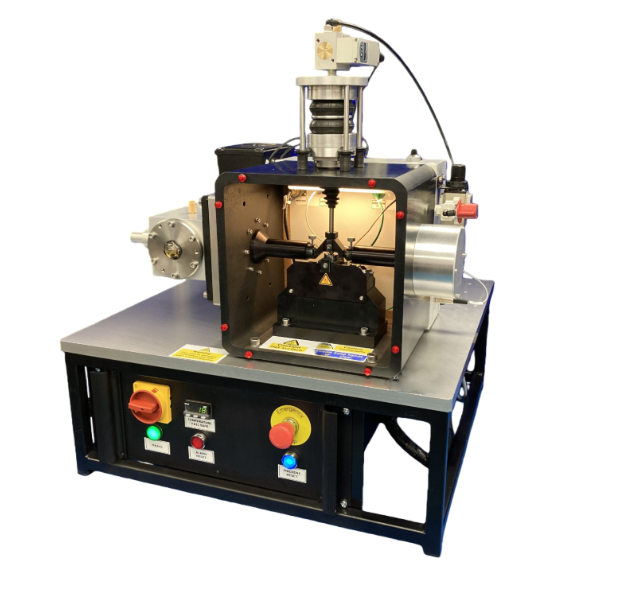

Reciprocating Tribometer

The Reciprocating Tribometer is a value-engineered tribological testing instrument designed for lubricated ball-on-flat experiments. You can perform high-frequency linear oscillation tests to evaluate friction, wear, and extreme pressure (EP) properties of lubricating greases, oils, and solid bonded films. The instrument combines a servo-pneumatic loading system, Scotch Yoke reciprocating mechanism, and touch-screen PC control for precise management of load, stroke, frequency, and temperature. You can collect real-time friction data via a piezoelectric transducer and export all test results for analysis.

Application

You can apply this tribometer for:

Evaluating lubricating grease friction and wear performance under high Hertzian contact.

Measuring extreme pressure (EP) properties of lubricating oils and solid bonded films.

Assessing fretting wear resistance of greases and lubricated components.

Determining scuffing limits and friction coefficients of mechanical transmission fluids.

Lubricated ball-on-flat and cylinder-on-flat contact tests for research and industrial labs.

Friction and wear testing of automotive transmission, hydraulic, and industrial lubricants.

Material screening and quality control in R&D or laboratory settings.

Standards

ASTM D5706 – EP properties of lubricating greases using high-frequency linear oscillation.

ASTM D5707 – Friction and wear of lubricating greases using high-frequency linear oscillation.

ASTM D6425 – Friction and wear of extreme pressure (EP) lubricating oils using high-frequency linear oscillation.

ASTM D7217 – EP properties of solid bonded films using high-frequency linear oscillation.

ASTM D7421 – EP properties of lubricating oils using high-frequency linear oscillation.

ASTM D7594 – Fretting wear resistance of lubricating greases under high Hertzian pressures.

ASTM D8227 – Coefficient of friction of synchronizers lubricated by mechanical transmission fluids (MTF).

ASTM D8503 – Scuffing temperature limit of lubricating oils using high-frequency linear oscillation.

Parameters

| Parameter | Specification |

|---|---|

| Load Type | Servo-controlled pneumatic bellows |

| Load Measurement | Strain gauge force transducer |

| Friction Force Measurement | Piezo transducer |

| Load Range | 25–1,200 N |

| Amplitude (Stroke) | 0.15 (0.30) mm, 0.5 (1.0) mm, 1.0 (2.0) mm, 1.5 (3 mm), 2.0 (4 mm) |

| Maximum Frequency | 50 Hz |

| Temperature Range | Ambient to 250°C |

| Temperature Sensor | K-type thermocouple |

| Test Samples | 10 mm diameter ball, 10 mm diameter cylinder |

| Control & Data Acquisition | Touch-screen PC & interface |

| Data Export | USB stick |

| Automatically Controlled | Frequency, Load, Temperature, Test Duration |

| Manually Controlled | Amplitude (Stroke) |

| Measured Parameters | Frequency, Load, Friction, Temperature, Test Duration, Friction Coefficient |

Features

(1) Touch-screen PC control for automatic sequence management and real-time data logging.

(2) Servo-pneumatic load system with strain gauge feedback ensures precise, repeatable loads.

(3) Scotch Yoke mechanism provides stable sinusoidal reciprocating motion.

(4) Fixed stroke lengths selectable via interchangeable cams for consistent test conditions.

(5) Piezoelectric transducer enables high-accuracy friction force measurement.

(6) Compatible with ball-on-flat and cylinder-on-flat test samples.

(7) Supports high-frequency testing up to 50 Hz for accelerated wear studies.

(8) Data export via USB allows easy post-test analysis and reporting.

Accessories

Interchangeable cams for setting fixed stroke lengths.

Test balls – 10 mm diameter, steel or ceramic.

Test cylinders – 10 mm diameter, steel or ceramic.

Optional cooling module for extended temperature control.

Optional in-situ profilometer for wear tracking.

Consumables for greases, oils, and solid film samples.

Test Procedures

(1) Connect electricity and dry, clean air (4 cfm at 8 bar / 120 psi).

(2) Install the appropriate ball or cylinder sample.

(3) Set stroke amplitude manually via cam selection.

(4) Configure load, frequency, temperature, and test duration through touch-screen PC.

(5) Start the test, monitor friction, load, and temperature in real-time.

(6) After completion, export data to USB and evaluate friction coefficient, wear, and other test results.

(7) For high-temperature tests, ensure thermocouples and heating elements are operational.

(8) Regularly inspect samples and transducers for accuracy and repeatability.

Maintenance Information

(1) Ensure power and air supply meet specifications before operation.

(2) Clean test samples and holders after each test to prevent contamination.

(3) Verify the function of the load control system and sensors periodically.

(4) Calibrate piezo transducers and thermocouples according to schedule.

(5) Inspect mechanical components of Scotch Yoke and cams for wear.

(6) Store consumables in a dry environment to maintain integrity.

FAQ

(1) What is this product?

It is a high-frequency reciprocating tribometer for lubricated ball-on-flat friction and wear testing.

(2) What is this product used for?

You can evaluate friction, wear, extreme pressure, fretting, and scuffing characteristics of lubricants and lubricated components.

(3) How does this product work?

The device uses a servo-motor-driven Scotch Yoke mechanism to generate sinusoidal reciprocating motion. Load is applied via a servo-pneumatic bellows, friction is measured by a piezoelectric transducer, and temperature is monitored with a K-type thermocouple.

(4) Why is this product important?

It allows you to precisely quantify friction, wear, and EP performance under controlled high-frequency conditions, aiding lubricant development and component performance assessment.

(5) Which industries is this product suitable for?

Automotive, aerospace, industrial machinery, lubricant R&D laboratories, and material research centers.

Leave Message Get Price