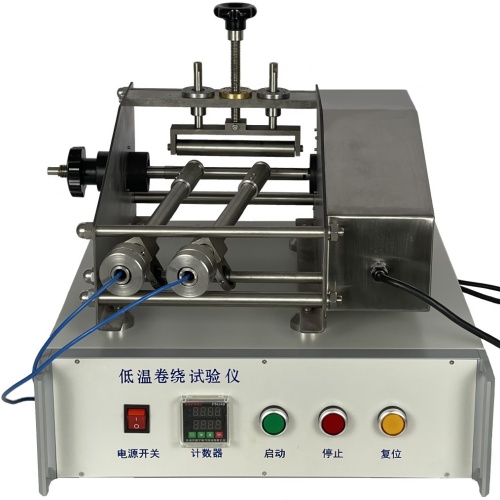

Automotive Wire Low-Temperature Winding Tester

The Automotive Wire Low-Temperature Winding Tester is designed for low-temperature tensile, winding, and impact tests of wires, cables, and electrical accessories. It evaluates the mechanical and electrical performance of products under low-temperature conditions and simulates storage, transportation, and usage in extreme environments.

Application

The tester is suitable for:

Automotive wires and cables

Electrical accessories and components

Testing low-temperature bending, winding, and impact resistance

Evaluating electrical and mechanical performance under low-temperature conditions

Assessing durability and corrosion resistance of samples in extreme environments

Applicable in electrical, electronics, instrumentation, and automotive component industries

Standards

The tester complies with the following standards:

(1) GB/T 2951.14-2008 – Low-temperature bending test for wires and cables (China)

(2) GB/T 5023.1-2008 – Electrical cables and wires testing methods (China)

(3) ISO 6722 – Road vehicles — Electrical cables (International)

(4) ISO 14572 – Automotive wire performance testing (International)

(5) ISO 19642 – Electrical cable performance under low temperature (International)

(6) SAE J1128 – Low voltage primary cable standards (USA)

(7) QC/T 730 – Automotive cable standards (China)

(8) JASO D611-2009 – Automotive wire testing standard (Japan)

Parameters

| Parameter | Specification |

|---|---|

| Working temperature | -40℃ ± 1℃ |

| Mandrel diameter | D ≈ 4–5 × wire diameter |

| Sample diameter for winding | Φ2.5 – 12.5 mm |

| Winding speed | 1 turn / 6 seconds |

| Samples per cycle | 1 – 2 pcs |

| Winding rod diameters | Φ2.5, 4, 5, 6, 7, 10, 12, 14, 16, 18, 20, 24, 32, 35, 38, 50 mm (17 rods total) |

| Guide sleeve diameters | Φ1.2, 2, 2.5, 3.5, 5, 6, 10, 12, 14.5, 16 mm |

| Number of winding turns | 2 – 5 turns (time adjustable based on wire diameter; max ≤ 36s) |

| Operation method | Electric |

| Power supply | AC 220V ± 10%, 20A, 50Hz |

Features

Electric low-temperature operation ensures uniform and accurate test conditions.

Wide range of mandrels and guide sleeves accommodates various wire diameters.

Simulates bending, winding, and impact conditions for automotive wires.

Evaluates electrical and mechanical performance under extreme low temperatures.

Provides reliable testing for storage, transportation, and usage conditions.

Flexible test duration and winding turns, adjustable according to sample specifications.

Durable construction for long-term industrial use.

Accessories

(1) Main unit – 1 pc

(2) Winding rods set – 17 pcs

(3) Guide sleeves set – 10 pcs

(4) Product certificate – 1 pc

(5) User manual – 1 pc

(6) Delivery note – 1 pc

(7) Acceptance form – 1 pc

Test Procedures

Select and install the appropriate mandrel and guide sleeve for the sample wire.

Set the low-temperature chamber to -40℃ ± 1℃ and allow it to stabilize.

Install the wire or cable sample onto the mandrel.

Configure winding turns and duration according to the wire diameter.

Start the electric winding and low-temperature test.

Monitor the test until completion; the system evaluates mechanical and electrical performance.

Remove the sample and record any deformation, cracks, or performance changes.

Repeat as necessary for multiple samples.

Maintenance Information

Regularly inspect mandrels and guide sleeves for wear or deformation.

Keep the low-temperature chamber clean and free of frost or condensation.

Verify calibration periodically to ensure accurate temperature control and winding speed.

Lubricate moving components according to manual instructions.

Store in a dry, dust-free environment when not in use.

FAQ

What is this product?

An electric low-temperature tester for winding and impact testing of wires, cables, and electrical components.

What is it used for?

To evaluate low-temperature bending, winding, and impact resistance of wires and cables.

Why is it important?

Ensures that automotive and electrical wires maintain mechanical and electrical performance under extreme cold conditions.

Which industries is it suitable for?

Automotive, electrical, electronics, instrumentation, and cable manufacturing industries.

What types of products can be tested?

Automotive wires, electrical cables, and related components, including insulated and uninsulated wires.

Leave Message Get Price