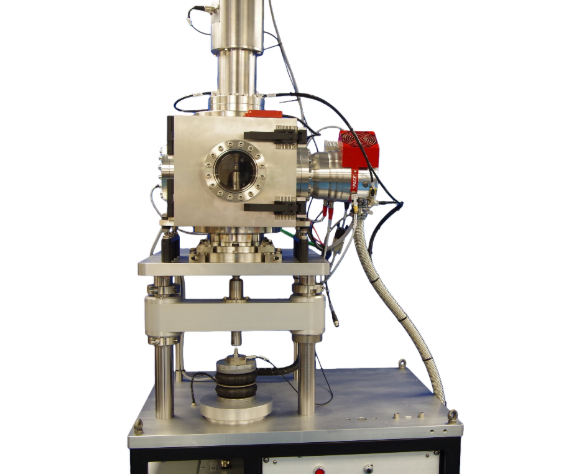

Precision Rotary Vacuum Tribometer

Precision Rotary Vacuum Tribometer is a laboratory-grade tribological testing system designed for friction, wear, and rolling contact fatigue testing under controlled vacuum, inert gas, or atmospheric environments. You use this instrument to simulate real contact conditions between materials by precisely controlling load, rotational speed, pressure, and test duration. The system integrates a sealed vacuum test chamber, servo-driven rotary spindle, pneumatic load actuation, and high-resolution torque and force measurement to support advanced tribology research and materials evaluation.

Application

You can use the Precision Rotary Vacuum Tribometer for the following applications and test configurations:

Sliding friction and wear testing of metals, coatings, ceramics, and lubricated materials

Tribological performance evaluation under vacuum or controlled gas environments

Boundary lubrication and dry contact behavior analysis

Rolling contact fatigue testing of bearing materials and surface treatments

Comparative material screening for aerospace, vacuum, and high-reliability applications

Typical supported test configurations include:

Four-ball wear test (ASTM D2266)

Thrust washer test (ASTM D3702)

Three-pin-on-disc / pin-on-disc test (ASTM G99)

Spiral orbit ball-on-disc rolling contact fatigue test (ASTM F2661)

Standards

The system supports test configurations equivalent to the following standards:

(1) ASTM D2266 – Standard Test Method for Wear Preventive Characteristics of Lubricating Grease (Four-Ball Method)

(2) ASTM D3702 – Standard Test Method for Wear Rate and Friction Coefficient of Materials in Self-Lubricated Rubbing Contact

(3) ASTM G99 – Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus

(4) ASTM F2661 – Standard Test Method for Rolling Contact Fatigue Using a Ball-on-Disk Configuration

(5) ISO 7148 – Plain bearings — Testing of tribological properties of bearing materials

Parameters

Tribometer System

| Parameter | Specification |

|---|---|

| Load Range | 20 – 2000 N |

| Rotational Speed | 10 – 1700 rpm |

| Maximum Friction Torque | 5 Nm |

| Load Actuation | Pneumatic bellows |

| Motor Type | Servo motor with encoder feedback |

| Speed Control Ratio | 100:1 |

| Test Configurations | Four-ball, thrust washer, pin-on-disc, spiral orbit ball-on-disc |

| Roughing Pump | Rotary vane pump |

| High Vacuum Pump | Turbomolecular pump |

Test Chamber

| Parameter | Specification |

|---|---|

| Ultimate Vacuum | Down to 100 picobar (10⁻⁵ Pa) |

| Environment | Air, inert gas, or vacuum |

| Chamber Material | 304 stainless steel |

| Surface Finish | Glass bead blasted |

| Viewports | Fused silica |

| Electrical Feedthrough | 1 kV, 15 A |

| Coaxial Feedthrough | BNC flange |

| Thermocouple | Type K |

| Vacuum Measurement | Cold cathode and Pirani gauges |

| Leak Rate | < 10⁻⁷ mbar·L/s |

| Rotary Feedthrough Pressure | Up to 10⁻⁷ Pa |

| Rotary Feedthrough Temperature | Up to 80 °C |

Features

Bench-mounted vacuum tribometer with fully sealed stainless-steel test chamber

Servo-driven rotary spindle with high speed stability and encoder feedback

Pneumatic bellows load system with in-line force transducer for precise load control

High-resolution friction torque measurement using torsional flexure and capacitance sensing

Electrical insulation and slip-ring design for electrical contact potential measurement

Bake-out heaters to support chamber out-gassing and vacuum preparation

Supports both sliding wear and rolling contact fatigue testing

Accessories

(1) Four-ball wear test adapter

(2) Thrust washer test adapter

(3) Pin-on-disc / three-pin-on-disc adapter

(4) Spiral orbit ball-on-disc rolling contact fatigue adapter

(5) Electrical slip ring assembly

(6) Bake-out heater assembly

(7) Vacuum pumping system and gauges

Test Procedures

(1) Mount the rotating and fixed specimens using the appropriate test adapter.

(2) Seal the test chamber and connect vacuum, gas, and electrical feedthroughs.

(3) Set test parameters including load, rotational speed, and test duration.

(4) Adjust operating pressure manually and verify chamber stability.

(5) Start the test sequence and record friction, load, torque, temperature, and pressure data.

(6) Stop the test after completion and safely vent the chamber before specimen removal.

Maintenance Information

You should regularly inspect seals, bellows, and rotary feedthroughs to ensure vacuum integrity. Load transducers, torque sensors, and capacitance probes should be calibrated periodically. The test chamber must be cleaned after abrasive or lubricated tests, and vacuum pumps should be maintained according to manufacturer service schedules to ensure stable long-term operation.

FAQ

(1) What is this product?

This product is a precision laboratory tribometer designed to measure friction, wear, and rolling contact fatigue under vacuum, inert gas, or atmospheric conditions using controlled mechanical loading and rotation.

(2) What is this product used for?

You use it to evaluate tribological performance of materials, coatings, and lubricated contacts, especially for applications where vacuum or controlled environments are required.

(3) How does this product work?

The system applies a controlled normal load via a pneumatic bellows while a servo-driven spindle rotates the specimen. Sensors measure friction torque, force, displacement, temperature, and electrical contact potential during the test.

(4) Why is this product important?

It allows you to reproduce realistic contact conditions with high repeatability, enabling accurate assessment of material behavior, wear mechanisms, and fatigue performance without relying on full-scale systems.

(5) Which industries is this product suitable for?

It is suitable for aerospace, materials science, surface engineering, vacuum technology, lubrication research, academic research institutions, and industrial R&D laboratories.

Leave Message Get Price