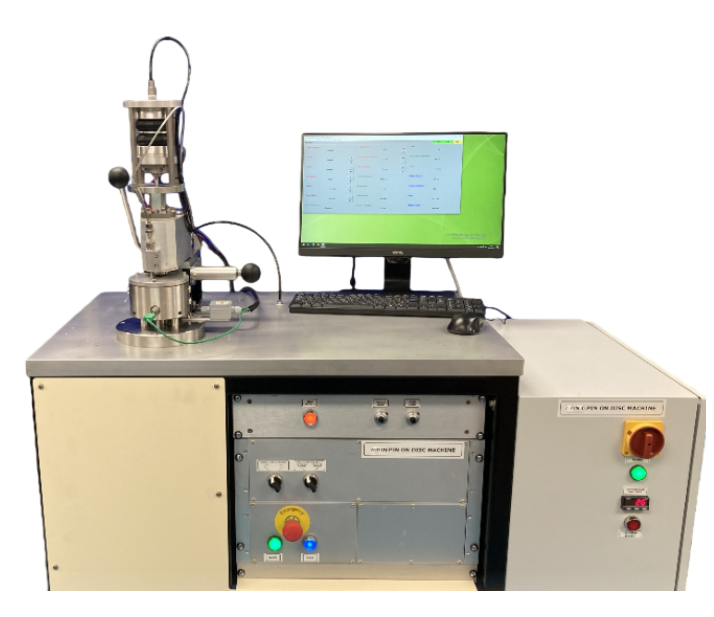

Pin-on-Disc Machine

The Pin-on-Disc Machine is a classic tribological testing instrument designed for studying friction, wear, and contact behavior of materials under controlled sliding conditions. You can use a pin or ball sample loaded vertically against a rotating horizontal disc to simulate real-world sliding contacts. The instrument features a pneumatic loading system that minimizes inertia effects on friction and wear response, making it suitable for dry, lubricated, and extended contact-type testing.

Application

You can apply this machine for:

(1) Evaluating dry friction and wear performance of metals, ceramics, and composite materials.

(2) Studying friction coefficient and wear behavior under lubricated conditions.

(3) Assessing wear resistance of coatings and surface-treated layers.

(4) Comparing tribological performance of lubricants.

(5) Friction and wear research of bearing and engineering materials.

(6) Simulating line or surface contact for piston ring–cylinder liner materials.

(7) Testing sliding bearing and journal materials.

(8) Investigating material wear under reciprocating motion.

(9) Correlating friction state with contact potential.

Standards

You can perform tests according to these procedures:

(1) ASTM G99 – Pin-on-Disc wear testing method.

(2) ASTM F732 – Reciprocating pin-on-plate friction test method.

(3) DIN 50324 – Methods for testing friction and wear.

(4) ISO/DIS 7148-2 – Guidelines for pin-on-disc friction and wear testing.

Parameters

| Parameter | Specification |

|---|---|

| Rotational Speed | 20 – 2,000 rpm |

| Equivalent Sliding Velocity | 0.05 – 8 m/s |

| Test Track Radius | 0 – 35 mm |

| Load Method | Pneumatic / Weight loading |

| Pneumatic Load Range | 25 – 1,000 N |

| Weight Load Range | 5 – 100 N |

| Cyclic Load Amplitude | Up to 50% of set load |

| Cyclic Load Form | Sine / Triangle |

| Cyclic Load Frequency | Max 1 Hz |

| Friction Force Measurement | 0 – 50 N / 0 – 1,000 N |

| Wear Measurement | LVDT displacement sensor |

| Wear Measurement Range | 0 – 2.5 mm |

| Wear Resolution | <1 µm |

| Contact Potential | 40 mV DC |

| Temperature Measurement | K-type thermocouple |

| Disc Sample | Ø75 mm × 8 mm |

| Pin Sample | Ø8 mm × 35–68 mm |

| Ball Sample | Ø6 mm |

| Drive Motor | 2.2 kW AC vector motor |

| Control & Data Acquisition | Software + USB interface |

Features

(1) Pneumatic loading reduces inertia influence on friction and wear results.

(2) Rigid pin and disc support structure simulates near-flat contact conditions.

(3) Vector-controlled AC motor ensures stable rotation and wide speed range.

(4) Low rotational inertia pin holder enables high-bandwidth friction signal measurement.

(5) Supports constant and periodic cyclic load tests.

(6) Contact potential measurement allows friction state analysis.

(7) Modular design allows multiple sliding and contact configurations.

(8) Supports both rotary and reciprocating motion modes.

Accessories

(1) Standard Ø8 mm pin sample holder.

(2) Standard Ø6 mm ball sample fixture.

(3) Pneumatic loading assembly with load sensor.

(4) Contact potential measurement assembly with slip ring.

(5) Optional LE lubrication test chamber ≤200°C.

(6) Optional HT hot air heating system ≤400°C for dry friction.

(7) Optional R reciprocating adapter, stroke 0–50 mm.

(8) Optional LCA line contact adapter for piston ring–cylinder liner tests.

(9) Optional PV Pin-V / Block-Ring adapter for high-load tests.

(10) CAL calibration kit for load and friction.

Test Procedures

Pin-on-Disc Wear Test (ASTM G99)

(1) Install pin or ball sample and disc.

(2) Set load, rotational speed, track radius, and test duration.

(3) Start test and monitor friction force and wear.

(4) Test completes automatically after reaching set sliding distance.

(5) Analyze wear scar and calculate friction coefficient.

Reciprocating Pin Test (ASTM F732)

(1) Install reciprocating adapter and plate sample.

(2) Set stroke, frequency, load, and temperature.

(3) Run test while recording friction and wear.

(4) Evaluate wear resistance of material after completion.

Maintenance Information

(1) Ensure power supply and pneumatic connections are clean and dry.

(2) Clean samples and test surfaces after each test to prevent contamination.

(3) Inspect pneumatic and weight-loading systems for accuracy.

(4) Calibrate friction sensors and LVDT periodically.

(5) Check disc and pin holder alignment to avoid eccentric loading.

(6) Store consumables properly to maintain integrity.

FAQ

(1) What is this product?

It is a pin-on-disc tribometer for friction and wear testing under controlled sliding contacts.

(2) What is this product used for?

You can evaluate friction, wear, lubricant performance, and material contact behavior.

(3) How does this product work?

A pin or ball sample is loaded against a rotating disc. Friction is measured by a sensor, and wear is monitored via an LVDT sensor. Pneumatic or weight loading can apply constant or cyclic forces.

(4) Why is this product important?

It provides precise, repeatable measurement of friction and wear, supporting material development, lubrication studies, and quality control.

(5) Which industries is this product suitable for?

Automotive, aerospace, industrial machinery, lubricant R&D laboratories, coatings, and materials research.

Leave Message Get Price