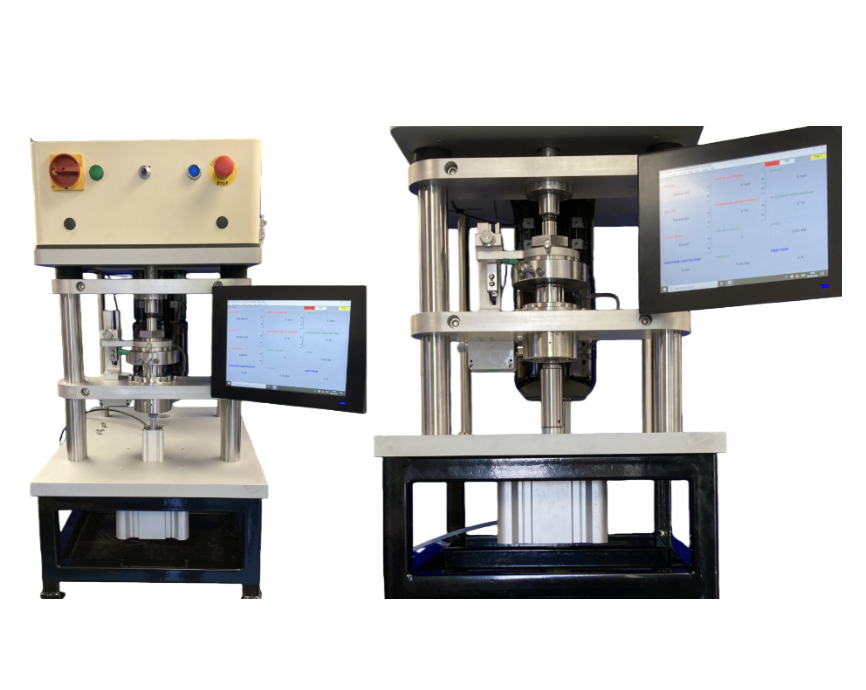

Four-Ball Tribometer(Value Engineered Tribometer)

The Four-Ball Tribometer is a high-precision laboratory instrument designed to evaluate the wear resistance, extreme-pressure (EP) performance, and friction characteristics of lubricating greases and oils. You can control load, speed, and temperature with high accuracy through pneumatic low/high load cylinders and an air-bearing torque measurement system. The instrument features a touch-screen PC interface for data acquisition and supports optional modules for rolling four-ball tests, shear stability evaluation, and high-resolution wear scar measurement.

Application

You can use this tribometer for a wide range of laboratory tests, including:

(1) Evaluating wear resistance of lubricating greases and oils.

(2) Assessing extreme-pressure (EP) performance of lubricants.

(3) Measuring friction coefficients for research and quality control.

(4) Performing rolling contact fatigue tests with the optional rolling four-ball module.

(5) Conducting shear stability tests on polymer-containing lubricants (optional KRL module).

(6) Measuring and analyzing wear scars using an optional high-resolution digital microscope.

(7) Laboratory testing of automotive, industrial, and hydraulic lubricants.

(8) Quality control of lubricants in research and production labs.

Standards

(1) ASTM D2266 – Wear performance of lubricating grease

(2) ASTM D4172 – Wear performance of lubricating oil

(3) ASTM D2596 – Extreme-pressure performance of lubricating grease

(4) ASTM D2783 – Extreme-pressure performance of lubricating oil

(5) ASTM D5183 – Friction coefficient of lubricants (four-ball method)

(6) IP 239 – Lubricant extreme-pressure and wear tests

(7) DIN 51350/1-5 – Four-ball testing of lubricants

(8) ISO/CD 11008 – Extreme-pressure performance of lubricating grease (four-ball method)

(9) IP 300 – Rolling contact fatigue test (optional)

(10) DIN 51350/6 – Shear stability of polymer-containing lubricants (optional)

(11) CEC L-45-A-99 – Transmission oil shear stability test (optional)

(12) ISO 26422:2014 – Shear stability of polymer-containing lubricants (optional)

Parameters

| Parameter | Specification |

|---|---|

| Test Ball Diameter | 12.7 mm (0.5″) |

| Total Load Range | 10–8,000 N |

| Low Load Range | 20–750 N (@6 bar air) |

| High Load Range | 50–8,000 N (@4 bar air) |

| Load Application | Pneumatic |

| Load Measurement | Pressure sensor |

| Load Control | Manual precision regulator |

| Friction Measurement | Strain gauge sensor |

| Torque Reaction Support | Air bearing |

| Speed Range | 60–1,800 rpm |

| Temperature Range | Ambient to 200°C |

| Temperature Sensor | K-type thermocouple |

| Motor | 1.5 kW AC vector motor |

| Control & Data Acquisition | Touch-screen PC interface |

| Data Export | USB |

| Digital Microscope Resolution | 2 mm range 0.01 mm; 4 mm range 0.02 mm |

Features

(1) Touch-screen PC interface enables automated control of speed, temperature, and test duration.

(2) Pneumatic low/high load cylinders provide accurate and repeatable load application.

(3) Air-bearing friction and torque measurement system ensures precise data.

(4) Built-in standard test programs for ASTM, DIN, IP, and ISO/CD methods.

(5) Optional digital microscope allows high-resolution wear scar measurement without sample disassembly.

(6) Expandable modules support rolling four-ball and KRL shear stability tests.

(7) Compact and robust design suitable for laboratory environments.

(8) Manual load adjustment enables precise low-load testing.

Accessories

(1) DM – Digital microscope with camera and PC software for wear scar analysis

(2) R4B – Rolling four-ball test module (optional)

(3) KRL – Shear stability test adapter (optional)

(4) SM – Temperature control module for KRL tests (optional)

Test Procedures

Four-Ball Wear Test (ASTM D2266 / D4172)

Install three stationary balls and one rotating ball in the fixture.

Fill the test cup with the specified lubricant.

Set test parameters: load (e.g., 40 kgf), speed (e.g., 1,200 rpm), temperature, and duration (e.g., 60 min).

Ensure the safety cover is in place, then start the test via the touch-screen PC.

Monitor torque, temperature, and load in real time.

After completion, measure wear scar diameter using the digital microscope or manual method.

Record friction coefficient and wear data.

Extreme-Pressure Test (ASTM D2596 / D2783)

Apply load progressively using pneumatic cylinders.

Observe and record the lubricant’s EP limit or weld point.

Data is automatically logged via the PC interface.

Maintenance Information

(1) Confirm air supply and power connections are stable and clean.

(2) Regularly inspect and clean the test fixture, balls, and lubricant cup.

(3) Drain and clean the lubrication system after each test to prevent contamination.

(4) Calibrate load, torque, and temperature sensors periodically to maintain accuracy.

(5) Ensure moving parts are free of debris and properly lubricated where applicable.

FAQ

(1) What is this product?

It is a high-precision tribometer designed to measure wear, extreme-pressure performance, and friction of lubricants using the four-ball method.

(2) What is this product used for?

You can evaluate the wear resistance, extreme-pressure capability, friction coefficient, and shear stability of greases and oils for research, development, and quality control purposes.

(3) How does this product work?

Three stationary balls are loaded in a fixture while a fourth ball rotates under controlled load. Friction, torque, and temperature are measured with sensors, and optional modules simulate rolling contact fatigue or shear stress.

(4) Why is this product important?

It provides reproducible, traceable, and standardized testing of lubricant performance, which is critical for product development, reliability, and quality assurance.

(5) Which industries is this product suitable for?

Automotive, industrial machinery, hydraulic systems, lubricant R&D labs, and quality control laboratories.

Leave Message Get Price