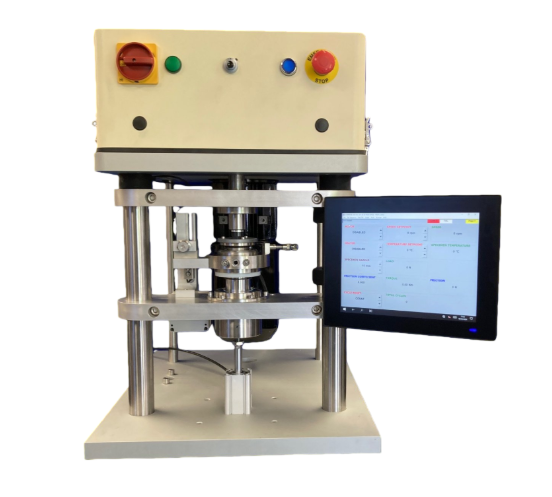

Dry Friction and Wear Tribometer (Value Engineered Tribometer)

The Dry Friction and Wear Tribometer is a value-engineered, multi-functional testing instrument designed to study the friction and wear behavior of materials under dry or self-lubricated conditions. You can precisely control load, speed, and temperature through pneumatic loading, while an air-bearing friction assembly and touch-screen PC interface provide accurate measurement and data logging. The instrument supports online or offline wear measurement and is suitable for both research and industrial laboratory evaluation of material tribological performance.

Application

You can use this tribometer for:

(1) Evaluating dry friction and wear performance of metals, alloys, ceramics, and composite materials.

(2) Measuring wear rate of self-lubricating materials under sliding conditions.

(3) Assessing friction and wear performance of surface-engineered materials, including coatings, films, and heat-treated layers.

(4) Studying friction coefficients and wear behavior of engineering plastics and polymer materials.

(5) Pin-on-disc friction and wear testing.

(6) Thrust washer self-lubricating wear testing.

(7) Screening material tribological properties during development.

(8) Industrial product quality control and failure analysis.

Standards

You can perform tests in accordance with the following international standards:

(1) ASTM D3702 – Standard Test Method for Wear Rate of Materials in Self-Lubricated Rubbing Contact Using a Thrust Washer Testing Machine

(2) ASTM G99 – Standard Test Method for Wear Testing with a Pin-on-Disc Apparatus

Note: The instrument structure and control logic are consistent with internationally recognized pin-on-disc and thrust washer test devices, ensuring compliance with relevant research and benchmark testing requirements.

Parameters

| Parameter | Specification |

|---|---|

| Thrust Washer Test | Compliant with ASTM D3702 |

| Pin-on-Disc Test | Compliant with ASTM G99 |

| Pin Track Radius | 10–35 mm |

| Pin Dimensions | Ø8 mm × 15 mm |

| Test Disc Diameter | Maximum 75 mm |

| Load Range | 20–750 N (@6 bar air pressure) |

| Load Application | Pneumatic |

| Load Measurement | Pressure sensor |

| Load Control | Manual precision regulator |

| Friction Measurement | Databeam strain gauge sensor |

| Torque Reaction Support | Air bearing |

| Temperature Range | Ambient to 200°C |

| Heating Power | 550 W |

| Temperature Sensor | K-type thermocouple |

| Speed Range | 30–1,800 rpm |

| Motor | 1.5 kW AC vector motor |

| Control & Data Acquisition | Touch-screen PC interface |

| Data Export | USB |

Features

(1) Touch-screen PC interface allows automatic control of speed, temperature, test duration, and data logging.

(2) Pneumatic loading system with precision regulator provides stable and repeatable load application.

(3) Air-bearing mounted friction and load assembly minimizes system friction interference for higher measurement accuracy.

(4) Supports both pin-on-disc and thrust washer testing modes.

(5) Optional capacitance probe enables real-time, online wear measurement.

(6) Real-time calculation and output of friction coefficient, friction force, and sliding speed.

(7) Compact structure suitable for laboratory and industrial material testing environments.

Accessories

(1) Standard Pin-on-Disc Test Assembly – compliant with ASTM G99

(2) Standard Thrust Washer Test Assembly – compliant with ASTM D3702

(3) Optional Capacitance Wear Sensor – online wear measurement

(4) Consumables: Test Pins Ø8 mm × 15 mm

(5) Consumables: Test Discs, maximum diameter 75 mm

(6) Consumables: Thrust Washer Samples – per ASTM D3702

Test Procedures

Pin-on-Disc Wear Test (ASTM G99)

Install the test disc and secure the test pin.

Set pin track radius, speed, load, and test duration.

Start the test and monitor friction force, friction coefficient, and temperature in real time.

After completion, measure wear volume or analyze online wear data.

Thrust Washer Wear Test (ASTM D3702)

Install the thrust washer assembly.

Set the specified load, speed, and test duration.

Start the test and monitor friction parameters.

Calculate material wear resistance based on wear volume or wear rate.

Maintenance Information

(1) Ensure proper power supply and dry, clean air source connections.

(2) Regularly inspect and clean test pins, discs, and thrust washers.

(3) Check pneumatic system and sensors for accuracy before each test.

(4) Calibrate load, friction, and temperature sensors periodically.

(5) Allow high-temperature parts to cool before handling.

FAQ

(1) What is this product?

It is a tribometer designed to evaluate friction and wear behavior of materials under dry or self-lubricating conditions.

(2) What is this product used for?

You can measure friction coefficients, wear rate, and material performance for research, development, and industrial quality control.

(3) How does this product work?

The instrument applies load pneumatically to a pin or thrust washer in contact with a rotating disc. Friction and torque are measured with strain gauges, while air-bearing support reduces interference. Optional sensors allow real-time wear monitoring.

(4) Why is this product important?

It provides accurate and reproducible data on material tribological properties, essential for product development, reliability assessment, and quality control.

(5) Which industries is this product suitable for?

Automotive, aerospace, industrial machinery, material research labs, and quality control laboratories.

Leave Message Get Price